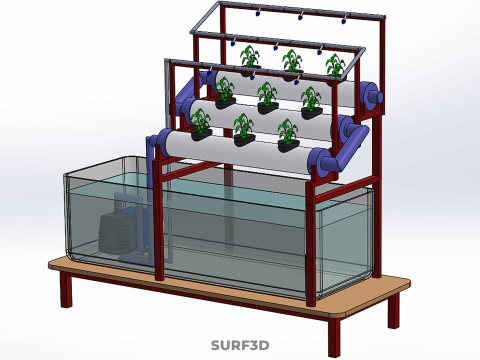

UPRAWA ROŚLIN HYDROPONICZNY CYKL WODNY ZBIORNIK POMPA DYSZA ROZPYLACZ Model 3D

- Poproś autora o wsparcie produktu

- Dostępne formaty:

- ID produktu:594857

- Data: 2025-08-26

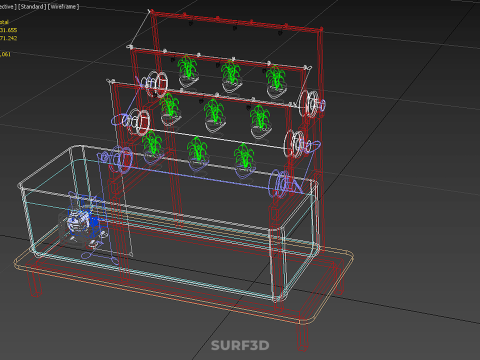

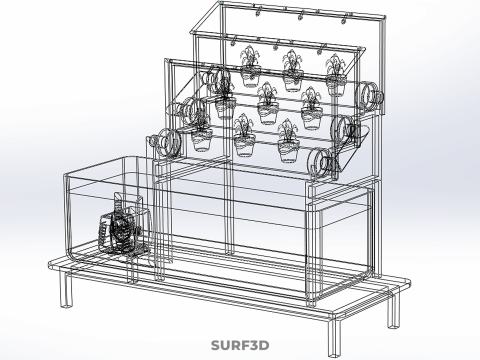

- Wielokąty:231655

- Wierzchołki:171242

- Model animowany:No

- Tekstury:No

- Oparty na szkielecie:No

- Materiał:

- Low-poly:No

- Kolekcja:No

- UVW mapping:No

- Plugins Used:No

- Gotowy do wydruku:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Szkolenie:No

- Geometria:Poly NURBS

- Unwrapped UVs:Unknown

- Liczba wyświetleń:245

Opis

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

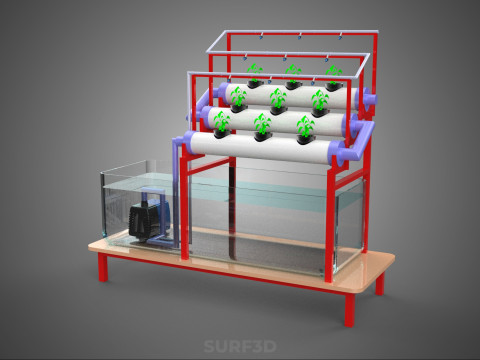

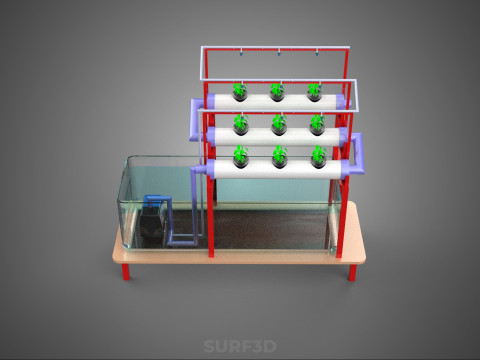

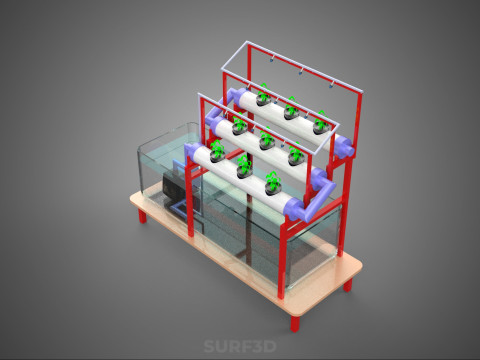

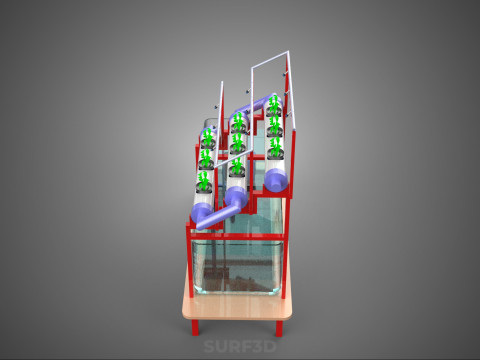

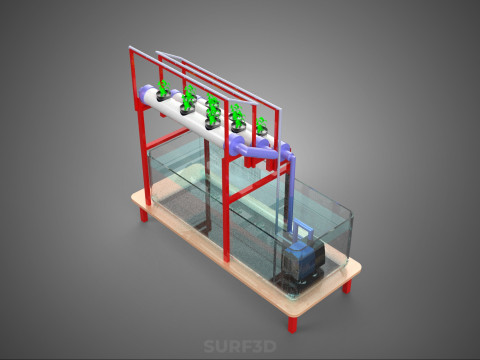

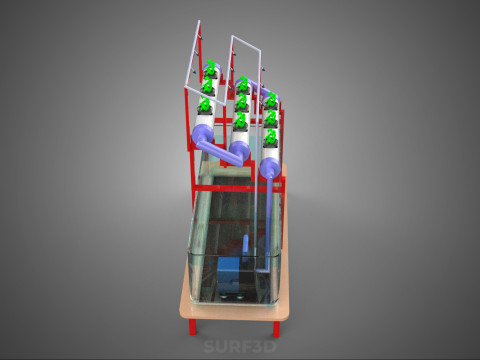

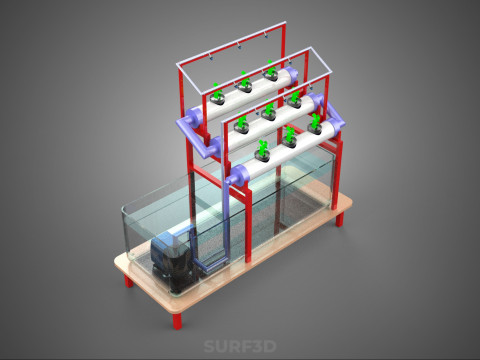

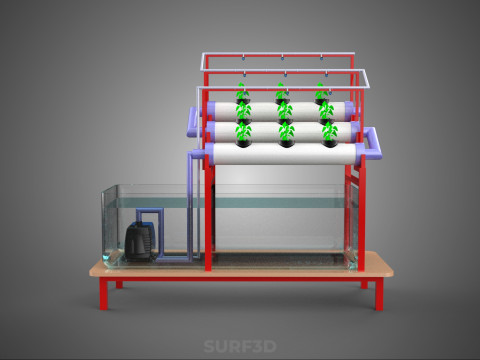

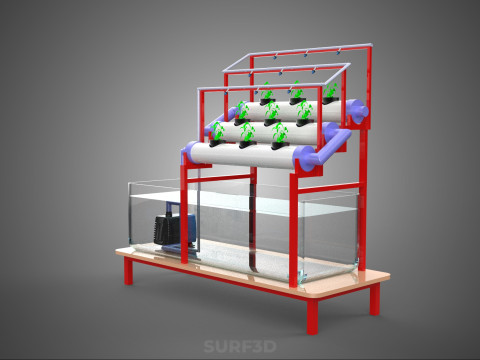

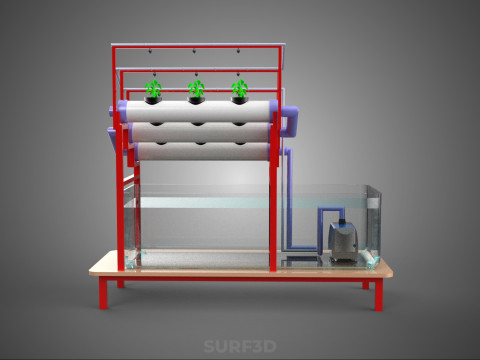

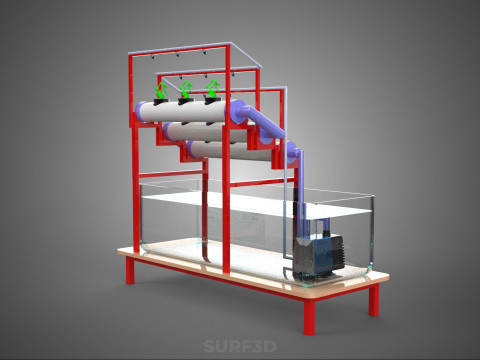

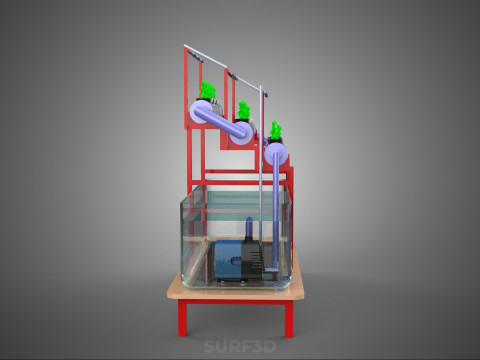

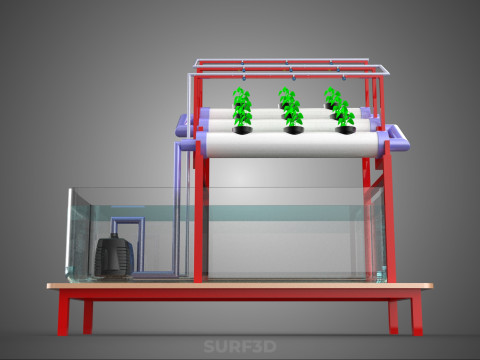

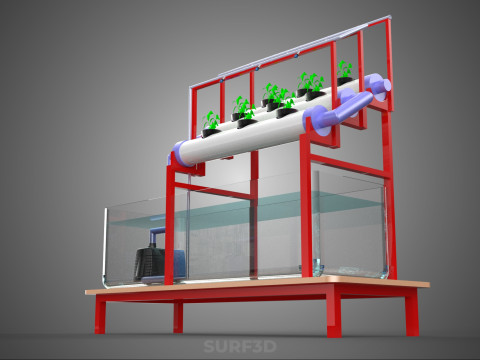

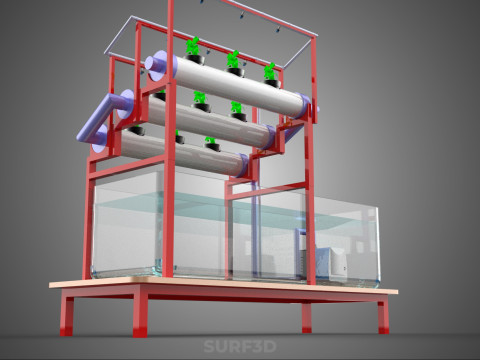

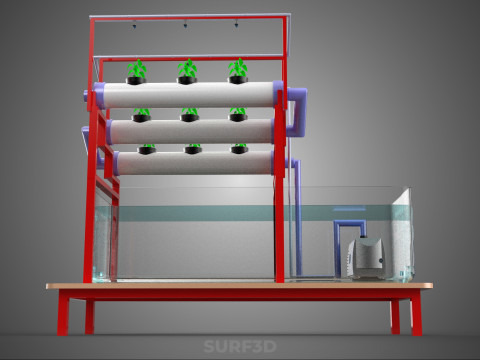

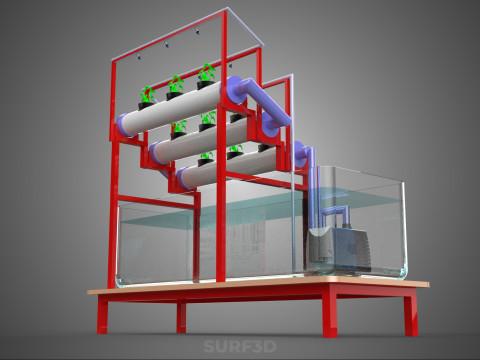

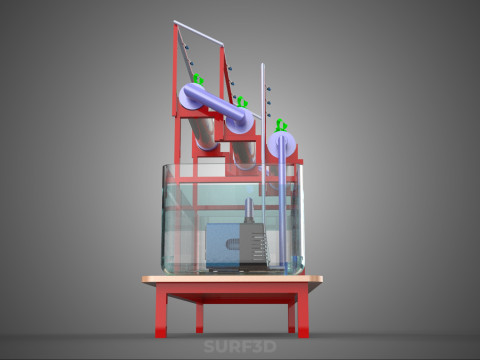

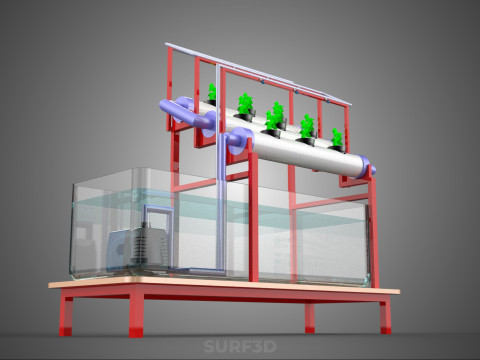

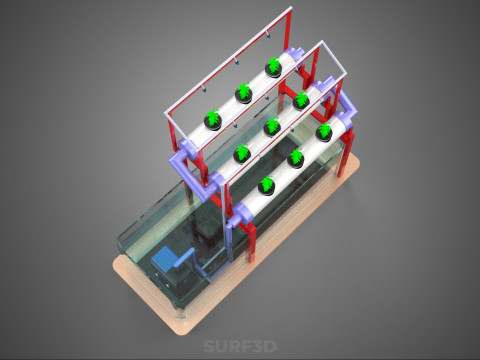

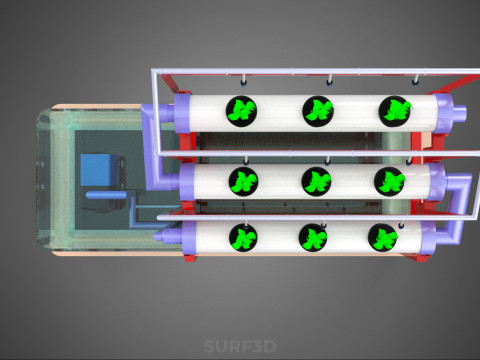

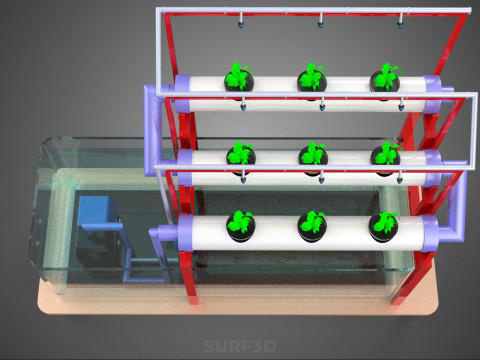

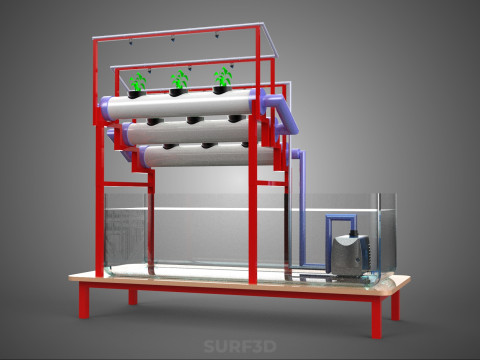

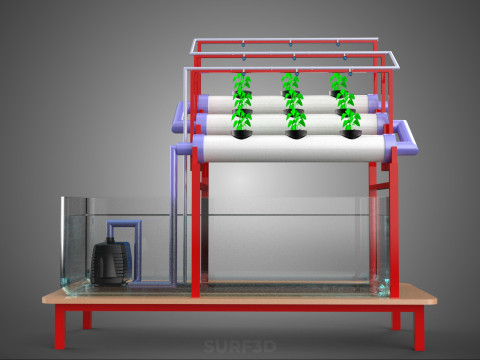

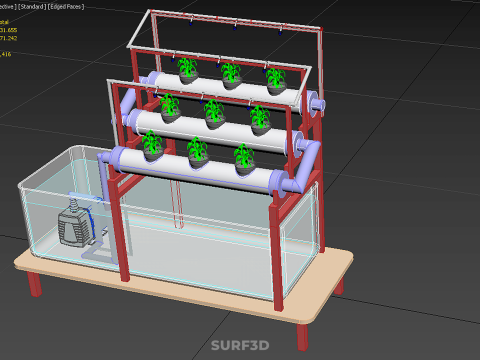

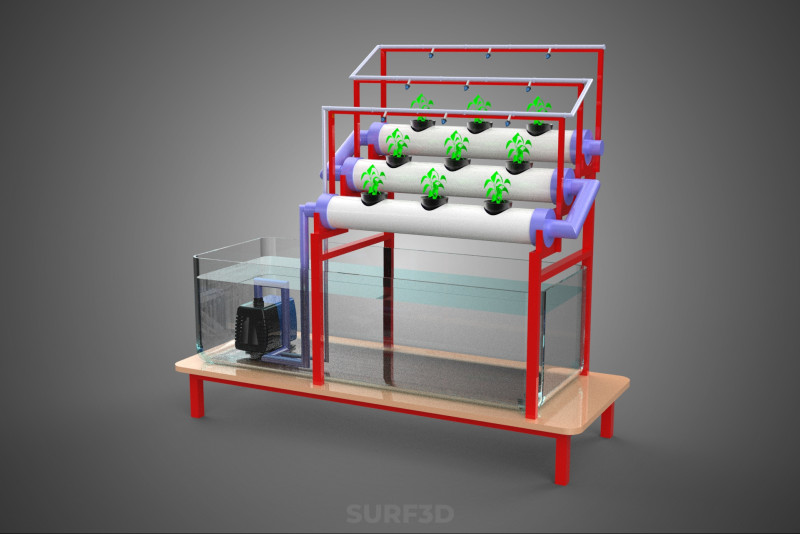

## Plant Cultivation Hydroponic Water Cycle Tank System with Submersible Pump and Nozzle Spray

This detailed description outlines a specialized system designed for **plant cultivation** utilizing **hydroponic** principles, centered around a **water cycle tank** equipped with a **submersible pump** that actively **supplies water** via a **nozzle spray** mechanism as an **additional feature**. This integrated setup is engineered to optimize nutrient delivery and resource efficiency in soilless horticultural environments.

### 1. Overview of Hydroponic Cultivation

Hydroponics is a method of growing plants without soil, using mineral nutrient solutions dissolved in water to deliver essential elements directly to the root system. This approach offers several advantages, including accelerated growth rates, reduced water consumption, efficient nutrient utilization, and diminished incidence of soil-borne diseases. The described system represents a sophisticated implementation within this broader discipline, focusing on precise and recirculating nutrient delivery.

### 2. Core Components and Functionality

The system comprises several interconnected components that facilitate a continuous and controlled environment for plant growth:

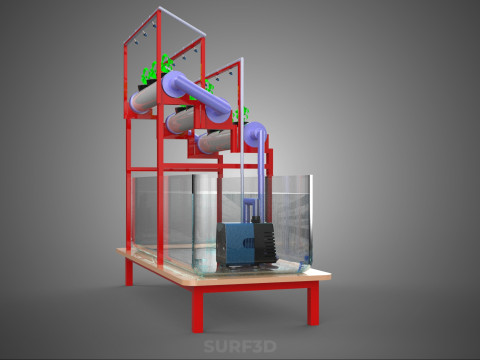

#### 2.1. Water Cycle Tank (Reservoir)

The water cycle tank serves as the primary reservoir for the nutrient solution. This tank is typically constructed from opaque, food-grade material to prevent light ***********, which inhibits algal growth, and to ensure the chemical stability of the nutrient solution. Its volume is carefully selected based on the scale of the cultivation operation, ensuring sufficient capacity for the plants' needs while minimizing the frequency of refilling. The tank is integral to the "water cycle" aspect, as it collects and re-stores the drained nutrient solution for recirculation, thereby conserving water and nutrients.

#### 2.2. Submersible Pump

A submersible pump is positioned within the water cycle tank. Its primary function is to draw the nutrient solution from the reservoir and propel it through a delivery network to the plant root zones. Submersible pumps are favored in hydroponic systems due to their quiet operation, efficient heat dissipation into the water, and reduced risk of leaks compared to external pumps. The pump's flow rate and head pressure are critical parameters, selected to match the specific requirements of the chosen nutrient delivery method and the overall system design. The continuous operation of the pump is typically controlled by a timer to regulate irrigation cycles, ensuring plants receive optimal hydration and nutrition without oversaturation.

#### 2.3. Nozzle Spray (Additional Feature for Water Supply)

The nozzle spray represents a crucial "additional feature" for the precise and effective delivery of the nutrient solution. Connected to the discharge outlet of the submersible pump, these nozzles convert the pressurized flow of nutrient solution into a fine mist or targeted spray. The specific design and orifice size of the nozzles vary based on the application:

* **Aeroponic Systems:** Fine misting nozzles (foggers) create a highly oxygenated environment around suspended roots, maximizing nutrient uptake and accelerating growth.

* **Deep Water Culture (DWC) or Nutrient Film Technique (NFT) Supplemental:** While not the primary delivery method for all DWC/NFT systems, spray nozzles can be strategically placed to ensure even saturation of grow media, provide supplementary aeration, or facilitate top-feeding in certain configurations.

* **General Hydroponic Irrigation:** Larger spray nozzles or micro-sprinklers can be used to irrigate grow beds, ensuring uniform distribution of the nutrient solution across the root zone.

The spray mechanism ensures high surface area contact between the nutrient solution and the roots, promoting efficient absorption and often enhancing root oxygenation. It also facilitates precise control over the amount and timing of nutrient delivery, minimizing waste and optimizing plant health.

### 3. Operational Cycle and Benefits

The operational cycle begins with the submersible pump drawing nutrient solution from the water cycle tank. The pump then forces this solution through tubing or piping to the strategically placed nozzle sprays, which deliver it directly to the root zone of the plants or onto their growing medium. Any excess solution that is not absorbed by the plants or retained by the medium drains back into the water cycle tank, completing the closed-loop recirculation.

This integrated system offers several significant advantages:

* **Water and Nutrient Conservation:** The closed-loop design drastically reduces water and nutrient wastage compared to traditional soil-based or non-recirculating hydroponic systems.

* **Optimized Nutrient Delivery:** The precise control offered by the nozzle spray ensures uniform distribution and enhanced oxygenation, leading to more efficient nutrient uptake and faster plant growth.

* **Reduced Disease Risk:** By eliminating soil and maintaining a sterile, controlled environment, the system mitigates the risk of soil-borne pathogens.

* **Scalability and Adaptability:** The modular nature of these components allows for scalability, from small hobbyist setups to large commercial farms, and adaptability to various plant types and hydroponic methodologies.

* **Environmental Control:** The consistent delivery of nutrients and water contributes to a stable root environment, which is crucial for optimal plant health and yield.

### 4. Maintenance and Considerations

Effective operation requires regular monitoring of nutrient solution parameters (pH, Electrical Conductivity (EC)), periodic cleaning of the tank and system components to prevent biofilm and algal buildup, and inspection/cleaning of the nozzles to prevent clogging from mineral deposits or particulate matter. The quality of the pump and the robustness of the nozzle system are critical for reliable, long-term performance.

Potrzebujesz plik w innym formacie?

Jeśli potrzebny Ci plik w innym formacie, zgłoś taką potrzebę przez opcję Support Ticket Konwertujemy produkty na następujące formaty: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Dowolna konwersja formatuNie konwertujemy scen 3D oraz formaty takie jak .step, .iges, .stp, .sldprt.!

Informacje o użytkowaniu

UPRAWA ROŚLIN HYDROPONICZNY CYKL WODNY ZBIORNIK POMPA DYSZA ROZPYLACZ - Możesz używać tego bezpłatnego modelu 3D zarówno do celów osobistych, jak i komercyjnych, zgodnie z Licencją Podstawową lub Rozszerzoną.Licencja Podstawowa obejmuje większość standardowych przypadków użycia, w tym reklamy cyfrowe, projekty projektowe i wizualizacyjne, firmowe konta w mediach społecznościowych, aplikacje natywne, aplikacje internetowe, gry wideo oraz fizyczne lub cyfrowe produkty końcowe (zarówno bezpłatne, jak i sprzedawane).

Licencja Rozszerzona obejmuje wszystkie prawa udzielone na mocy Licencji Podstawowej, bez ograniczeń użytkowania i pozwala na wykorzystanie modelu 3D w nieograniczonej liczbie projektów komercyjnych na warunkach bezpłatności.

Czytaj więcej

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी