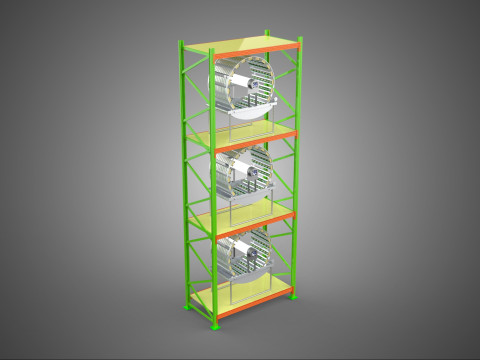

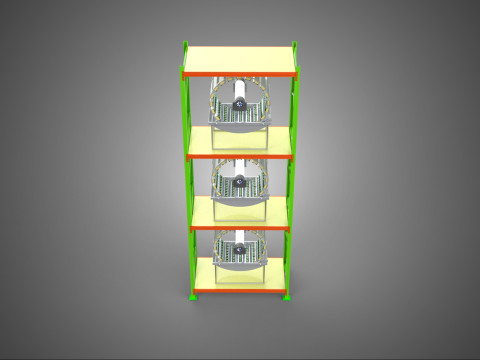

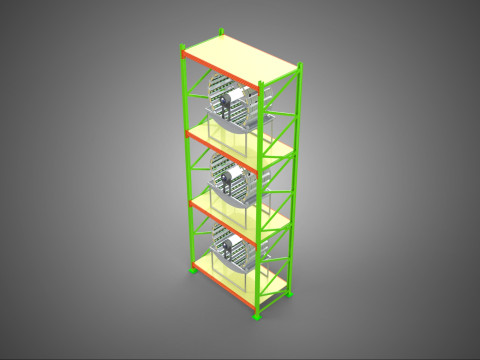

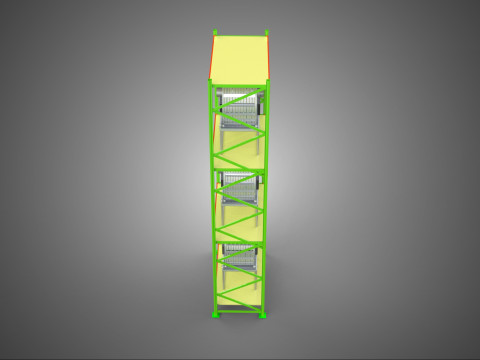

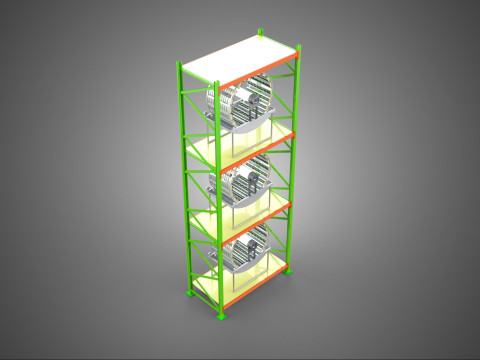

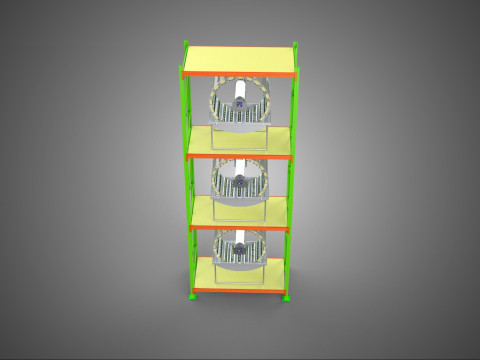

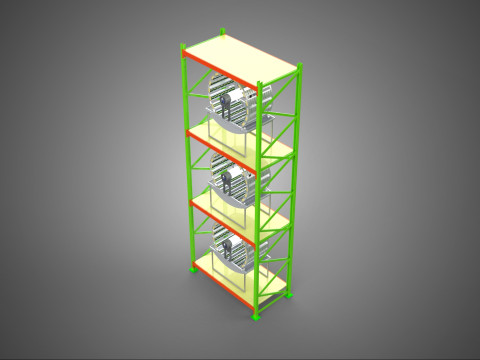

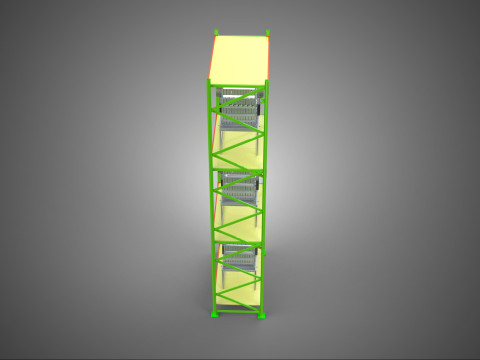

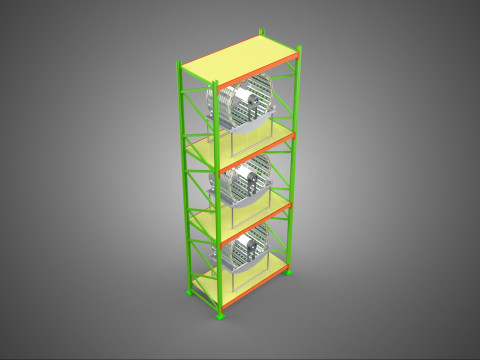

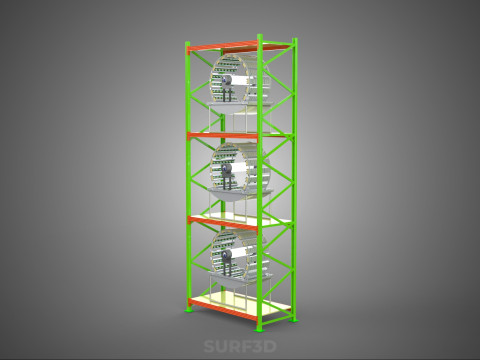

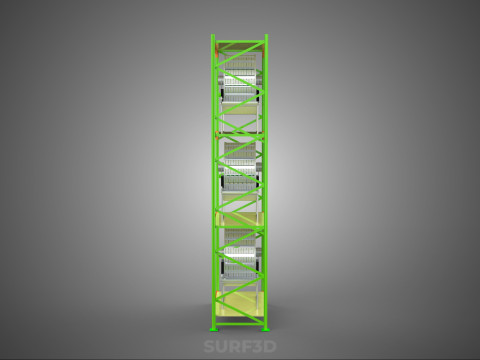

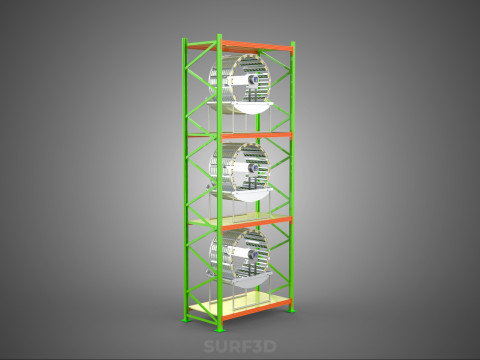

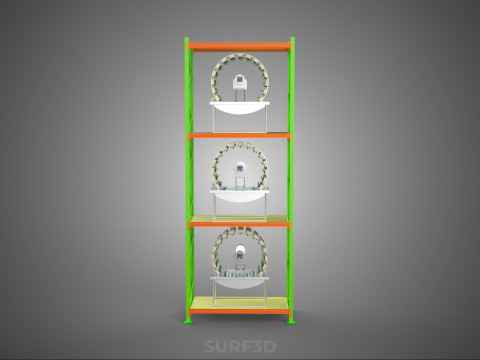

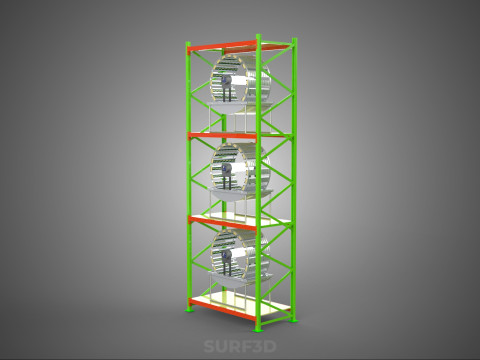

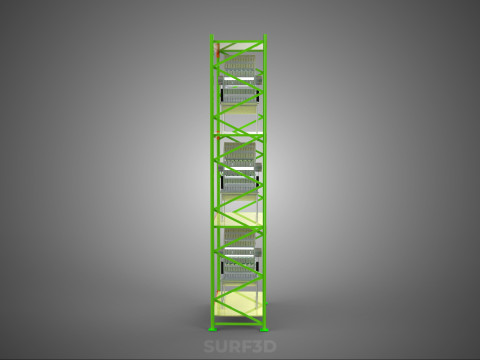

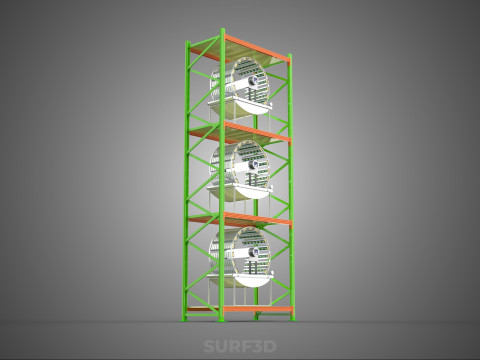

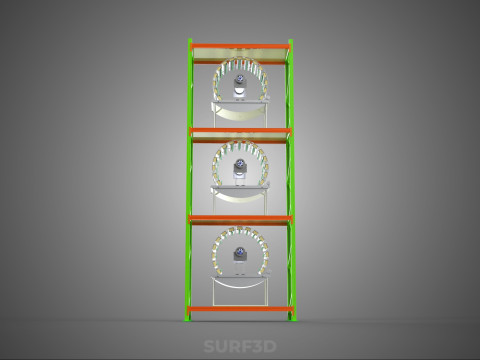

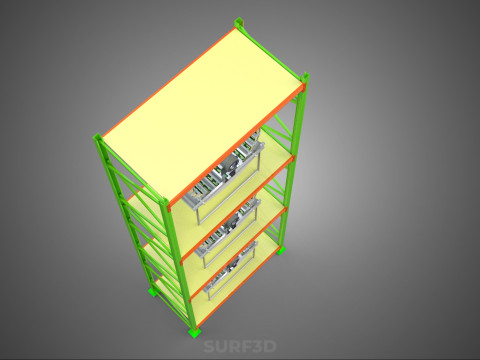

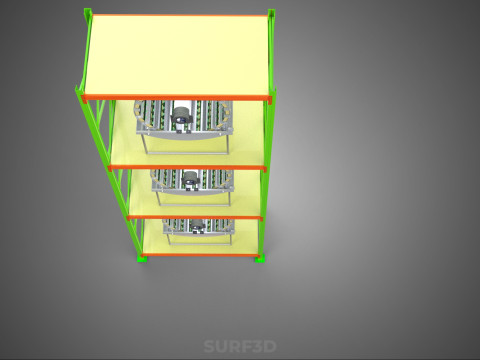

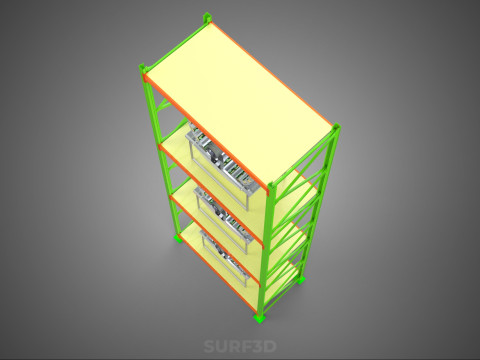

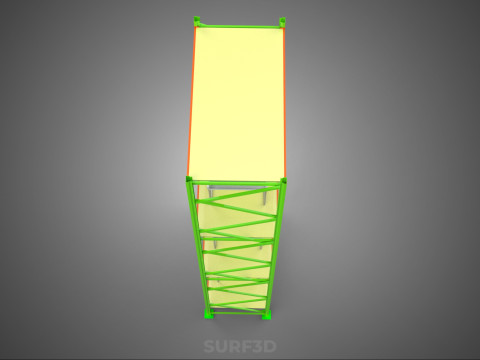

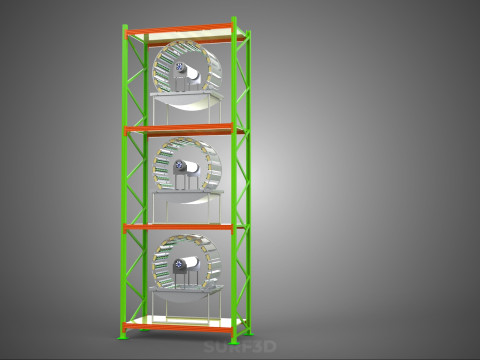

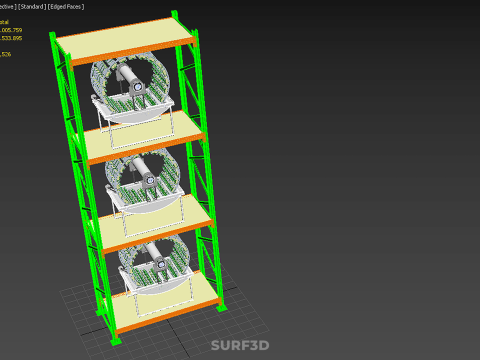

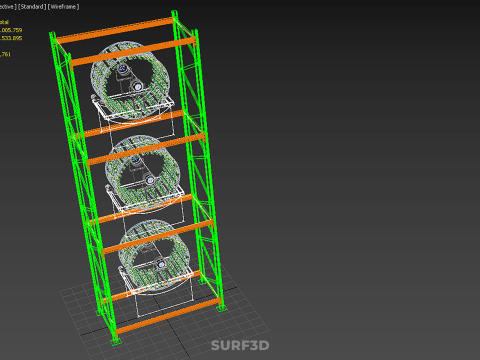

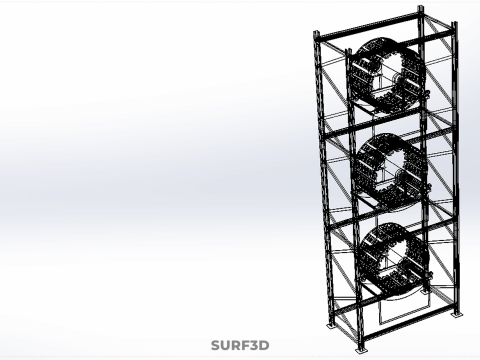

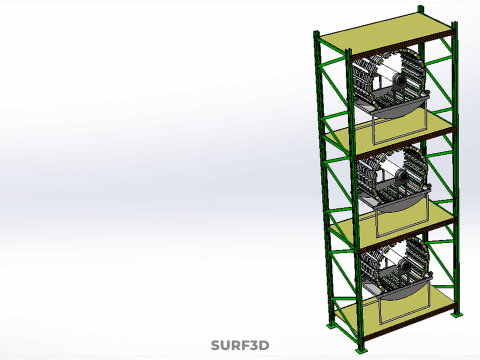

バーティカルガーデンタワー 回転式水耕栽培植物園 ライトグロー 3Dモデル

- 作者による製品サポートのリクエスト

- 利用可能フォーマット:

- アイテム ID:602683

- 日付: 2025-10-01

- 多角形:2005759

- 頂点:1533895

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:249

説明

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

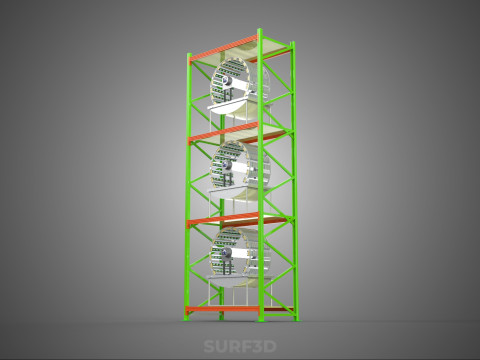

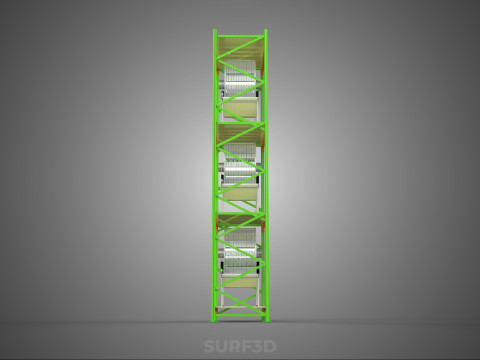

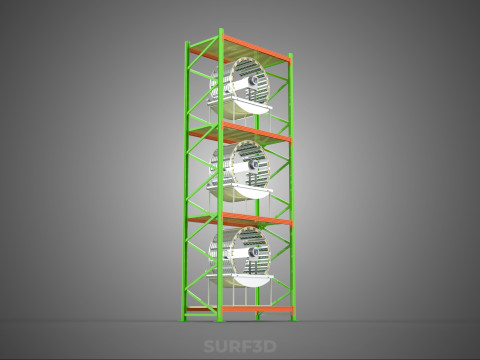

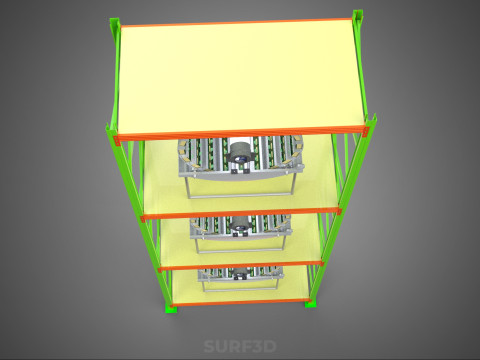

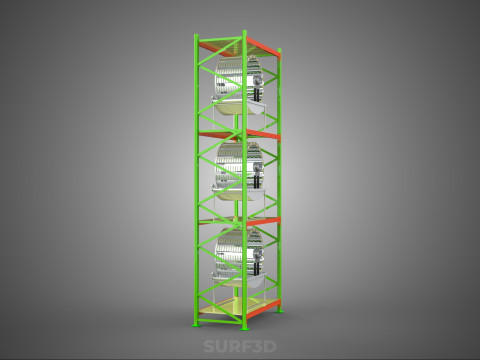

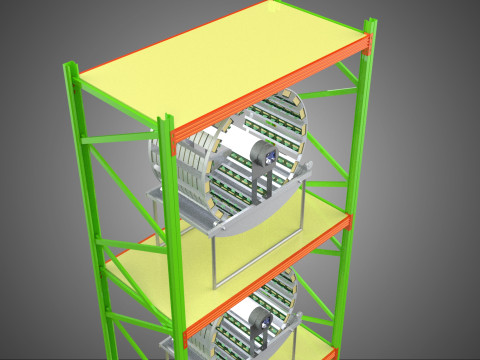

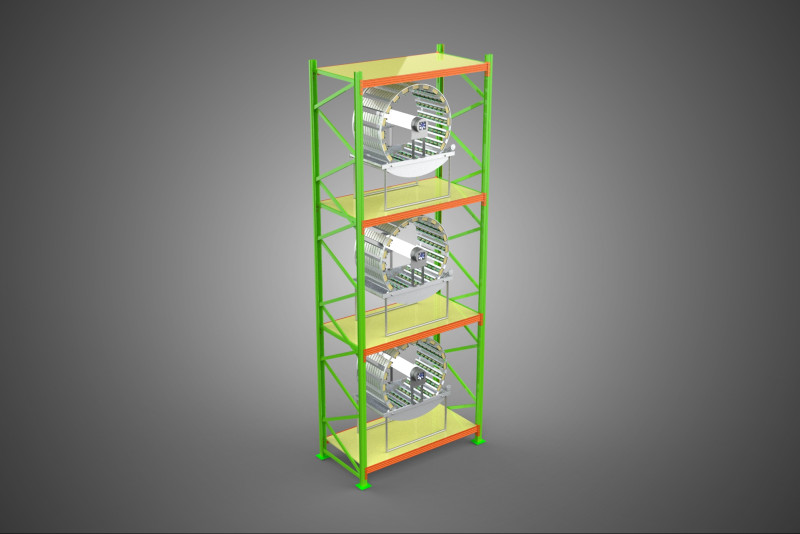

A **Vertical Garden Tower Rotary Hydroponic Plant Farm, with Integrated Light Growth System**, represents a sophisticated form of Controlled Environment Agriculture (CEA), integrating multiple advanced horticultural technologies to maximize plant production within minimal spatial footprints. This system is fundamentally a multi-tiered, vertically oriented cultivation apparatus that employs hydroponics for nutrient delivery, a rotary mechanism for optimizing environmental exposure, and artificial lighting to facilitate photosynthesis. It is engineered for intensive, soilless cultivation of various crops in environments where traditional agriculture is unfeasible or inefficient, often in urban or resource-constrained settings.

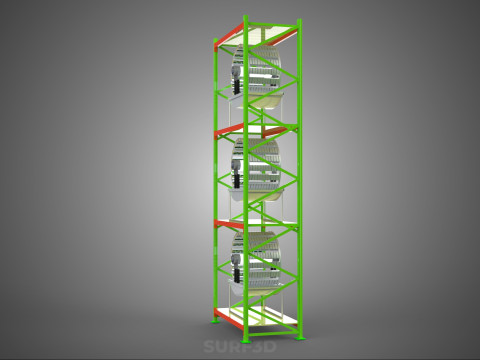

**System Architecture and Components:**

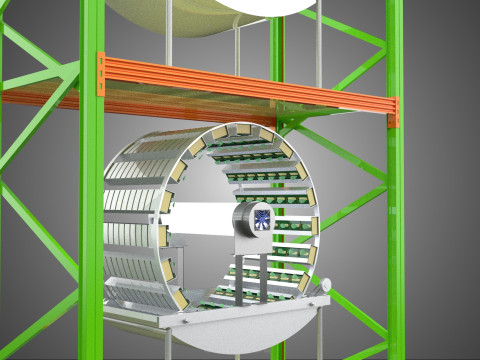

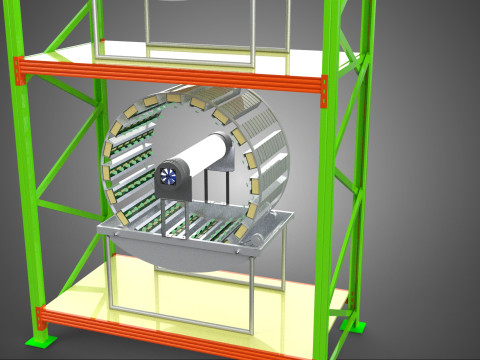

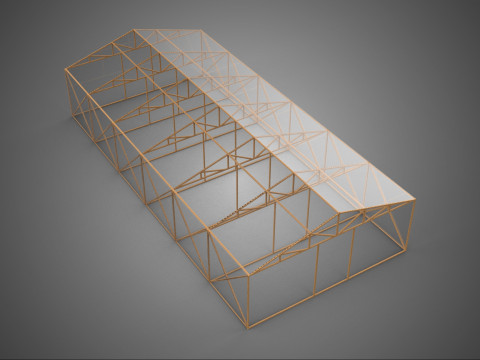

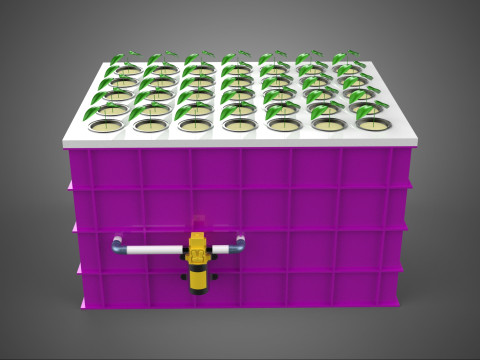

The core structure of such a system is a vertical tower, which can vary in height and diameter, typically housing multiple plant growth modules arranged concentrically around a central axis. These modules, often trays or pockets, hold individual plants or small clusters. The rotary mechanism, driven by an electric motor, allows the entire vertical array, or individual tiers, to slowly rotate. This rotation can be continuous or intermittent, serving to equalize light exposure for all plants, particularly those at the periphery or varying vertical positions, ensuring uniform growth and development.

The hydroponic component eliminates the need for soil, supplying a precisely balanced nutrient solution directly to plant roots. Common hydroponic methods integrated into these systems include Nutrient Film Technique (NFT), Deep Water Culture (DWC), or wick systems, though specialized approaches tailored for vertical and rotary integration are prevalent. The nutrient solution is typically recirculated from a reservoir, passing through the plant modules, and often includes filtration and aeration to maintain optimal conditions.

Artificial lighting, primarily utilizing Light Emitting Diodes (LEDs), is central to the "Light Grow" aspect. These LED arrays are strategically positioned, often centrally within the tower or externally, to provide the necessary photosynthetically active radiation (PAR) spectrum and intensity. LEDs are favored for their energy efficiency, tunable spectral output (allowing optimization for specific growth stages or plant types), and reduced heat emission compared to traditional grow lights, which minimizes additional cooling requirements.

**Operational Principles:**

Operationally, the system aims to create an optimal microclimate for plant growth. Plants are anchored in inert growing media (e.g., rockwool, coco coir, clay pebbles) within the modules. The nutrient solution is pumped from a reservoir, irrigating the roots, and then returned, minimizing water waste. The slow rotation of the plant modules around the central light source ensures that all plants receive equitable and consistent exposure to the artificial light, preventing etiolation or uneven development. This continuous movement also assists in uniform airflow around the plants, reducing the risk of fungal diseases and promoting healthy transpiration. Sophisticated control systems often monitor and adjust environmental parameters such as temperature, humidity, CO2 levels, nutrient solution pH, and electrical conductivity (EC), as well as light intensity and photoperiod, automating the cultivation process.

**Key Advantages:**

The advantages of a Vertical Garden Tower Rotary Hydroponic Plant Farm are substantial:

1. **Space Efficiency:** Maximizes crop production per unit area, making it ideal for urban environments or locations with limited arable land.

2. **Water Conservation:** Hydroponic systems, especially recirculating ones, can reduce water consumption by up to 90-95% compared to traditional field farming.

3. **Accelerated Growth and Higher Yields:** Controlled environmental conditions, optimized nutrient delivery, and consistent lighting often lead to faster growth cycles and greater biomass production.

4. **Year-Round Production:** Indoor cultivation negates seasonal limitations and adverse weather conditions.

5. **Reduced Pest and Disease Pressure:** The controlled, often semi-closed, environment significantly lowers the incidence of pests and pathogens, minimizing or eliminating the need for pesticides.

6. **Localized Food Production:** Enables food cultivation near consumption centers, reducing transportation costs, carbon footprint, and enhancing food freshness and security.

7. **No Soil Degradation:** Eliminates issues associated with soil erosion, nutrient depletion, and soil-borne diseases.

**Challenges and Considerations:**

Despite its benefits, the implementation of such systems presents challenges:

1. **High Initial Investment:** Setup costs for advanced equipment, automation, and infrastructure can be substantial.

2. **Energy Consumption:** While LEDs are efficient, the cumulative energy demand for lighting, climate control (HVAC), pumps, and automation can be significant.

3. **Technical Expertise:** Requires specialized knowledge in hydroponics, plant physiology, environmental control, and system maintenance.

4. **System Complexity:** Interdependency of components means a failure in one area can impact the entire farm.

5. **Limited Crop Diversity:** Most economically viable for high-value, fast-growing crops like leafy greens, herbs, and some small fruits; less suitable for staple crops or large root vegetables.

**Applications and Impact:**

These systems are primarily deployed in urban vertical farms, research facilities, educational institutions, and regions with challenging agricultural climates or limited access to fresh produce. They are pivotal in advancing sustainable agriculture, addressing food security concerns, and supporting the "local food" movement. Continued innovation focuses on improving energy efficiency, reducing operational costs, and integrating artificial intelligence and machine learning for predictive analytics and further automation.

フォーマットが必要ですか?

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. フリーフォーマット変換3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

使用情報

バーティカルガーデンタワー 回転式水耕栽培植物園 ライトグロー - このロイヤリティフリーの3Dモデルは、基本ライセンスまたは拡張ライセンスに従って、個人および商用目的で使用できます。基本ライセンスは、デジタル広告、デザインおよび視覚化プロジェクト、ビジネスソーシャルメディアアカウント、ネイティブアプリ、ウェブアプリ、ビデオゲーム、物理またはデジタル最終製品(無料および有償)など、ほとんどの標準的な使用事例をカバーしています。

拡張ライセンスには、基本ライセンスで付与されるすべての権利が使用制限なしで含まれており、ロイヤリティフリーの条件の下で、3Dモデルを無制限の商用プロジェクトで使用できます。

詳細を読む

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी