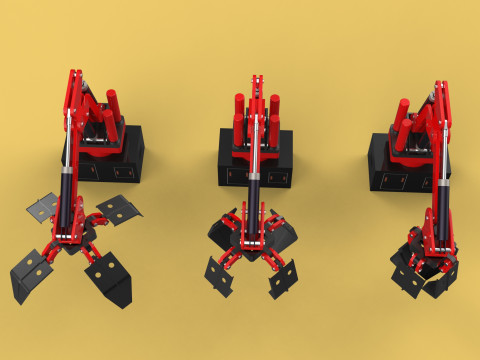

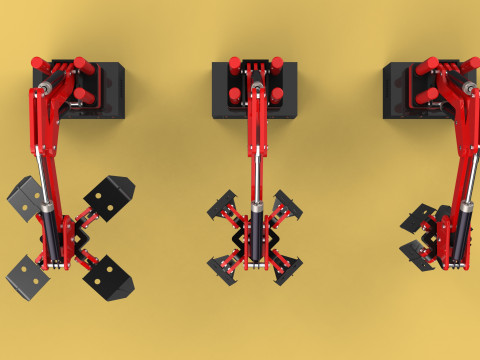

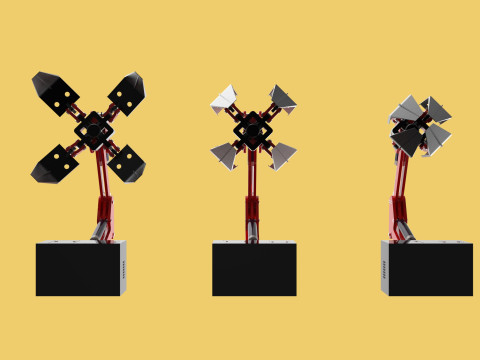

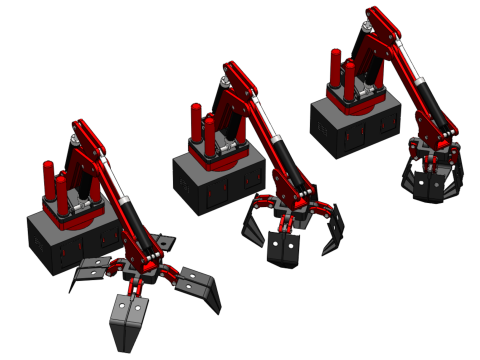

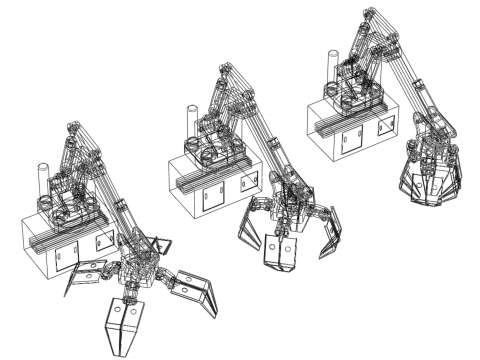

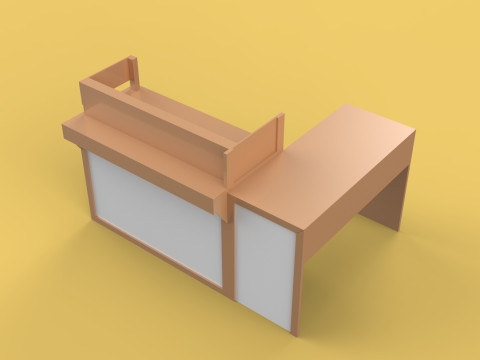

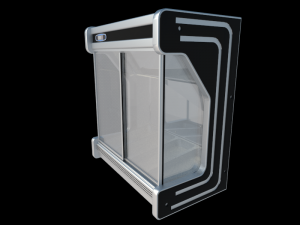

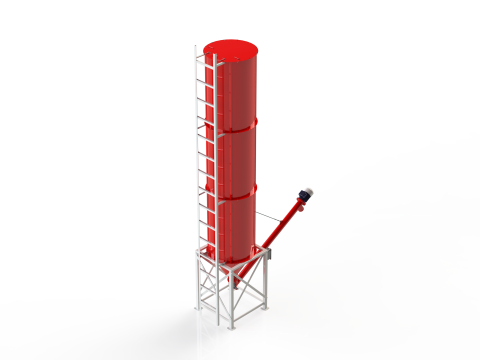

アームローダーリフティングクレーングラバーグラップルフックジョートングフック自動 3Dモデル

- 利用可能フォーマット: Rhinoceros (.3dm) 2.38 MB3D Studio (.3ds) 1.31 MBBlender3D (.blend) 3.06 MBAutodesk AutoCAD (.dwg) 2.25 MBAutodesk FBX (.fbx) 4.16 MBIGES (.iges) 631.12 kbAutodesk 3DS MAX (.max) 5.99 MBWavefront OBJ (.obj) 2.26 MBACIS(.sat) 2.71 MBSketchUp (.skp) 672.79 kbSTEP (.step) 557.97 kbStereolithography (.stl) 2.52 MB

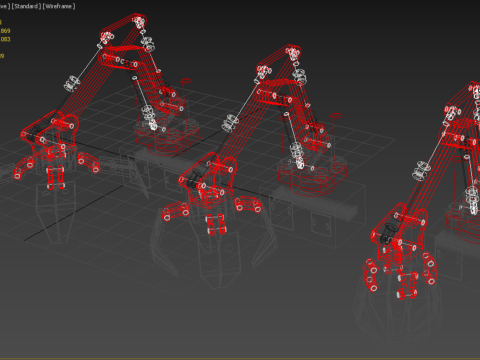

- 多角形:196869

- 頂点:181083

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:1166

- 日付: 2025-04-30

- アイテム ID:570835

アームローダーリフティングクレーングラバーグラップルフックジョートングフック自動 3Dモデル 3dm, 3ds, blend, dwg, fbx, iges, max, obj, sat, skp, step, stl, から surf3d

The model contains the most popular formats:

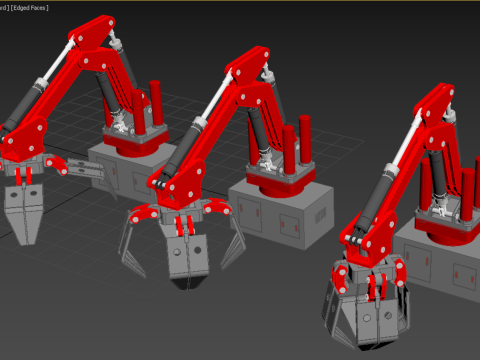

1. 3DS MAX: *.max

2. Blender: *.blend

3. Rhinoceros: *.3dm

4. SketchUp: *.skp

5. Wavefront OBJ: *.obj *.mtl (Multi Format)

6. FBX: *.fbx (Multi Format)

7. STEP: *.step *.stp (NURBS)

8. IGES: *.iges *.igs (NURBS)

9. ACIS: *.sat (NURBS)

10. 3DS MAX all ver.: *.3ds (Multi Format)

11. Stereolithography: *.stl

12. AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

Sincerely Your, SURF3D

MORE INFORMATION ABOUT 3D MODELS :

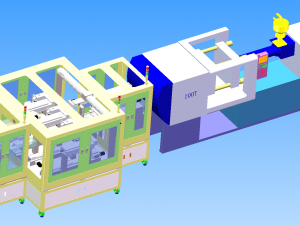

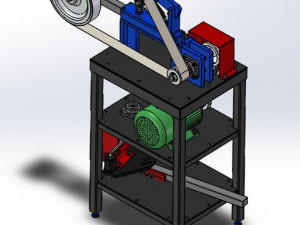

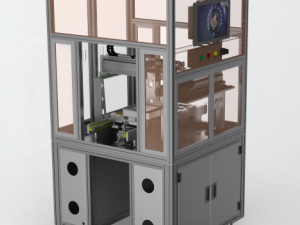

AUTO ARM LOADER LIFTING CRANE: Versatile and Automated Material Handling

This describes an automated arm loader lifting crane designed for efficient and often repetitive material handling tasks. The terms grabber, grapple, hook, jaw, and tong highlight the various types of end-effectors (the part that interacts with the load) it can utilize, while "auto" signifies its automated or semi-automated operation.

Key Features and Functionality:

Automated Operation (Auto): This is a key differentiator, implying the crane can perform lifting and manipulation tasks with minimal or no direct human intervention after initial programming or setup. This automation can involve pre-programmed sequences, sensor-based responses, or integration with robotic systems.

Arm Loader Design: Features an articulated arm structure, similar to a robotic arm, providing a wide range of motion and reach. This allows it to access and manipulate objects in complex environments.

Lifting Crane Functionality: Capable of lifting and lowering various loads within its specified capacity.

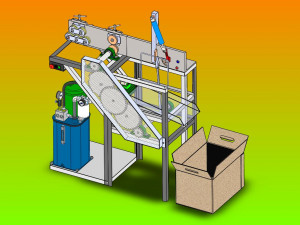

Versatile End-Effectors: Designed to be compatible with a variety of interchangeable end-effectors to handle different types of materials and tasks:

Grabber/Grapple: For securely grasping irregular or bulky objects.

Hook: For lifting items with dedicated lifting points or using slings.

Jaw/Tong: For gripping and manipulating specific shapes or materials, often with a pincer-like action.

Automated Control System: Utilizes sensors, actuators, and a control system (PLC, microcontroller, or industrial robot controller) to execute pre-programmed movements and respond to environmental cues.

Precision and Repeatability: Automation allows for highly precise and repeatable movements, crucial for tasks like assembly or precise placement.

Safety Features: Incorporates various safety mechanisms, such as obstacle detection, emergency stops, and programmed motion limits, to ensure safe operation.

Power Source: Typically powered by electricity or hydraulics, depending on the size and application.

Benefits:

Increased Efficiency: Automates repetitive tasks, leading to faster cycle times and higher throughput.

Reduced Labor Costs: Minimizes the need for manual labor in material handling.

Improved Safety: Reduces the risk of human injury associated with manual lifting and handling of heavy or hazardous materials.

Enhanced Precision and Quality: Automated movements ensure consistent and accurate placement of objects.

Flexibility and Adaptability: The ability to change end-effectors allows the crane to handle a wide variety of tasks.

Integration with Other Systems: Can be integrated with conveyors, automated storage and retrieval systems (AS/RS), and other automated equipment.

Potential Applications:

Automated manufacturing and assembly lines.

Robotic material handling in warehouses and distribution centers.

Pick-and-place operations.

Machine tending (loading and unloading machines).

Handling hazardous materials.

Automated sorting and packaging systems.

In summary, an auto arm loader lifting crane is a sophisticated and versatile automated material handling solution. Its articulated arm, interchangeable end-effectors, and intelligent control system enable efficient, precise, and safe handling of a wide range of objects in various industrial and logistical applications.

フォーマットが必要ですか?

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!使用情報

アームローダーリフティングクレーングラバーグラップルフックジョートングフック自動 - このロイヤリティフリーの3Dモデルは、基本ライセンスまたは拡張ライセンスに従って、個人および商用目的で使用できます。基本ライセンスは、デジタル広告、デザインおよび視覚化プロジェクト、ビジネスソーシャルメディアアカウント、ネイティブアプリ、ウェブアプリ、ビデオゲーム、物理またはデジタル最終製品(無料および有償)など、ほとんどの標準的な使用事例をカバーしています。

拡張ライセンスには、基本ライセンスで付与されるすべての権利が使用制限なしで含まれており、ロイヤリティフリーの条件の下で、3Dモデルを無制限の商用プロジェクトで使用できます。

詳細を読む

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी