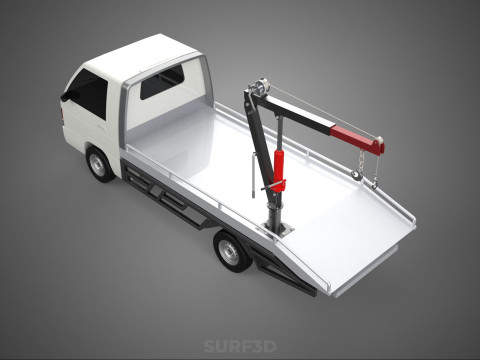

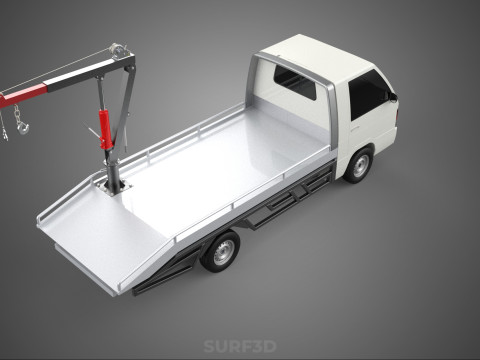

CRANE LIFTING SWIVEL WINCH HOIST JIB HOOK FLATBED TRUCK PICKUP 3Dモデル

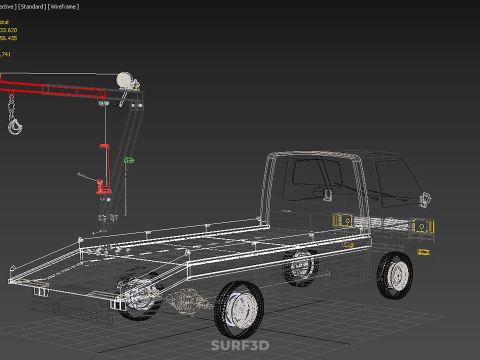

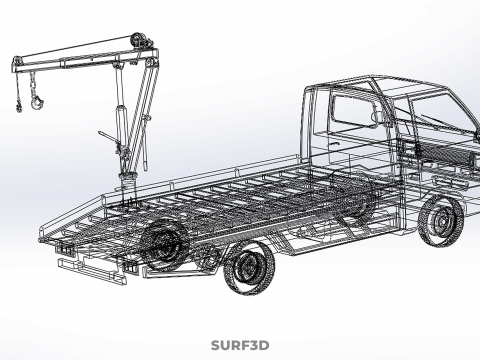

- 利用可能フォーマット: Blender3D (.blend) 13.00 MBGLB (.glb / .gltf) 6.25 MBCollada (.dae) 12.78 MBStereolithography (.stl) 10.19 MBACIS(.sat) 15.47 MBAutodesk FBX (.fbx) 16.66 MBWavefront OBJ (.obj) 9.89 MBIGES (.iges) 7.99 MBSTEP (.step) 7.62 MBRhinoceros (.3dm) 31.03 MBAutodesk AutoCAD (.dwg) 18.68 MB3D Studio (.3ds) 4.79 MBSketchUp (.skp) 11.92 MBAutodesk 3DS MAX (.max) 27.09 MB

- 多角形:733620

- 頂点:556435

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:198

- 日付: 2025-08-12

- アイテム ID:592212

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.***) – Provided for Rhino users

Model Info

• - All files are checked and ****ed for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

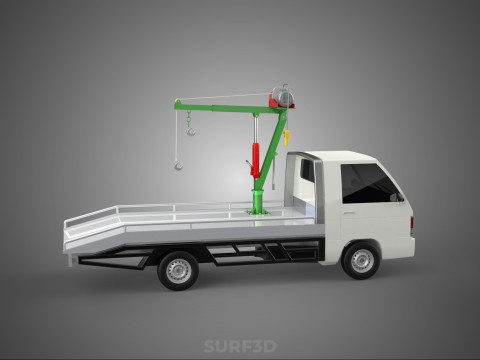

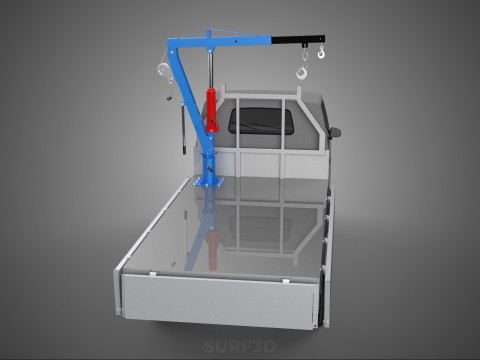

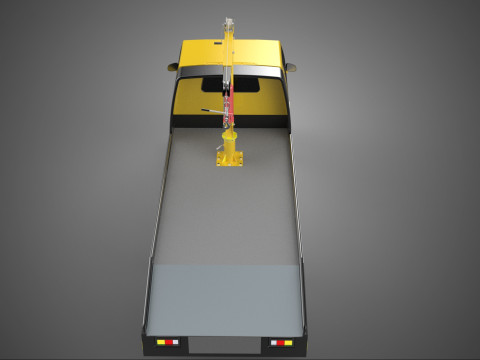

A **truck-mounted crane system**, often referred to as a service crane, utility crane, or mobile crane, is a specialized piece of heavy equipment designed for the efficient lifting, lowering, and precise positioning of materials and equipment on various job sites. This system integrates a complete lifting apparatus—comprising a jib (boom), ***ch, hoist, and hook—onto the chassis of a light- to medium-duty commercial vehicle, most commonly a flatbed truck or pickup truck. This configuration provides exceptional mobility and versatility, bridging the gap ***ween manual handling and larger, dedicated mobile cranes.

### Components and Structure:

1. **Vehicle Platform:** The foundational element is a robust flatbed truck or pickup truck. These vehicles are chosen for their maneuverability, on-road capabilities, and the inherent strength of their chassis, which is often reinforced to support the crane's weight and the dynamic forces generated during lifting operations. The specific vehicle chosen depends on the required lifting capacity and operational environment.

2. **Mounting Pedestal/Mast:** This is the primary structural component that securely anchors the entire crane assembly to the vehicle's frame, typically located behind the cabin or at the rear of the flatbed. It provides the stable base and pivot point for the crane's rotational movement.

3. **Jib/Boom:** Also known as the boom, this is the extendable or articulating arm that projects from the mast. It can be:

* **Telescopic Boom:** Consisting of several sections that extend and retract linearly, offering straightforward reach.

* **Articulating (******* Boom) Jib:** Features multiple hinged sections, similar to a human arm, allo***g for greater maneuverability, the ability to reach around obstacles, and compact stowage. The term "swivel" in the prompt primarily refers to the crane's rotational capability, but articulating jibs also allow for "swivel" at their joints.

4. **Sle***g/Swivel Mechanism:** Integrated within the mast or pedestal, this mechanism enables the jib and its suspended load to rotate horizontally. Depending on the design, this rotation can be continuous (360 degrees) or limited to a specific arc, allo***g the operator to move loads across a wide working area without repositioning the vehicle.

5. *****ch and Hoist System:** The ***ch is a motor-driven drum around which a high-strength wire rope (cable) is spooled. The hoist mechanism, often integrated with the ***ch, provides the vertical lifting and lowering power by controlling the ***ding and un***ding of the cable. Power for the hoist typically comes from the vehicle's engine, often via a hydraulic pump (for hydraulic systems) or directly from the electrical system (for electric ***ches, usually on smaller units).

6. **Hook:** The terminal lifting attachment connected to the end of the wire rope. It is typically forged from high-strength steel and equipped with a safety latch to prevent accidental disengagement of the load.

7. **Hydraulic System:** Most modern truck-mounted cranes are hydraulically powered. This system consists of a pump, reservoir, control valves, and hydraulic cylinders that precisely control the extension, retraction, articulation, sle***g, and hoisting functions.

8. **Outriggers/Stabilizers:** These are extendable support legs deployed from the vehicle chassis before lifting operations begin. They serve to increase the effective base of support, distribute the load more evenly, and prevent the truck from tipping or becoming unstable, particularly when lifting heavy loads or operating on uneven terrain.

### Functionality and Operation:

Operation typically begins with positioning the vehicle on a stable, level surface and deploying the outriggers to ensure maximum stability. The operator then extends the jib to the desired reach and height, lowers the hoist cable, attaches the hook to the load, and commences the lift. Loads can then be slewed (rotated) to their intended placement. Control systems vary from direct manual levers on the crane itself to wired remote pendants or advanced wireless radio remote controls, offering the operator improved visibility and safety during operation. Load charts and safety indicators are critical for ensuring that the crane's operational limits are not exceeded.

### Applications:

Truck-mounted crane systems are indispensable in a wide array of industries due to their mobility and versatility. Common applications include:

* **Construction:** Lifting and placing building materials, tools, and small machinery on construction sites.

* **Utility Services:** Installing and maintaining power poles, transformers, streetlights, and other infrastructure.

* **Landscaping:** Moving large rocks, trees, pavers, and other heavy landscaping elements.

* **Roadside Assistance and Vehicle Recovery:** Lifting engines, machinery, or aiding in minor vehicle recovery scenarios.

* **Logistics and Delivery:** Loading and unloading heavy, bulky items at delivery points where dedicated lifting equipment is unavailable.

* **Municipal Services:** Sign installation, storm drain maintenance, and other public works tasks.

### Advantages and Considerations:

The primary advantages of these systems are their exceptional mobility, rapid deployment, ability to access confined spaces, and the reduction of manual labor, which enhances safety and efficiency. However, their lifting capacities are inherently limited compared to larger, dedicated mobile cranes, and safe operation mandates adherence to load charts, proper outrigger deployment, and operation on stable ground. Operator training and certification are crucial due to the inherent risks associated with lifting heavy loads.

KEYWORDS: Truck-mounted crane, Service crane, Utility crane, Mobile crane, Lifting equipment, Material handling, Flatbed truck, Pickup truck, Jib crane, Boom crane, Articulating boom, ******* boom, Telescopic boom, ***ch, Hoist, Crane hook, Outriggers, Stabilizers, Hydraulic system, Sle***g mechanism, Load capacity, On-site lifting, Construction equipment, Utility services, Material transport, Portable crane, Lifting safety, Remote control, Chassis mounted, Mobile lifting solution

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी