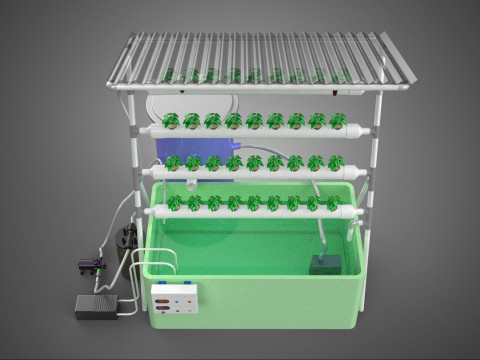

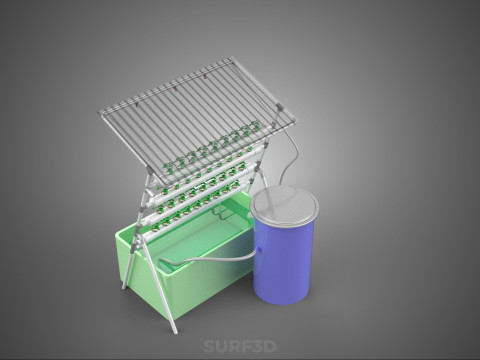

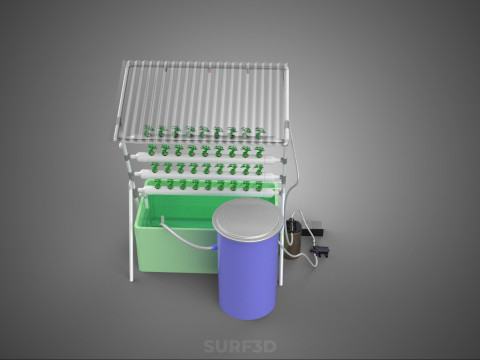

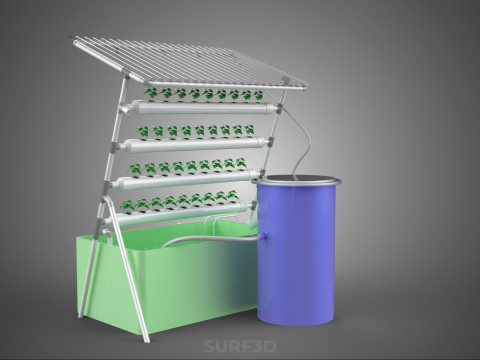

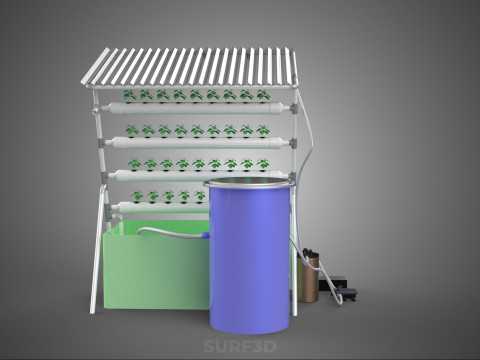

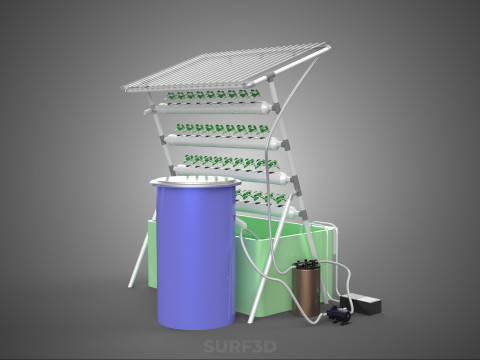

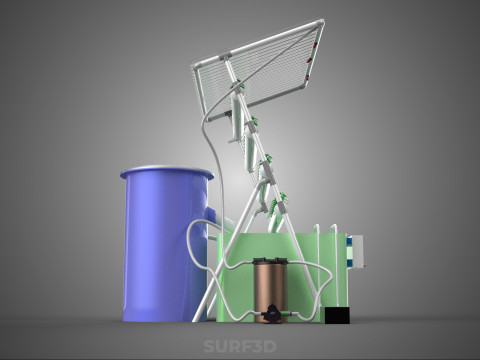

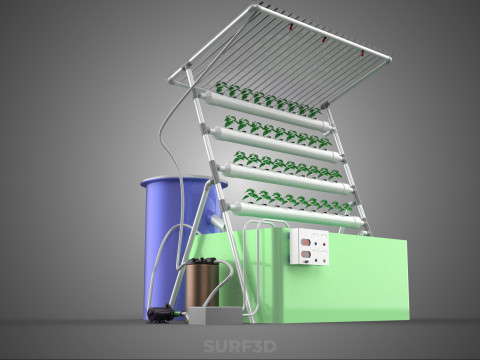

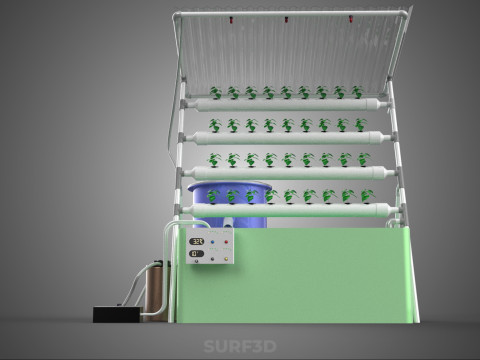

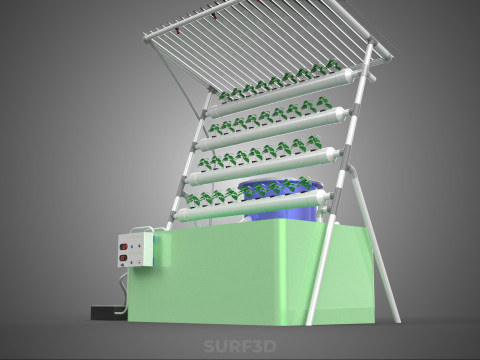

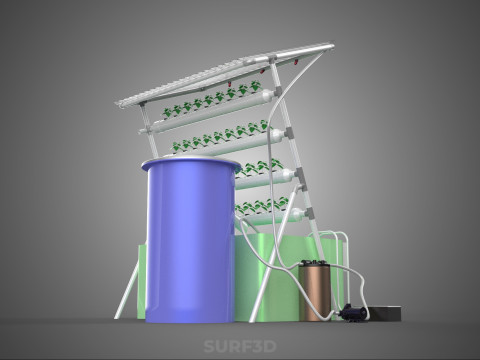

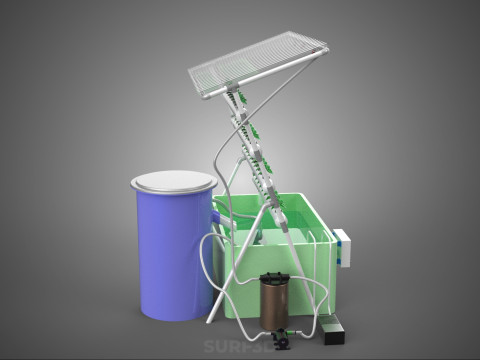

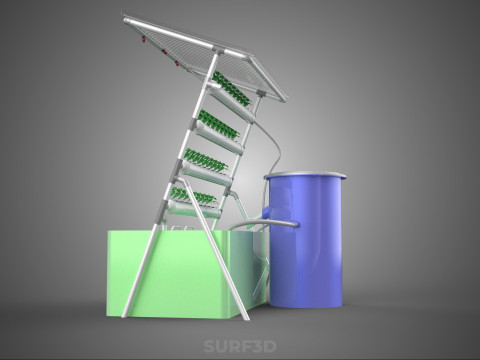

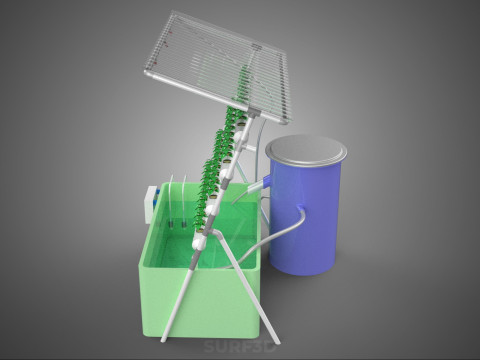

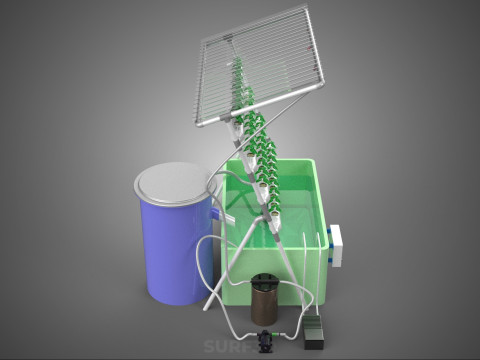

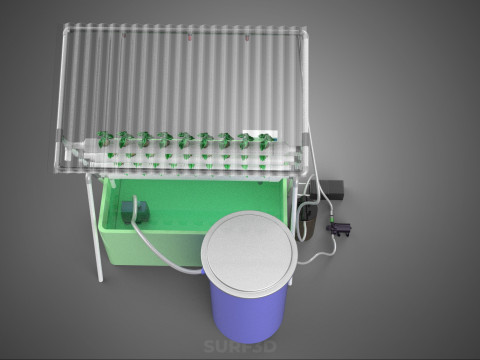

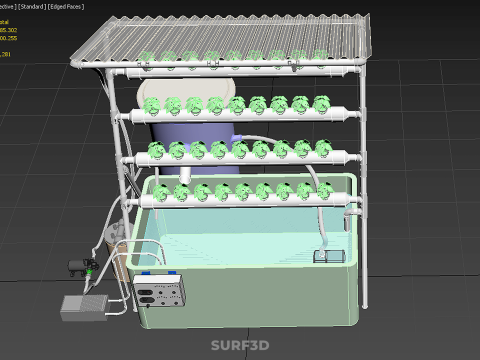

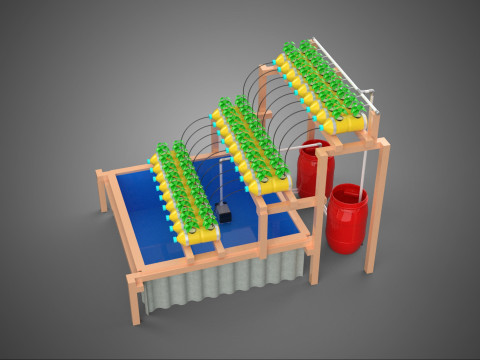

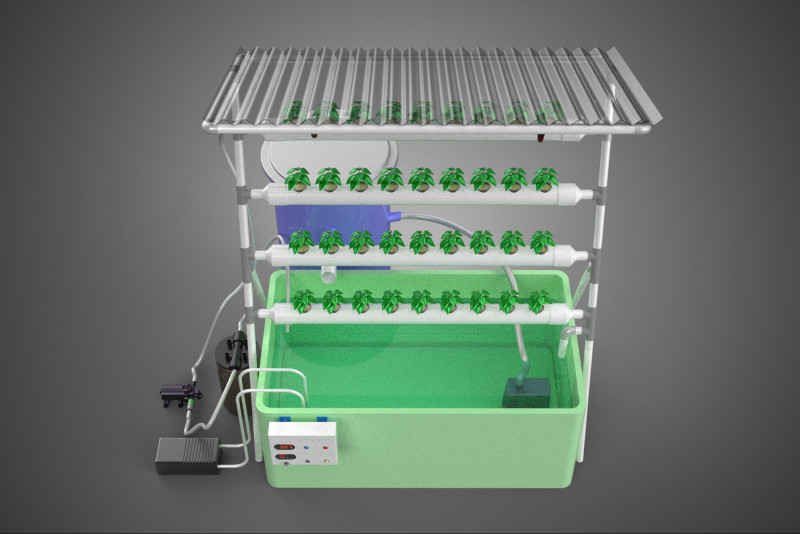

IOT水耕栽培プラント自動制御水循環ポンプノズルスプレー 3Dモデル

- 作者による製品サポートのリクエスト

- 利用可能フォーマット:

- アイテム ID:600089

- 日付: 2025-09-19

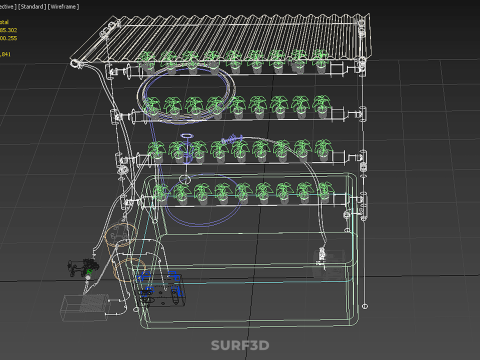

- 多角形:885302

- 頂点:600255

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:272

説明

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

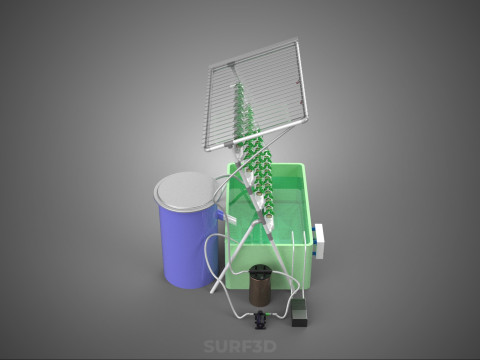

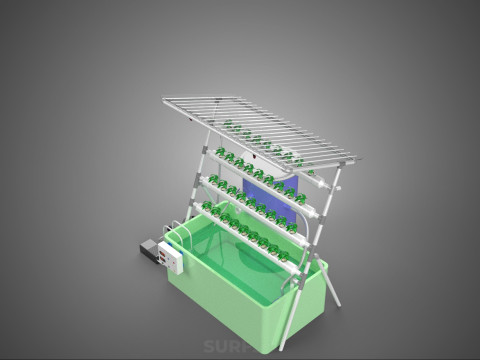

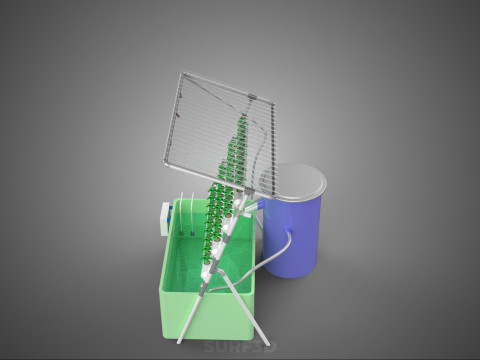

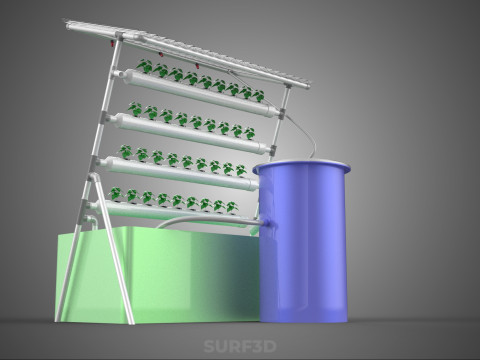

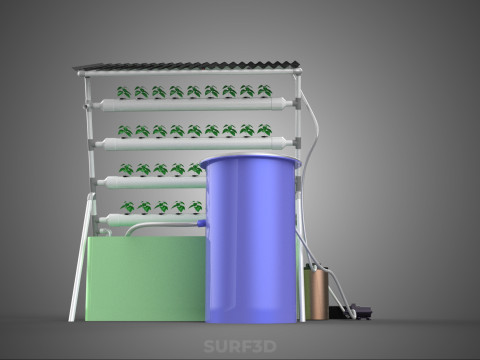

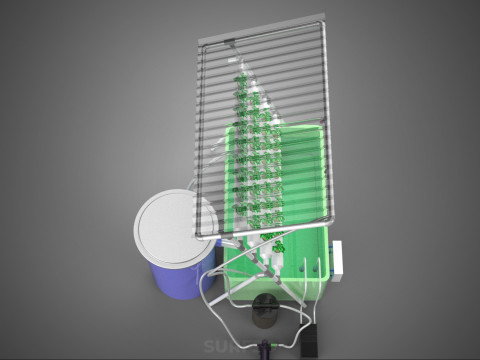

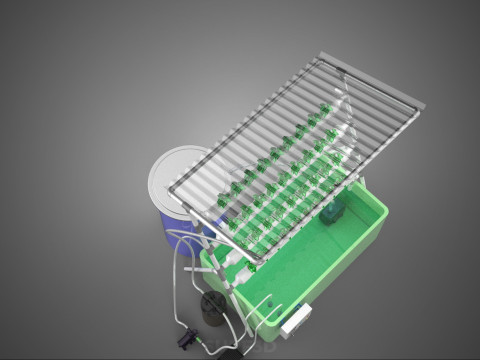

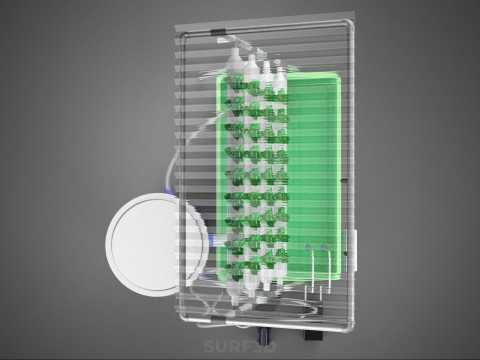

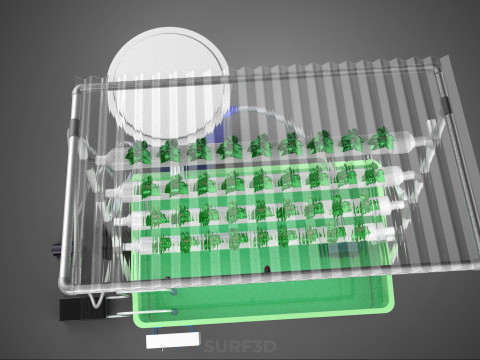

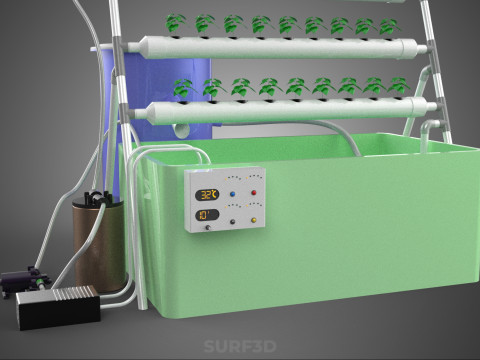

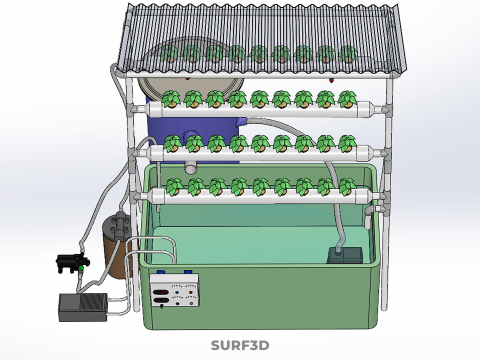

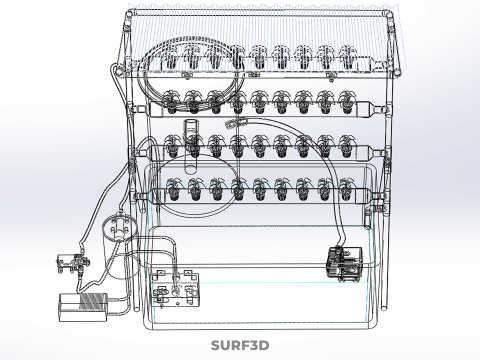

The "IoT Hydroponic Plant Auto Control Water Cycle Pump Nozzle Spray" system represents an advanced technological integration designed for the precise and automated management of plant cultivation within a hydroponic environment. This sophisticated framework leverages the Internet of Things (IoT) for remote monitoring and control, ensuring optimal plant growth conditions through a closed-loop water cycle, automated nutrient delivery, and atomized solution application via a pump and nozzle spray mechanism.

**Hydroponics and Automation Foundation:**

Hydroponics is a method of growing plants without soil, using mineral nutrient solutions dissolved in water. The precise delivery and management of these solutions are critical for plant health and productivity. Traditional hydroponic systems often require manual intervention for nutrient replenishment, pH adjustments, and water level monitoring. The introduction of "Auto Control" signifies the integration of intelligent systems that automate these processes, reducing labor and human error while optimizing environmental parameters.

**Internet of Things (IoT) Integration:**

At the core of this system is the Internet of Things (IoT), a network of interconnected physical devices embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet. In this context, IoT enables continuous, real-time data collection from various environmental sensors (e.g., pH, Electrical Conductivity (EC) for nutrient concentration, water level, temperature, humidity). This data is transmitted to a central control unit or a cloud-based platform, allowing for remote monitoring and the execution of control commands from virtually anywhere. This connectivity facilitates data-driven decision-making and predictive maintenance for the hydroponic setup.

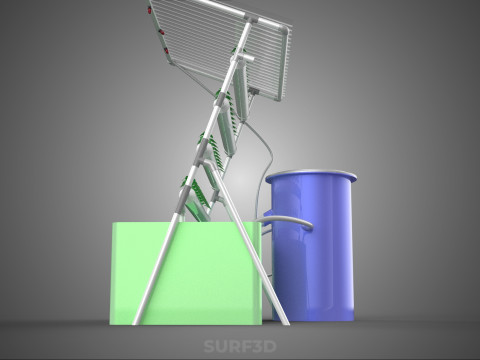

**Water Cycle and Nutrient Delivery:**

The "Water Cycle" component emphasizes the system's efficiency and sustainability. Rather than a one-time application, the nutrient solution is recirculated within a closed-loop system. After being delivered to the plants, any unused solution is collected and returned to a reservoir for filtration, replenishment, and reuse. This minimizes water waste, conserves nutrients, and reduces the environmental impact typically associated with traditional agriculture. The "Pump" is the critical actuator responsible for drawing the nutrient solution from the reservoir and propelling it through the delivery network to the plants.

**Nozzle Spray Mechanism:**

The "Nozzle Spray" aspect refers to the specific method of nutrient solution delivery. Unlike drip irrigation or flood-and-drain systems, a nozzle spray (often associated with aeroponics or certain hydroponic misting systems) atomizes the nutrient solution into a fine mist or tiny droplets. This method offers several advantages:

1. **Enhanced Oxygenation:** The fine mist provides excellent oxygenation to the root zone, which is crucial for root respiration and nutrient uptake.

2. **Efficient Nutrient Absorption:** The small droplet size increases the surface area for nutrient absorption by the roots.

3. **Uniform Distribution:** Properly designed spray nozzles ensure an even distribution of the nutrient solution across the root system.

4. **Reduced Pathogen Spread:** Compared to recirculating systems where roots are submerged, aeroponic spray systems can sometimes reduce the risk of root-borne diseases, provided proper hygiene.

**System Operation:**

The integrated system operates through a continuous feedback loop:

1. **Sensing:** Environmental sensors gather real-time data on parameters critical for plant growth (e.g., pH, EC, water level, root zone temperature).

2. **Data Transmission:** IoT modules transmit this data wirelessly to a microcontroller or a cloud server.

3. **Analysis and Decision-Making:** The control unit (e.g., Raspberry Pi, Arduino, or dedicated industrial controller) processes the data, comparing it against predefined optimal thresholds and plant-specific growth recipes.

4. **Actuation:** Based on the analysis, the control unit triggers actuators. For instance, if EC is low, a dosing pump may inject concentrated nutrient solution. If the water level is low, a water pump may refill the reservoir. Most critically, the primary pump is activated to deliver the nutrient solution via the nozzle spray system for a predetermined duration or at set intervals.

5. **Monitoring and Optimization:** Users can monitor system status and plant health remotely via a web interface or mobile application, and adjust parameters as needed, allowing for dynamic optimization of the growing conditions.

**Benefits and Applications:**

This IoT-driven automated hydroponic system offers significant benefits, including:

* **Resource Efficiency:** Substantial reduction in water and nutrient consumption.

* **Accelerated Growth and Yields:** Optimal and stable growing conditions lead to faster growth cycles and higher yields.

* **Reduced Labor:** Minimization of manual tasks related to monitoring and maintenance.

* **Improved Consistency and Quality:** Precise control ensures consistent environmental parameters, leading to uniform plant quality.

* **Remote Management:** Ability to manage and troubleshoot the system from any location.

* **Data-Driven Insights:** Collection of historical data for analysis and continuous improvement of cultivation strategies.

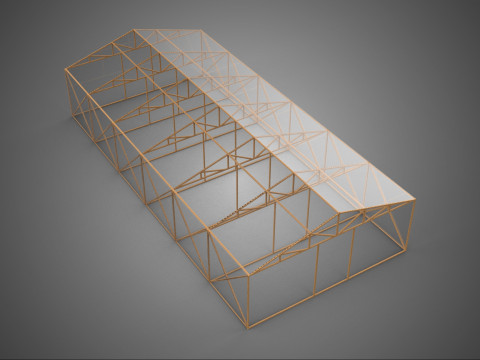

Applications span from commercial large-scale indoor farms and vertical farming operations to urban agriculture initiatives, research facilities, and hobbyist home growing setups, revolutionizing the way plants are cultivated in controlled environments.

フォーマットが必要ですか?

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. フリーフォーマット変換3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

使用情報

IOT水耕栽培プラント自動制御水循環ポンプノズルスプレー - このロイヤリティフリーの3Dモデルは、基本ライセンスまたは拡張ライセンスに従って、個人および商用目的で使用できます。基本ライセンスは、デジタル広告、デザインおよび視覚化プロジェクト、ビジネスソーシャルメディアアカウント、ネイティブアプリ、ウェブアプリ、ビデオゲーム、物理またはデジタル最終製品(無料および有償)など、ほとんどの標準的な使用事例をカバーしています。

拡張ライセンスには、基本ライセンスで付与されるすべての権利が使用制限なしで含まれており、ロイヤリティフリーの条件の下で、3Dモデルを無制限の商用プロジェクトで使用できます。

詳細を読む

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी