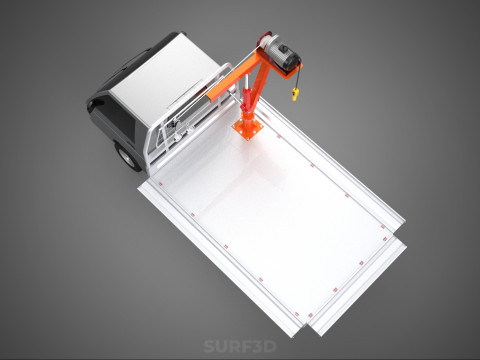

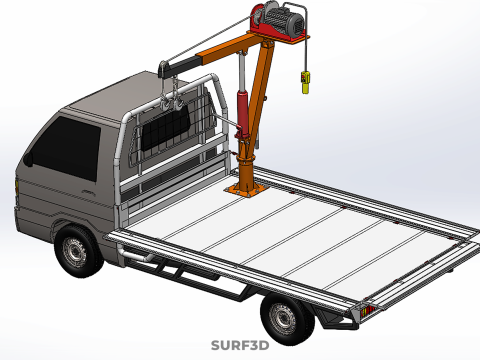

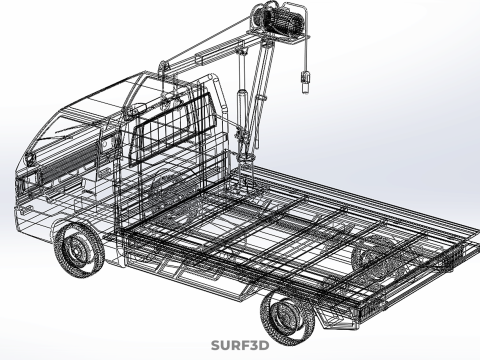

ワイドデッキ ジブ クレーン リフト ホイスト モーター ウインチ フック トラック ピックアップ カー 3Dモデル

- 作者による製品サポートのリクエスト

- 利用可能フォーマット:

- アイテム ID:594370

- 日付: 2025-08-23

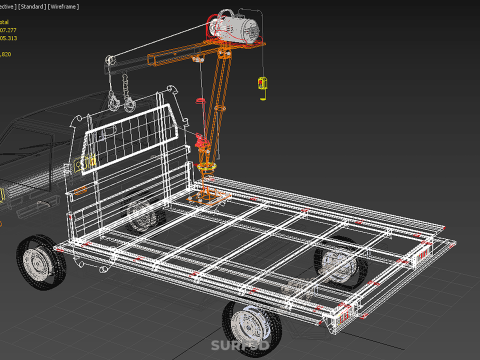

- 多角形:607277

- 頂点:505313

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:285

説明

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

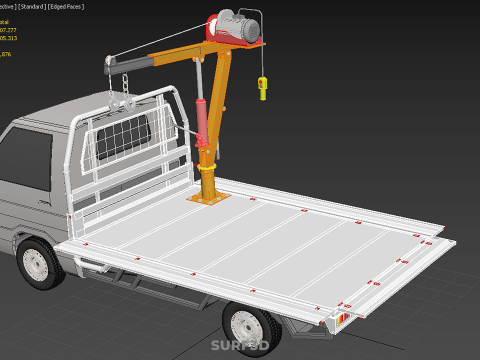

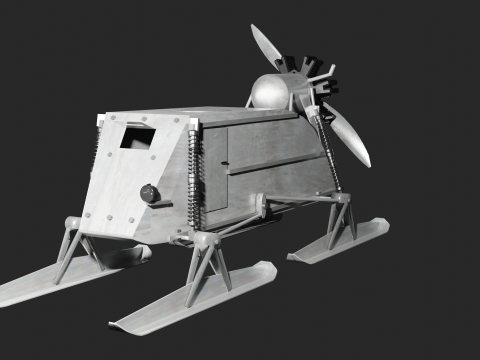

A "Wide Deck Jib Crane Lift Hoist Motor Winch Hook Attached on a Truck Pickup" describes a specialized mobile lifting system comprising a jib crane assembly securely mounted onto a modified pickup truck chassis, specifically utilizing an integrated wide deck for enhanced stability and functional integration. This configuration creates a highly versatile and portable apparatus, designed for lifting, lowering, and manipulating loads in diverse field environments where conventional fixed cranes or larger mobile cranes are impractical or inaccessible.

**Core Components and Functionality:**

The system integrates several key engineering and mechanical components:

1. **Truck Pickup (Base Vehicle):** The foundation of the system is typically a commercial-grade light-duty or medium-duty pickup truck. These vehicles are chosen for their robust chassis, engine power (which can drive hydraulic pumps via a Power Take-Off (PTO) unit), and inherent maneuverability. The truck's mobility enables the crane system to be rapidly deployed to various remote or challenging job sites.

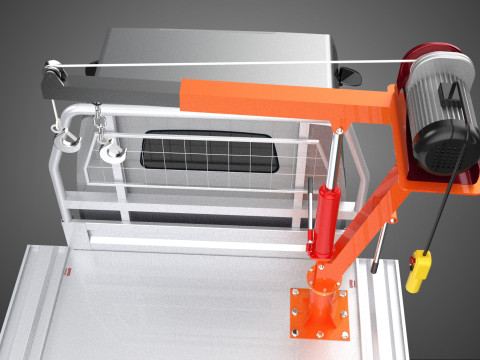

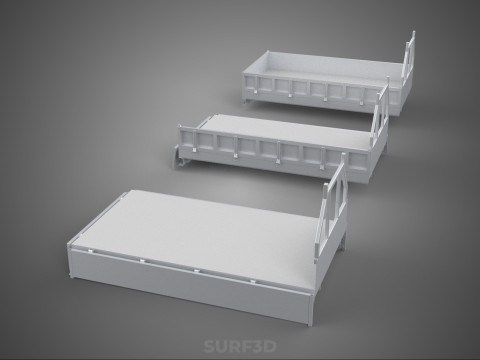

2. **Wide Deck Integration:** The term "wide deck" refers to a specialized, often reinforced, flatbed or utility body installed onto the truck's chassis, replacing or augmenting the standard pickup bed. This deck provides a stable, expansive, and structurally integrated mounting surface for the jib crane's pedestal. It typically incorporates a heavy-duty subframe designed to distribute the crane's operational stresses evenly across the truck's main frame, preventing chassis distortion and enhancing overall stability. Crucially, outriggers or stabilizers are frequently integrated into the deck or truck frame. These extend laterally and vertically to provide a broader, more stable footprint during lifting operations, effectively counteracting tipping moments generated by the crane's load and reach.

3. **Jib Crane Assembly:** The central lifting mechanism is a jib crane, characterized by its horizontal or near-horizontal jib (also known as a boom) that extends from a vertical mast or pillar. This pillar is securely bolted or welded to the truck's wide deck. The jib assembly often features a slewing (rotation) capability, allowing the boom to pivot horizontally, typically through a range of 180 to 360 degrees, depending on the design and stability considerations. The boom itself can be of a fixed length or telescopic, offering adjustable reach for various operational requirements.

4. **Lift Hoist and Motor Winch:** The vertical movement of loads is performed by a hoist, which is directly powered by a motor-driven winch. The winch consists of a rotating drum around which a high-strength steel wire rope or cable is wound. The "motor" can be either electric (typically 12V DC, powered by the truck's electrical system or an auxiliary battery pack) or hydraulic (powered by the truck's engine through a PTO and hydraulic pump system). This motor provides the necessary torque to rotate the winch drum, precisely raising or lowering the attached load.

5. **Hook Attachment:** At the terminus of the wire rope is a robust, swiveling lifting hook. This is the terminal device responsible for securely engaging the load. Hooks are engineered for specific load capacities and are typically equipped with safety latches to prevent accidental disengagement of the load during lifting and transport.

**Operational Principles:**

To operate the system, the truck is precisely positioned, and its integrated outriggers are extended and firmly grounded to ensure maximum stability. The operator then uses a control system (which can be manual, wired remote, or wireless remote) to articulate the jib (slewing and potentially telescoping) and to activate the motor winch, thereby raising or lowering the hook with the attached load. The safe load capacity and operational radius are critical parameters, determined by the crane's design specifications, the truck's inherent stability, and the current extension of the jib. Adherence to manufacturer-provided load charts is paramount for safe operation.

**Applications:**

This mobile lifting system finds widespread application across numerous industries due to its versatility and ability to operate in diverse environments, including:

* **Construction:** Lifting tools, materials, and small machinery onto elevated platforms, into excavations, or across job sites.

* **Utility Services:** Facilitating the handling of transformers, utility poles, pipes, and equipment for electrical, telecommunications, water, and gas crews.

* **Field Service & Maintenance:** Assisting in the lifting and positioning of heavy components during the repair and maintenance of agricultural machinery, heavy equipment, and industrial plant facilities in remote locations.

* **Logistics & Delivery:** Enabling the loading and unloading of heavy or awkwardly shaped cargo from the truck bed at sites lacking dedicated loading docks or material handling equipment.

* **Municipal Services:** Supporting public works, parks and recreation, and sanitation departments with various lifting tasks.

**Advantages and Limitations:**

The primary advantages of this system include exceptional mobility, versatility, and cost-effectiveness when compared to larger, dedicated crane solutions. It allows for independent lifting operations in diverse and often remote locations. However, limitations include a relatively lower lifting capacity and reach compared to specialized heavy-lift cranes, and a critical dependence on proper outrigger deployment and stable ground conditions for safe operation.

**Safety Considerations:**

Safe operation necessitates strict adherence to load charts, manufacturer guidelines, proper stabilization procedures, regular maintenance, and comprehensive operator training. Essential safety features typically include overload protection systems, emergency stop functions, and visual/audible alarms. The overall stability of the truck-crane system, especially on uneven or soft terrain, must be rigorously assessed and maintained to prevent tipping or structural failure.

フォーマットが必要ですか?

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. フリーフォーマット変換3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

使用情報

ワイドデッキ ジブ クレーン リフト ホイスト モーター ウインチ フック トラック ピックアップ カー - このロイヤリティフリーの3Dモデルは、基本ライセンスまたは拡張ライセンスに従って、個人および商用目的で使用できます。基本ライセンスは、デジタル広告、デザインおよび視覚化プロジェクト、ビジネスソーシャルメディアアカウント、ネイティブアプリ、ウェブアプリ、ビデオゲーム、物理またはデジタル最終製品(無料および有償)など、ほとんどの標準的な使用事例をカバーしています。

拡張ライセンスには、基本ライセンスで付与されるすべての権利が使用制限なしで含まれており、ロイヤリティフリーの条件の下で、3Dモデルを無制限の商用プロジェクトで使用できます。

詳細を読む

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी