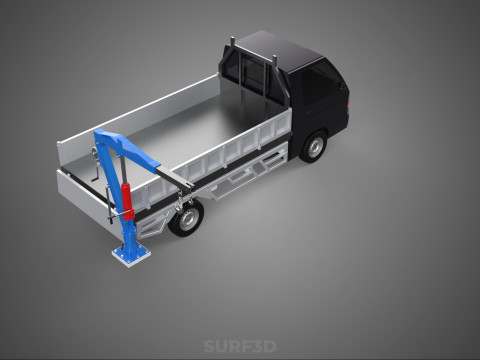

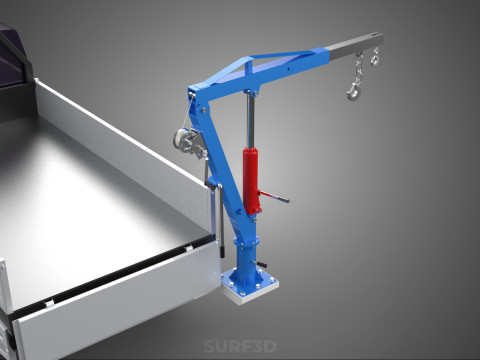

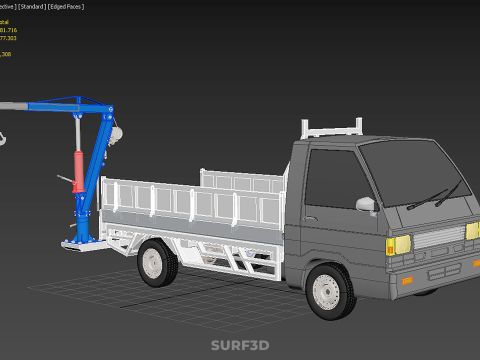

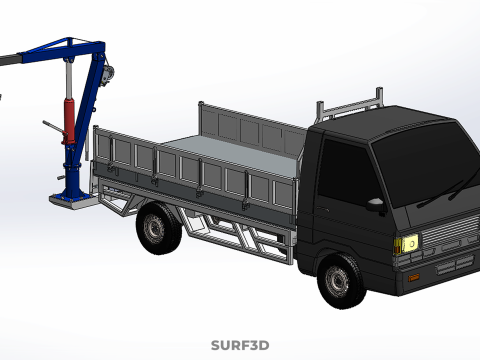

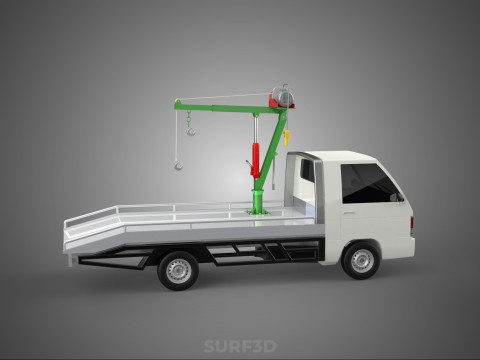

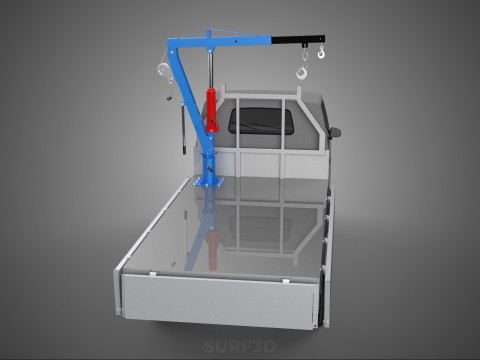

FOLDABLE MOUNTED BED CRANE HOIST LIFTING HAND WINCH TRUCK PICKUP 3Dモデル

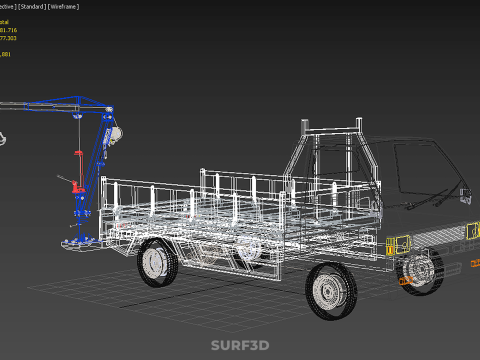

- 利用可能フォーマット: Rhinoceros (.3dm) 46.42 MB3D Studio (.3ds) 5.79 MBBlender3D (.blend) 15.65 MBCollada (.dae) 15.37 MBAutodesk AutoCAD (.dwg) 22.69 MBAutodesk FBX (.fbx) 20.28 MBGLB (.glb / .gltf) 7.56 MBIGES (.iges) 10.90 MBAutodesk 3DS MAX (.max) 33.63 MBWavefront OBJ (.obj) 11.72 MBACIS(.sat) 21.43 MBSketchUp (.skp) 15.93 MBSTEP (.step) 13.39 MBStereolithography (.stl) 12.09 MB

- 多角形:881716

- 頂点:677303

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:142

- 日付: 2025-08-21

- アイテム ID:593432

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

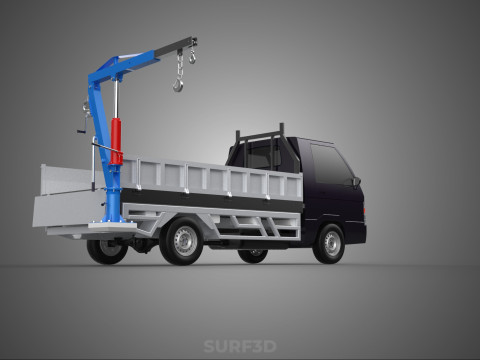

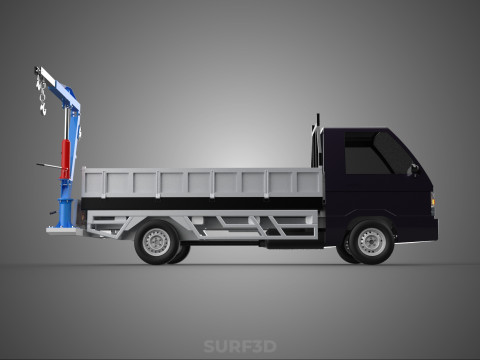

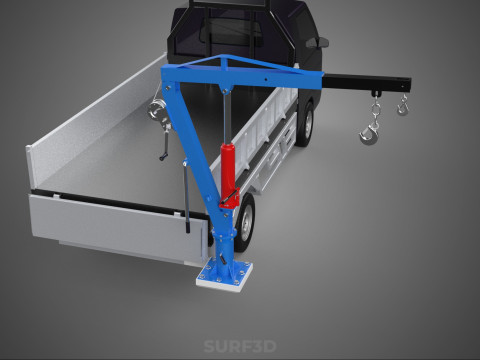

A "Foldable Mounted Bed Crane Hoist Lifting Hand Winch Truck Pickup" refers to a specialized, self-contained material handling apparatus designed for installation onto the cargo bed of a pickup truck or similar utility vehicle. Its primary purpose is to provide a portable and independent means for the manual lifting, loading, and unloading of heavy, bulky, or ******* objects, thereby mitigating the need for external lifting equipment, powered machinery, or extensive manual labor.

**Nomenclature and Function:**

This device is characterized by several key functional descriptors:

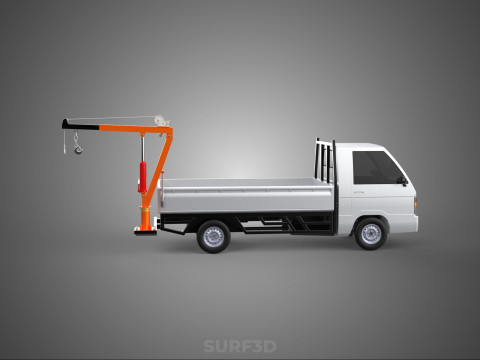

* **Foldable:** Indicates that the boom or main lifting arm can be collapsed, pivoted, or stowed into a compact configuration when not in use. This feature optimizes space within the truck bed, allowing the vehicle to retain significant cargo capacity and reducing the overall profile for travel or storage.

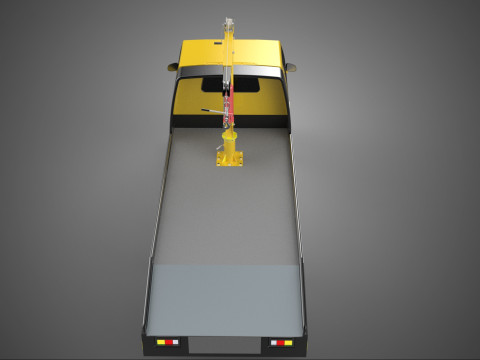

* **Mounted Bed:** Signifies its direct and secure attachment to the bed, typically through robust bolts or clamps, ensuring stability and integration with the vehicle.

* **Crane Hoist:** Refers to the overarching mechanism. A "crane" implies a boom-based lifting structure, while a "hoist" is the specific component (often a winch and cable system) that performs the vertical movement of the load.

* **Lifting:** The fundamental operation of raising objects from a lower to a higher position.

* **Hand Winch:** Denotes the manual power source for the hoist. It operates via a crank handle, gears, and a drum, providing mechanical advantage to lift loads without reliance on electrical, hydraulic, or pneumatic power systems.

* **Truck Pickup:** Specifies the target vehicle type, indicating its suitability for light-duty commercial or personal utility trucks.

**Design and Components:**

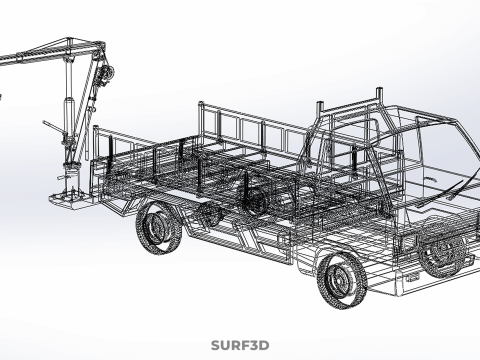

Typically constructed from high-strength steel with a durable, often powder-coated or galvanized finish for corrosion resistance, the apparatus comprises:

1. **Mounting Base:** A sturdy steel plate or frame engineered for secure attachment to the truck bed, serving as the stable anchor point.

2. **Boom Arm:** A telescopic or articulated arm that extends horizontally and vertically. The "foldable" aspect is achieved through pivot points, pins, and locking mechanisms that allow the arm to be quickly deployed for use and then compactly stowed.

3. **Hand Winch Assembly:** Integrated into the crane structure, this includes a robust manual crank, a gear reduction system, a cable drum, and a steel cable or high-strength synthetic rope. Most units feature a load-holding brake (e.g., a ratchet or automatic brake) to secure the load at any height and prevent uncontrolled descent.

4. **Pulley/Sheave System:** Located at the end of the boom, this guides the lifting cable, reducing friction and facilitating smooth operation.

5. **Load Hook:** A secure hook, often with a safety latch, attached to the end of the lifting cable for connecting to the load.

6. **Slewing Mechanism (Optional but Common):** Many models incorporate a swivel base or pivot point that allows the boom to rotate horizontally (slew) over a defined arc (e.g., 90°, 180°, or 360° with stops), enabling precise positioning of the load into or out of the truck bed. This mechanism is typically manually operated and lockable.

**Operational Mechanism:**

To operate, the foldable boom is extended and secured in its working position. The load is then attached to the hook. The hand winch is cranked, engaging the gears to reel in the cable, thereby lifting the load. The built-in braking system automatically holds the load when the cranking action stops. To lower the load, the brake is released or the winch is cranked in reverse in a controlled manner. Once lifting operations are complete, the boom can be quickly folded and secured, minimizing its footprint and preparing the truck for transport.

**Key Features and Advantages:**

The design offers several distinct benefits:

* **Versatility and Mobility:** Mounted on a pickup truck, it provides mobile lifting capabilities, enabling heavy lifting operations wherever the truck can access.

* **Power Independence:** The manual hand winch eliminates the need for external power sources, making it ideal for remote job sites, off-grid applications, or emergency situations where electricity or hydraulics are unavailable.

* **Space Optimization:** The foldable design is paramount, ensuring the crane does not permanently consume significant truck bed space, preserving cargo capacity when not in use.

* **Cost-Effectiveness:** Generally more affordable than powered or larger fixed lifting solutions, both in initial purchase and ongoing maintenance.

* **Durability:** Built for rigorous use, these units are designed to withstand challenging outdoor and industrial environments.

**Applications:**

This type of lifting apparatus is widely utilized across various sectors, including:

* **Construction:** Loading and unloading building materials, tools, or compact equipment.

* **Agriculture:** Handling feed sacks, farm implements, or produce.

* **Utility and Field Service:** Lifting generators, pumps, air compressors, or other heavy service equipment.

* **Landscaping:** Maneuvering heavy rocks, trees, or bags of soil.

* **Recreational:** Assisting with the loading of ATVs, motorcycles, hunting gear, or heavy coolers.

* **Emergency Services:** Facilitating the handling of heavy rescue equipment or supplies.

**Safety and Specifications:**

Safe operation is paramount and hinges on several factors, including strict adherence to the manufacturer's **Working Load Limit (WLL)** or **Safe Working Load (SWL)**. It is crucial to ensure that the truck's cargo bed and suspension system are capable of supporting the combined weight of the crane and its maximum load. Proper installation, stable vehicle positioning (e.g., on level ground, with potential use of vehicle stabilizers if available), and user training in correct operating procedures and maintenance are essential to prevent accidents and ensure long-term functionality.

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी