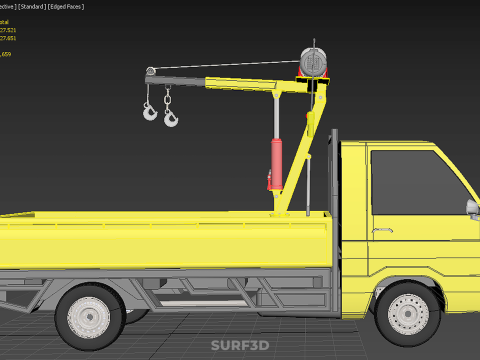

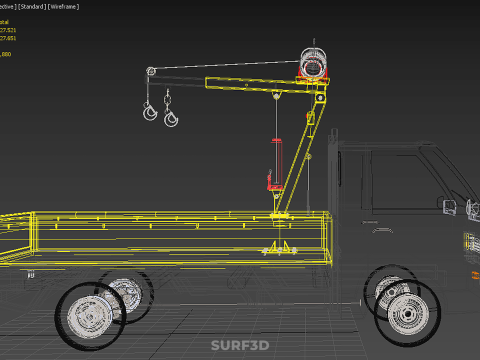

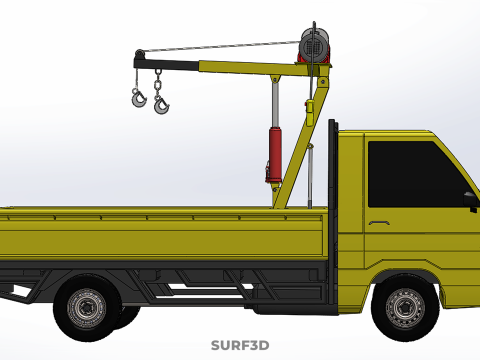

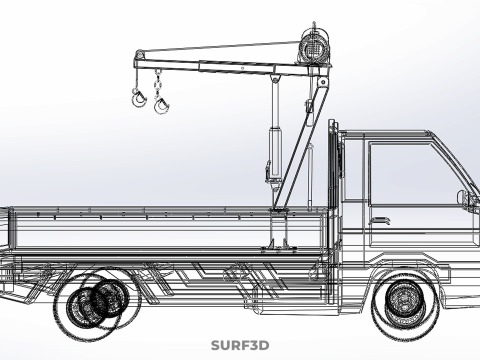

SMALL MINI COMPACT PICKUP TRUCK WINCH HOIST HYDRAULIC CRANE JIB 3Dモデル

- 利用可能フォーマット: Blender3D (.blend) 9.89 MBAutodesk AutoCAD (.dwg) 18.76 MBCollada (.dae) 10.96 MBACIS(.sat) 15.47 MBRhinoceros (.3dm) 27.68 MBAutodesk FBX (.fbx) 12.77 MBSTEP (.step) 7.57 MBSketchUp (.skp) 9.18 MBIGES (.iges) 7.19 MBWavefront OBJ (.obj) 7.66 MBAutodesk 3DS MAX (.max) 24.30 MBGLB (.glb / .gltf) 5.27 MBStereolithography (.stl) 8.18 MB3D Studio (.3ds) 3.89 MB

- 多角形:527521

- 頂点:427651

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:177

- 日付: 2025-08-16

- アイテム ID:592851

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

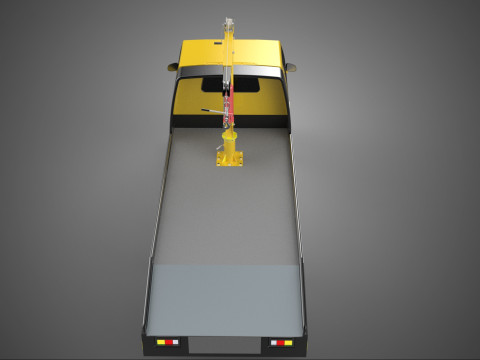

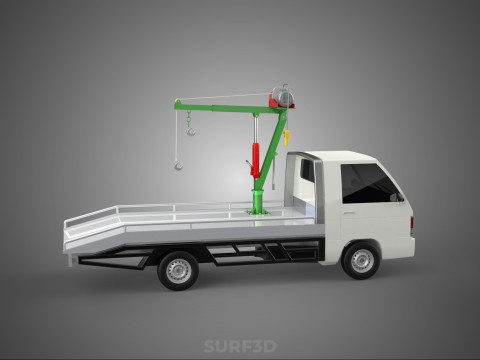

A **Small Mini Compact Pickup Truck with Electric ***ch Hoist Hydraulic Crane Jib** describes a highly specialized utility vehicle designed for precision material handling and transportation within confined or challenging environments where larger equipment is impractical. This configuration integrates a compact, light-duty pickup truck chassis with advanced lifting and pulling capabilities, specifically a hydraulically operated crane jib complemented by an electrically powered ***ch or hoist mechanism. The amalgamation transforms a standard light-duty vehicle into a versatile mobile lifting and pulling platform, optimized for maneuverability and efficiency.

The base vehicle, characterized as "small," "mini," and "compact," typically refers to pickup trucks with significantly reduced dimensions compared to full-size counterparts. This category may include Kei trucks (Japanese mini trucks), older compact pickups, or modern unibody compact trucks. Their defining attributes include superior maneuverability, a smaller turning radius, lower operational costs, and the crucial ability to access tight urban environments, narrow industrial aisles, or rugged off-road paths unsuitable for larger vehicles. Payload capacities are generally modest, typically ranging from a few hundred kilograms to approximately one metric ton, rendering them ideal for light to medium-duty tasks.

The core of this specialized vehicle's functionality lies in its integrated lifting system:

The **Hydraulic Crane Jib** serves as the primary lifting apparatus. It comprises a robust, often telescopic, boom mounted strategically on the truck chassis, commonly behind the cab, at the rear of the bed, or occasionally on a custom subframe. Hydraulic power, typically derived from the truck's engine via a Power Take-Off (PTO) or an independent electric pump, actuates the crane's movements. These movements usually include:

* **Sle***g (Rotation):** Allo***g the jib to pivot horizontally, providing a wide working radius.

* **Luffing (Elevation):** Changing the angle of the boom to control lift height.

* **Telescoping (Extension):** Extending or retracting the boom to adjust reach.

Hydraulic systems facilitate precise control, smooth operation, and substantial lifting power relative to their size, enabling accurate manipulation of objects. Lifting capacities for such cranes on compact trucks are optimized for vehicle stability and chassis strength, typically ranging from 500 kg to 2,000 kg (approximately 1,100 lbs to 4,400 lbs) at reduced radii. For stability during lifting operations, these vehicles are frequently equipped with manually or hydraulically deployable outriggers (stabilizer legs) to prevent tipping.

The **Electric ***ch Hoist** complements the hydraulic crane, providing additional or alternative lifting and pulling capabilities. It is commonly mounted either directly on the crane's jib (as an integrated hoist drum) or as an independent unit on the truck's chassis, often at the front or rear. Powered by the vehicle's electrical system (typically 12V or 24V DC), an electric motor drives a drum that ***ds or un***ds a steel cable or synthetic rope. As a **hoist**, it facilitates vertical lifting, often for lighter loads or precise positioning after the main hydraulic lift. As a *****ch**, it provides pulling force for dragging objects, vehicle recovery, or tensioning applications. Its advantages include ease of use, instant power availability (even without the engine running, though battery drain is a consideration), and relatively low maintenance. Capacities vary widely, but common configurations range from 1,000 lbs to 10,000 lbs (approximately 450 kg to 4,500 kg) for pulling applications, with vertical hoisting capacities generally lower.

This specialized vehicle configuration finds utility across a diverse range of sectors where agility, precision, and lifting capability are paramount within constricted environments. Primary applications include: utility services (e.g., power line, telecommunications, street light maintenance), light construction, landscaping and arboriculture (e.g., lifting trees, logs, rocks), municipal operations (e.g., park maintenance, public works), light industrial and commercial use (e.g., loading/unloading goods, equipment installation), and limited emergency services.

The primary advantages of this vehicle type include its unparalleled maneuverability for accessing tight urban streets, narrow alleys, indoor facilities, or challenging off-road terrains; its versatility, combining transportation, lifting, and pulling functions in a single, compact unit; and its cost-effectiveness compared to larger, dedicated crane trucks or separate pieces of equipment. It also contributes to increased efficiency, reduced manual labor, enhanced safety, and a smaller operational footprint.

Safe operation necessitates strict adherence to manufacturer guidelines, particularly regarding load charts, stability limits, and the proper deployment of outriggers. Operator training is crucial to prevent rollovers or overloading. The vehicle's electrical system must be robust enough to support the ***ch/hoist's power demands, especially during prolonged use. Regular maintenance of both the vehicle and the integrated lifting systems is essential for reliability and longevity.

In conclusion, the Small Mini Compact Pickup Truck with Electric ***ch Hoist Hydraulic Crane Jib represents an engineered solution for specialized material handling challenges. By integrating a highly adaptable lifting system onto a nimble vehicle platform, it offers an optimal balance of accessibility, power, and efficiency for tasks requiring precise lifting and pulling within constrained or difficult-to-reach environments.

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी