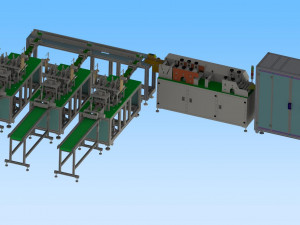

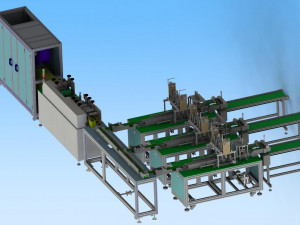

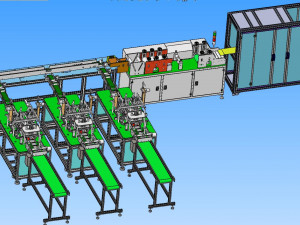

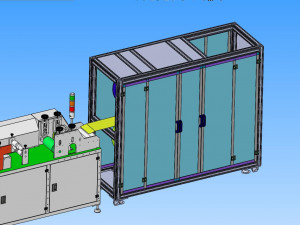

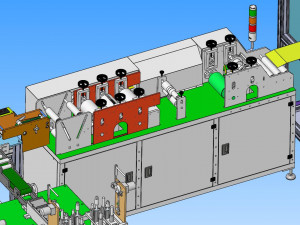

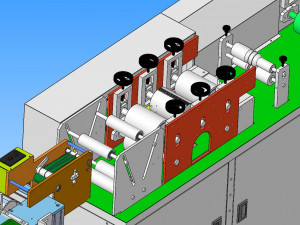

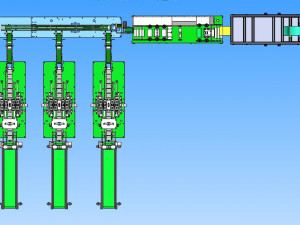

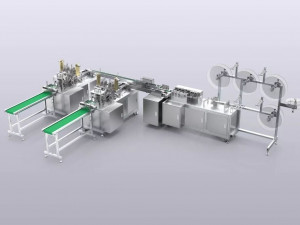

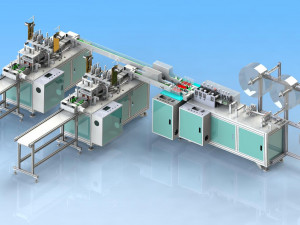

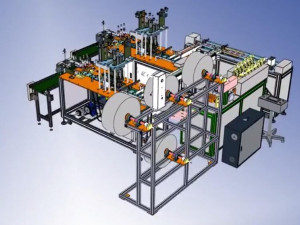

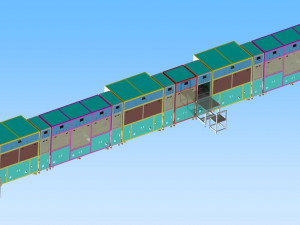

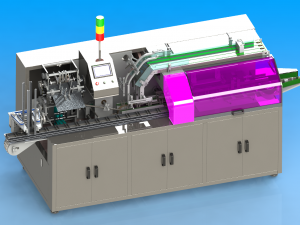

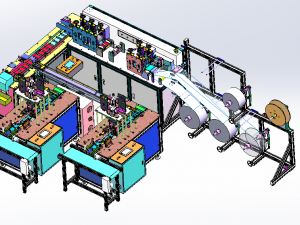

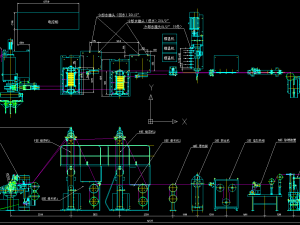

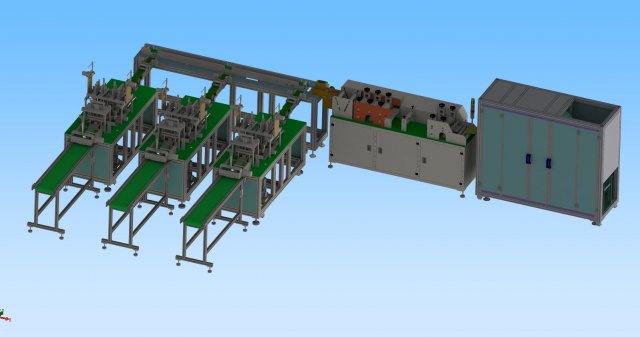

production line of six generation one drag three mask machine Modello 3D

CYBER MONDAY

SALE 50% OFF

$

24.50 USD

- Richiedi supporto per il prodotto

- Formati disponibili:

- ID Oggetto:311095

- Data: 2020-09-14

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- Geometria:Polygonal

- UVs Aperti:Unknown

- Visualizzazioni:3725

Descrizione

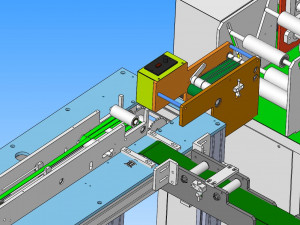

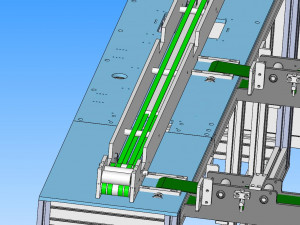

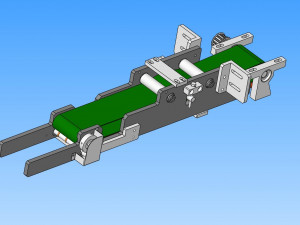

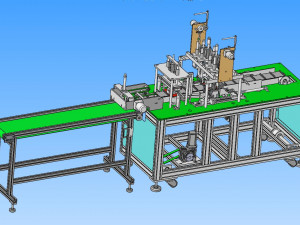

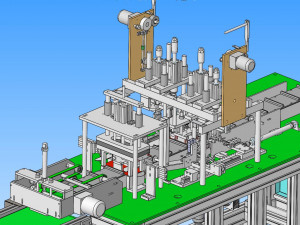

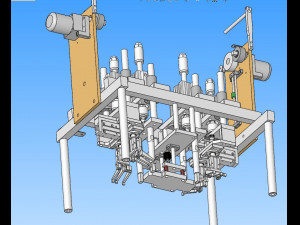

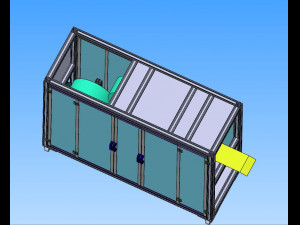

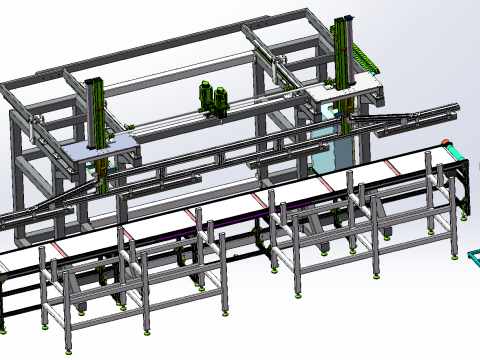

the automatic production line of three masks is composed of one mask body machine and three ear band welding machines. 160-180 pieces of complete flat face mask can be produced per minute. the mask specification is: 175 x 95mm three-layer non-woven fabric plane filter mask. compared with a single stand-alone mask manufacturing machine, automatic conveyor belt and port are added. in addition to improving production efficiency and reducing labor costs, this unique design is designed to minimize manual participation and reduce the risk of mask contamination in the production process.this production line is a fully automatic one drag three mask machine, one body machine drives three ear belt machines. after the mask body is output by the body machine, the mask body piece is transported to the turnover mechanism by the conveyor belt structure, and the mask disc is turned over to the conveyor belt connected with the ear belt machine through the turnover mechanism, and then the mask piece is transported to the top of the first mask disc on the front of the ear belt machine through the conveyor belt, and the mask piece is finally placed into the mask disc of the ear belt machine by the cylinder downward pressure, and then completed by the ear belt machine the ear belt of the mask is fused, hemmed and so on, so as to complete the production of an ear band mask product. Stampa Pronta: No

Hai bisogno di ulteriori formati?

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Conversione di formato gratuitaNon convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

Informazioni sull'utilizzo

production line of six generation one drag three mask machine - È possibile utilizzare questo modello 3D royalty-free sia per scopi personali che commerciali, in conformità con la licenza base o estesa.La licenza base copre la maggior parte dei casi d'uso standard, tra cui pubblicità digitale, progetti di design e visualizzazione, account aziendali sui social media, app native, app web, videogiochi e prodotti finali fisici o digitali (sia gratuiti che venduti).

La licenza estesa include tutti i diritti concessi dalla licenza base, senza limitazioni d'uso, e consente l'utilizzo del modello 3D in un numero illimitato di progetti commerciali secondo i termini royalty-free.

Leggi ulteriori

Offrite la garanzia di rimborso?

Sì, la offriamo. Se hai acquistato un prodotto e hai riscontrato degli errori nei renders o nella descrizione, proveremo a risolvere al più presto il problema. Se non possiamo correggere l'errore, annulleremo l'ordine e ti restituiremo i soldi entro 24 ore dal download dell'oggetto. Leggi le condizioni quiParole chiave

Oggetti casuali dall'autore

Nessun commento per quest'oggetto.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी