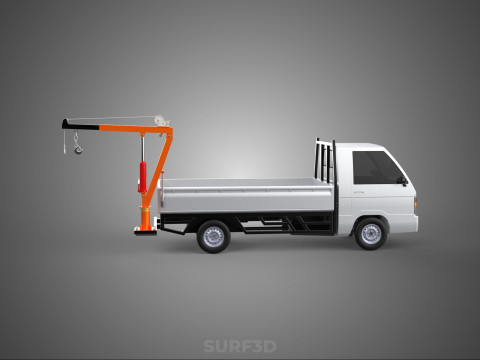

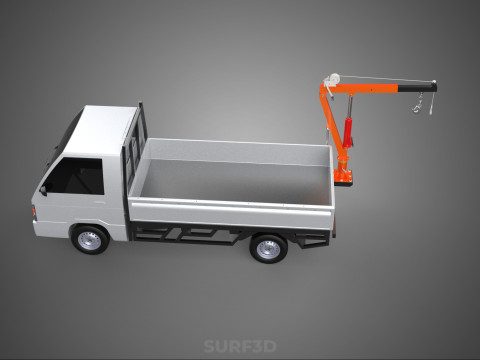

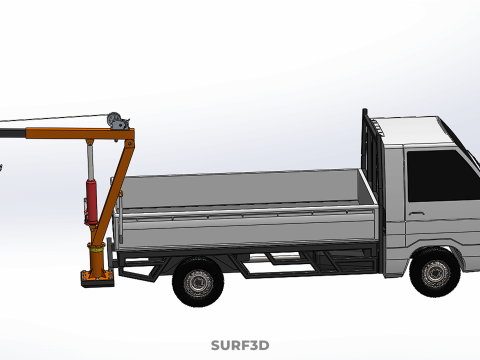

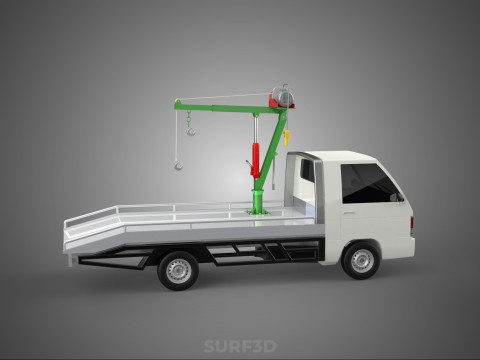

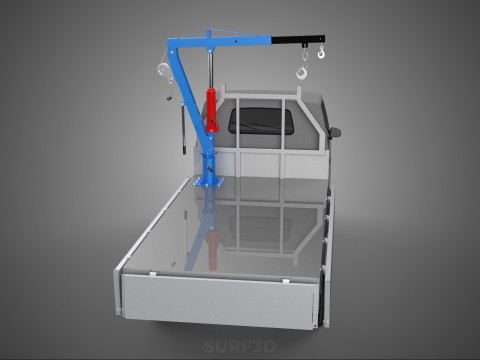

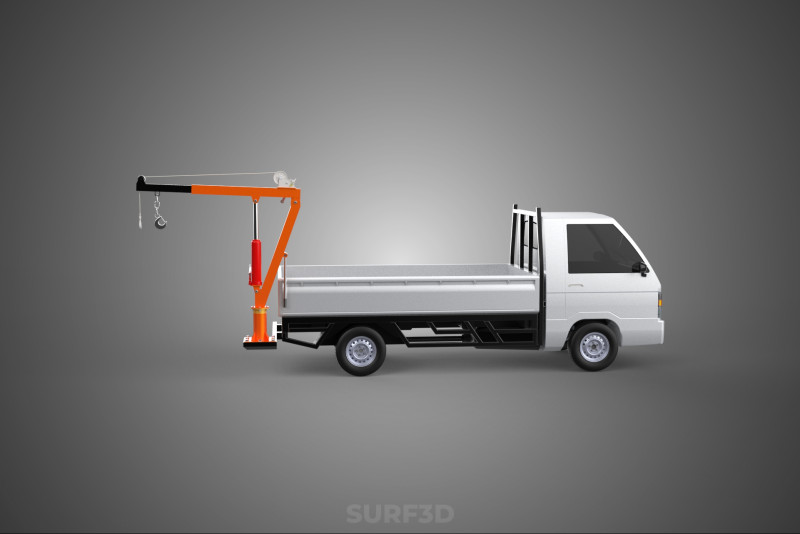

FOLDABLE MOUNTED BED CRANE HOIST LIFTING HAND WINCH PICKUP TRUCK Modello 3D

- Formati disponibili: Collada (.dae) 12.91 MBSTEP (.step) 7.77 MBWavefront OBJ (.obj) 9.96 MBGLB (.glb / .gltf) 6.40 MBStereolithography (.stl) 10.39 MBBlender3D (.blend) 13.14 MBAutodesk AutoCAD (.dwg) 18.91 MB3D Studio (.3ds) 4.89 MBAutodesk FBX (.fbx) 16.82 MBAutodesk 3DS MAX (.max) 27.77 MBSketchUp (.skp) 12.38 MBACIS(.sat) 15.84 MBRhinoceros (.3dm) 33.06 MBIGES (.iges) 8.17 MB

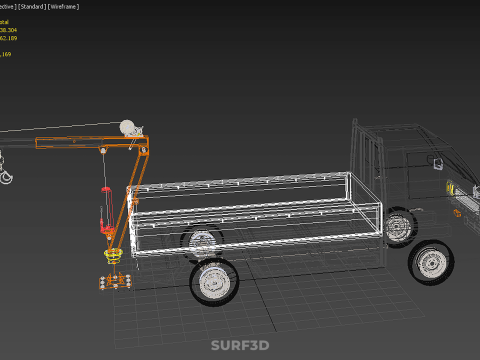

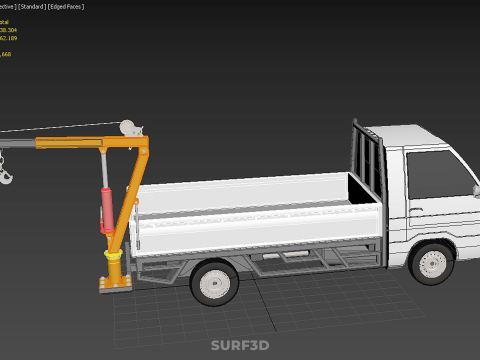

- Pligoni:738304

- Vertici:562189

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- AI Formazione:No

- Geometria:Poly NURBS

- UVs Aperti:Unknown

- Visualizzazioni:150

- Data: 2025-08-18

- ID Oggetto:593120

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A foldable mounted bed crane hoist, equipped with a hand crank winch and attached to a pickup truck, is a specialized lifting apparatus designed for the manual handling and transport of heavy or bulky objects. This versatile system integrates a robust, articulated crane structure directly into the cargo bed of a light-duty truck, providing a self-contained solution for loading, unloading, and positioning materials without the need for external power sources or dedicated heavy machinery. Its design emphasizes portability, ease of storage, and operational independence, making it highly suitable for various industrial, commercial, agricultural, and recreational applications where access to powered lifting equipment is limited or impractical.

**Design and Components**

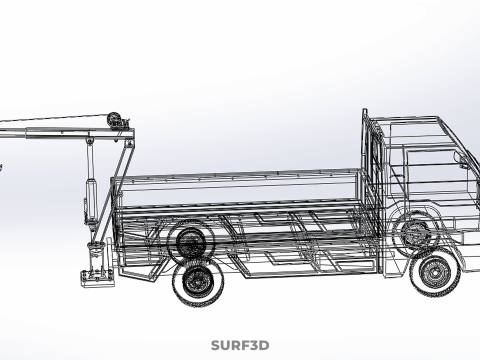

The fundamental design of this system comprises several interconnected components engineered for robustness and functional efficiency:

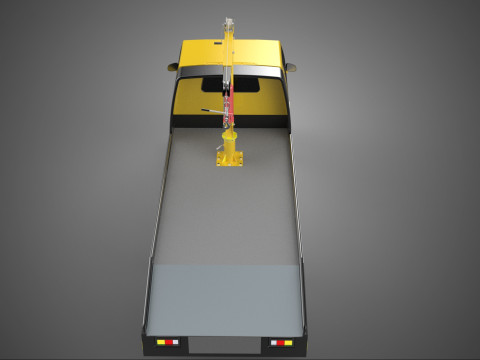

* **Mounting System:** The crane's base is engineered for secure attachment to the pickup truck bed, typically through bolt-down plates, stake pocket inserts, or a receiver hitch mount. This robust connection ensures stability during lifting operations by distributing the load across the truck's frame and bed structure. The mounting point often incorporates a slewing bearing or pivot mechanism, allowing the crane boom to rotate horizontally through a wide arc, commonly 360 degrees, for optimal load placement and access from various angles around the truck.

* **Crane Structure (Boom and Mast):** Constructed from high-strength steel or aluminum alloys, the crane's primary structure consists of a vertical mast, which anchors to the base, and a horizontally extending boom (jib). The boom is frequently telescopic, allowing for variable reach and improved versatility in handling different load sizes and positioning requirements. The entire assembly is designed to withstand significant dynamic and static loads, with rated capacities varying widely based on model, typically ranging from a few hundred pounds to over a thousand pounds.

* **Foldable Mechanism:** A distinguishing feature of this crane is its ability to fold or collapse into a compact form. This is achieved through articulated joints and robust pinning systems that allow the boom and, in some designs, the mast to fold downwards or inwards. This compact configuration significantly reduces the crane's footprint when not in use, preserving valuable truck bed space for other cargo and facilitating storage in garages or workshops with limited overhead clearance. The folding mechanism enhances the truck's everyday utility without requiring the permanent dedication of significant cargo area.

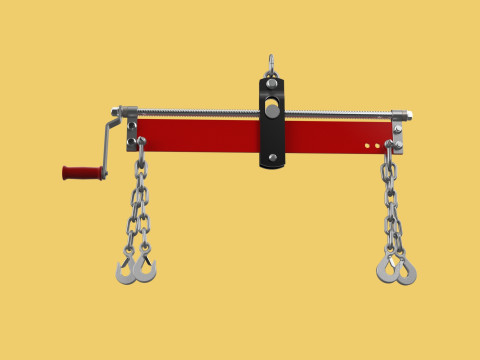

* **Lifting Mechanism (Hoist):** The lifting action is performed by a durable cable or synthetic rope system, which spools onto the winch drum. The cable runs over one or more sheaves (pulleys) located at the end of the boom, providing mechanical advantage and guiding the lift hook vertically. The hook typically includes a safety latch to prevent accidental disengagement of the load during lifting and lowering operations.

* **Hand Crank Winch:** The power source for the hoist is a robust, manually operated hand crank winch. This mechanism consists of a gear train and a drum around which the lifting cable or rope is wound. The operator turns a handle, which, through the gearing, rotates the drum, thereby raising or lowering the load. The winch is typically equipped with a self-locking or ratchet mechanism, such as a worm gear or a pawl and gear system, to securely hold the load at any desired height, preventing unintentional descent. This manual operation eliminates the need for electrical power or hydraulic systems, simplifying the design, enhancing reliability in remote or off-grid environments, and reducing the overall cost and maintenance requirements.

**Operational Principles**

Operation involves securely mounting the crane to the truck bed, extending the boom to the desired reach and angle, attaching the load to the hook, and then manually turning the hand crank winch. The gear ratio of the winch determines the effort required versus the speed of the lift; a higher ratio provides greater mechanical advantage (less effort) but results in slower lifting speeds. Prior to operation, it is crucial to consult the manufacturer's load chart, which specifies safe working loads at different boom extensions and angles to ensure vehicle stability and prevent overloading. For optimal safety, the truck's parking brake should be engaged, and the vehicle ideally placed on level, stable ground to maximize stability during lifting.

**Applications**

The foldable mounted bed crane with a hand crank winch finds extensive utility across diverse sectors:

* **Construction and Trades:** Facilitates the loading and unloading of building materials, heavy tools, generators, compressors, and small machinery at job sites.

* **Agriculture:** Used for moving feed bags, engine parts, small implements, or harvested goods on farms and ranches.

* **Landscaping:** Aids in lifting and positioning large rocks, bags of soil, bulk aggregates, or cut timber.

* **Automotive:** Provides a practical solution for removing or installing engines, transmissions, or other heavy automotive components.

* **Recreational:** Manages heavy equipment for camping, hunting, or off-roading, such as generators, large coolers, or ATVs (with appropriate rigging).

* **General Utility:** Applicable in any scenario requiring the lifting and precise placement of moderately heavy objects where conventional forklifts or powered cranes are impractical, unavailable, or cost-prohibitive.

**Advantages**

Key advantages of this system include its self-contained nature, requiring no external power source; its inherent portability, as it travels seamlessly with the pickup truck; its relative affordability compared to powered lifting solutions; its simplicity of operation and maintenance; and its foldable design, which uniquely preserves truck bed utility when the crane is not in active use.

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Non convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी