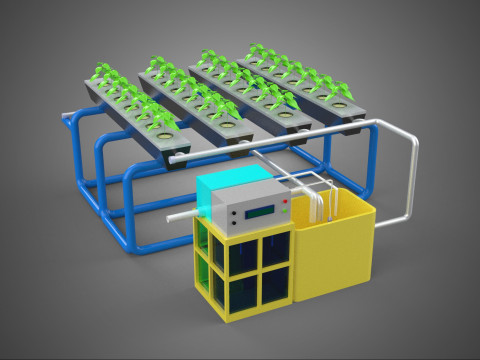

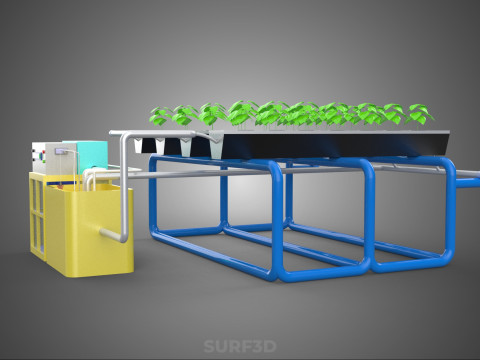

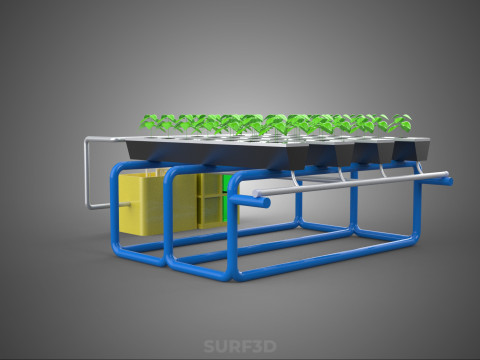

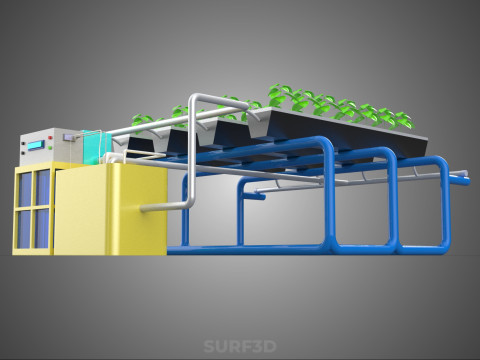

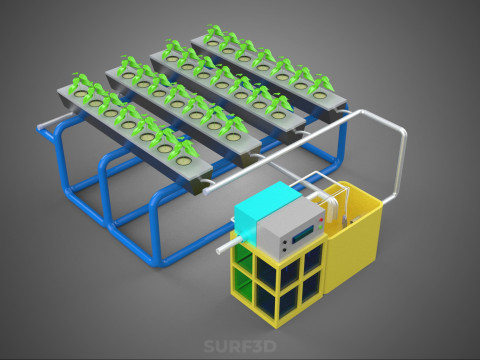

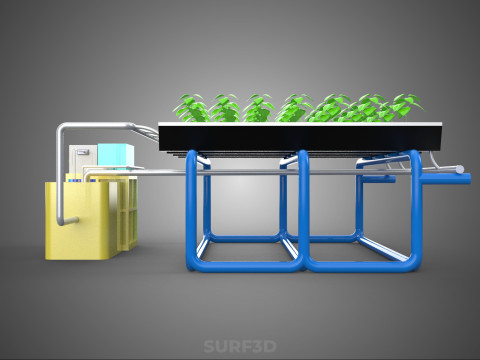

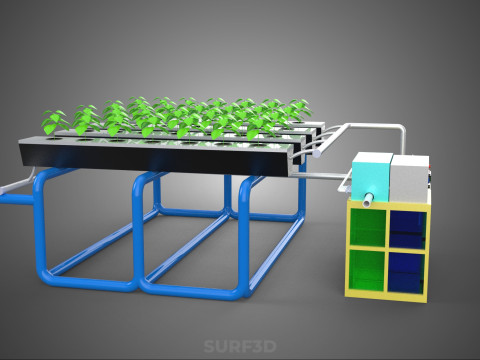

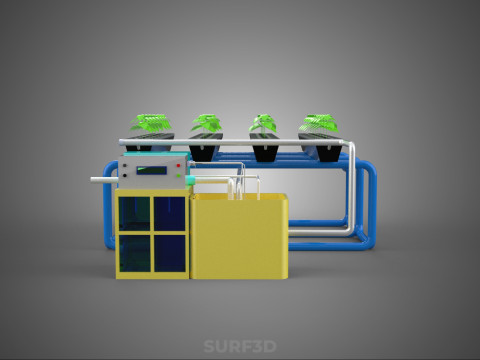

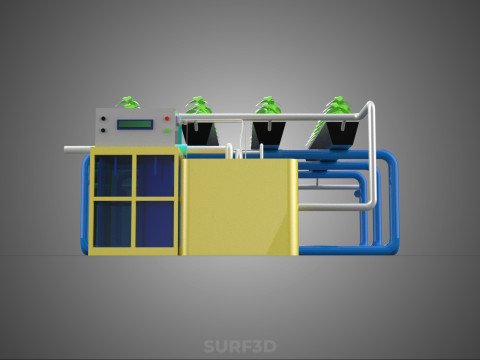

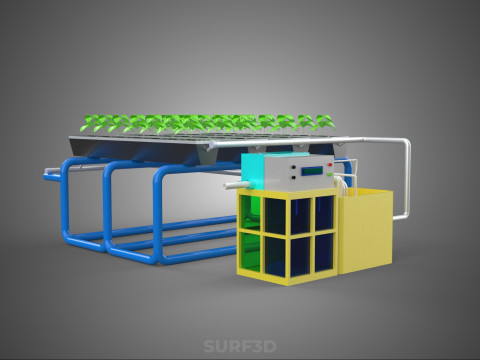

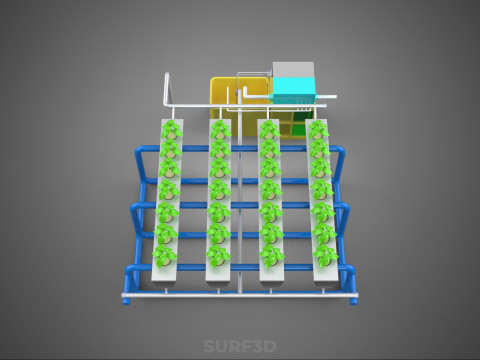

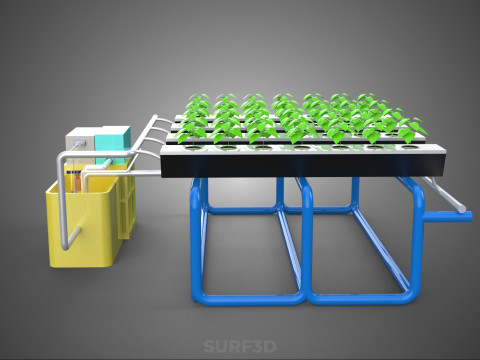

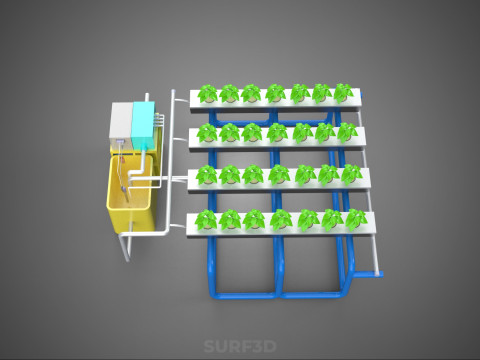

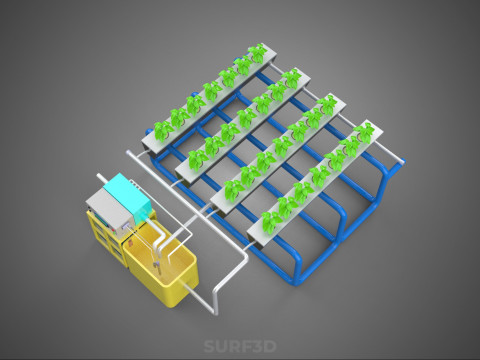

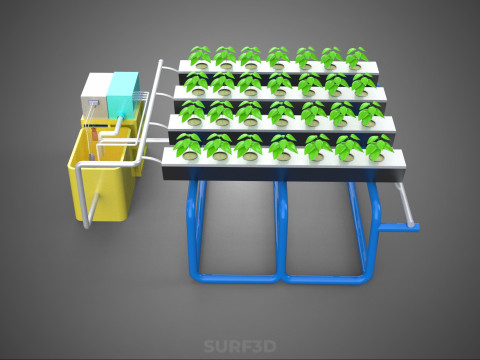

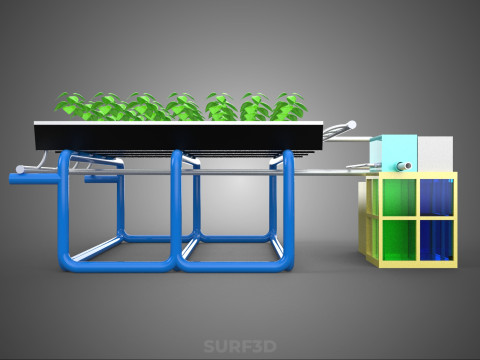

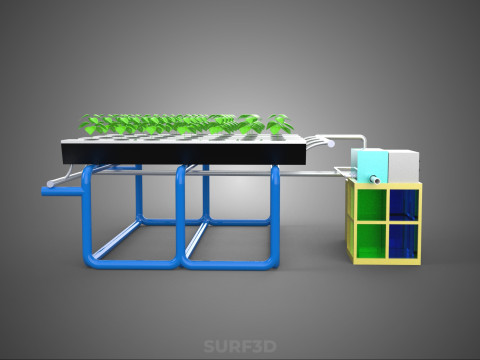

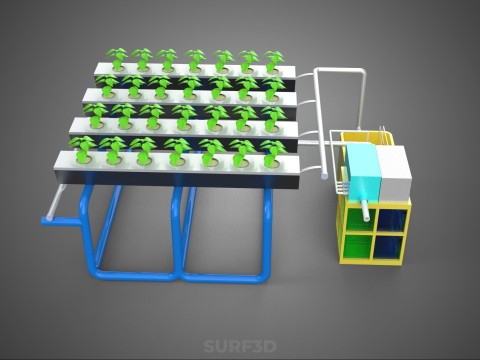

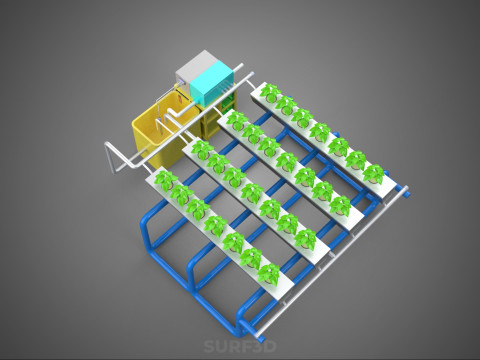

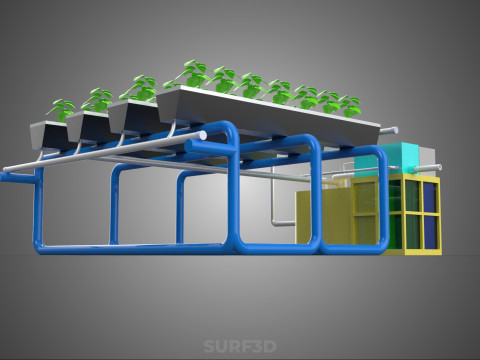

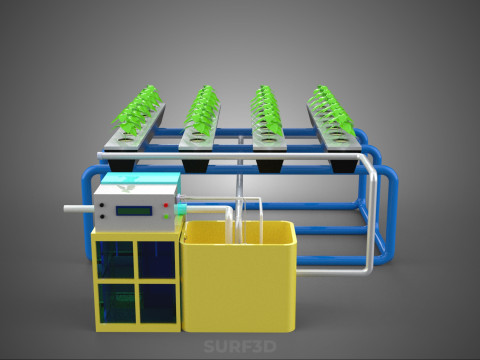

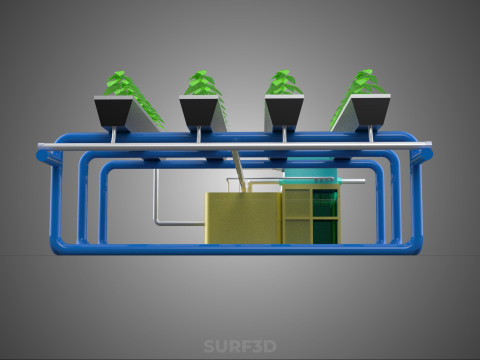

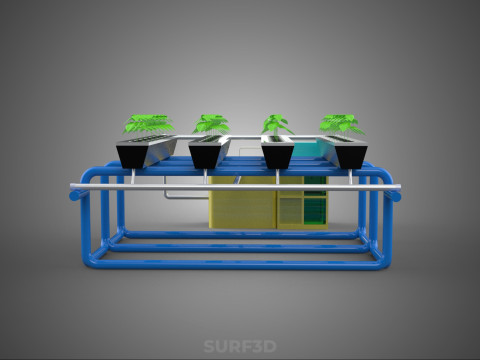

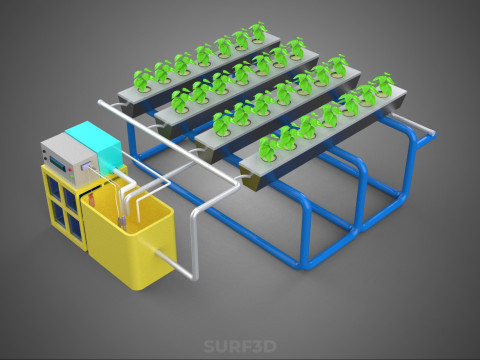

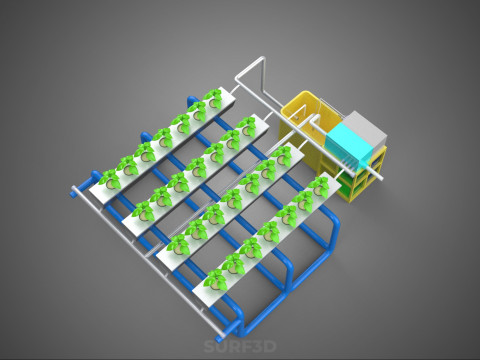

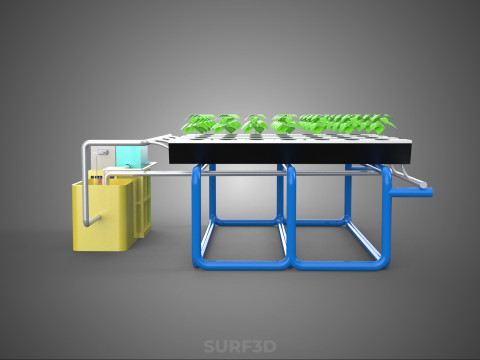

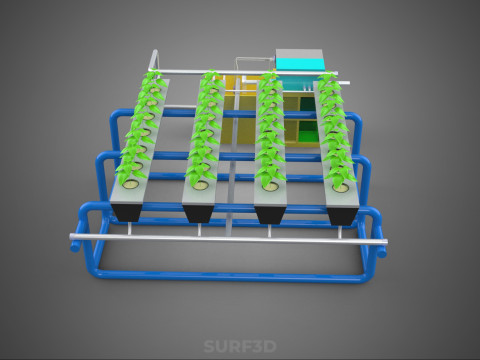

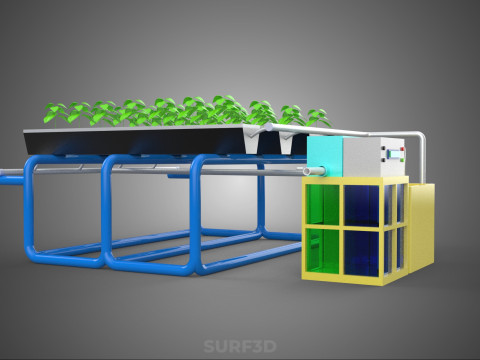

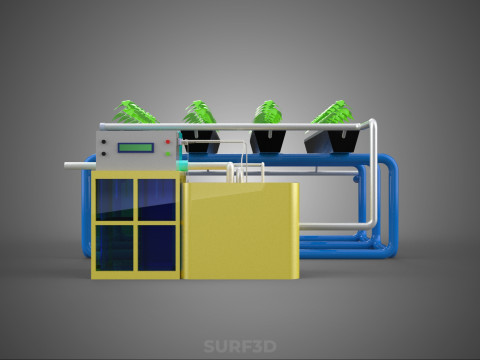

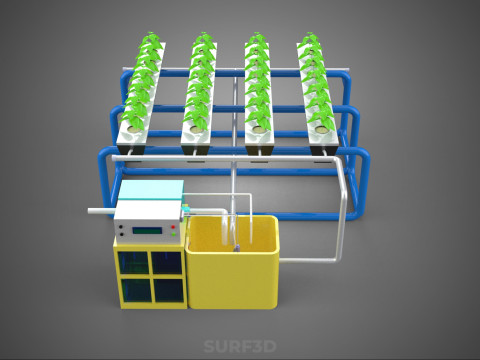

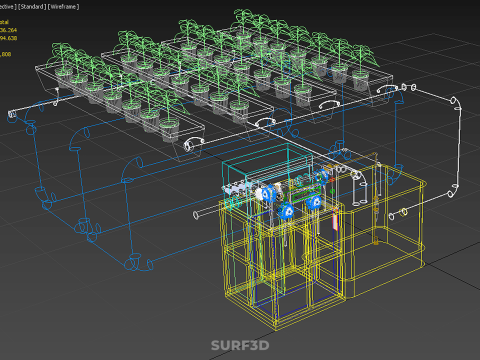

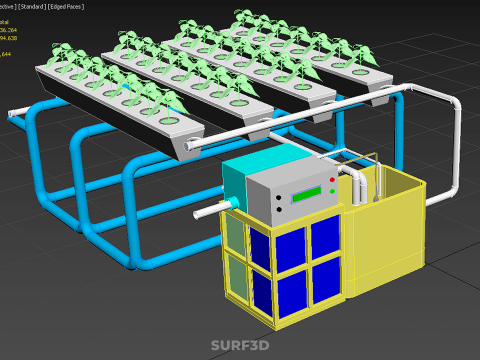

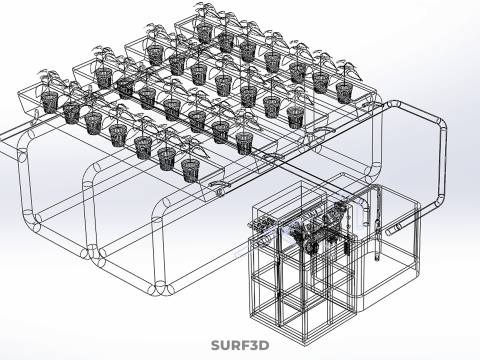

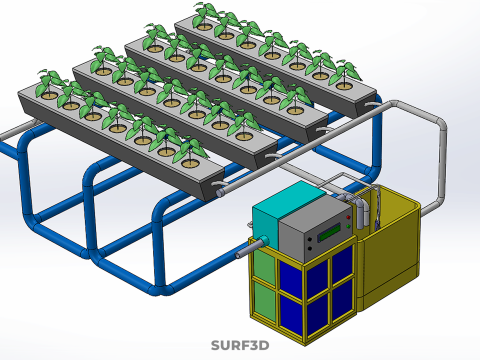

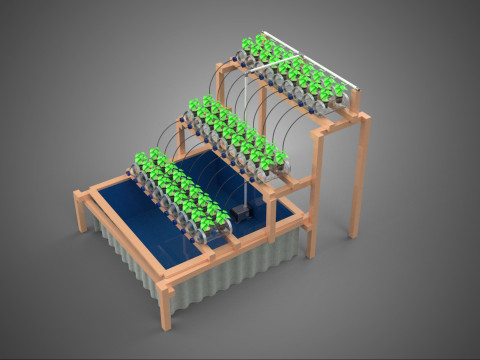

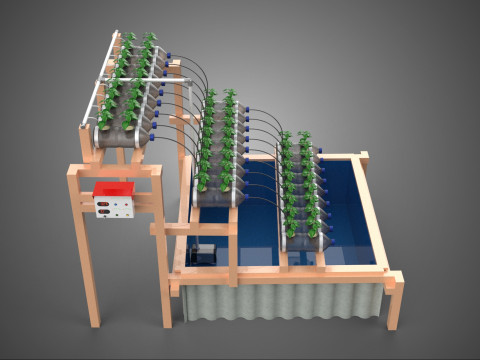

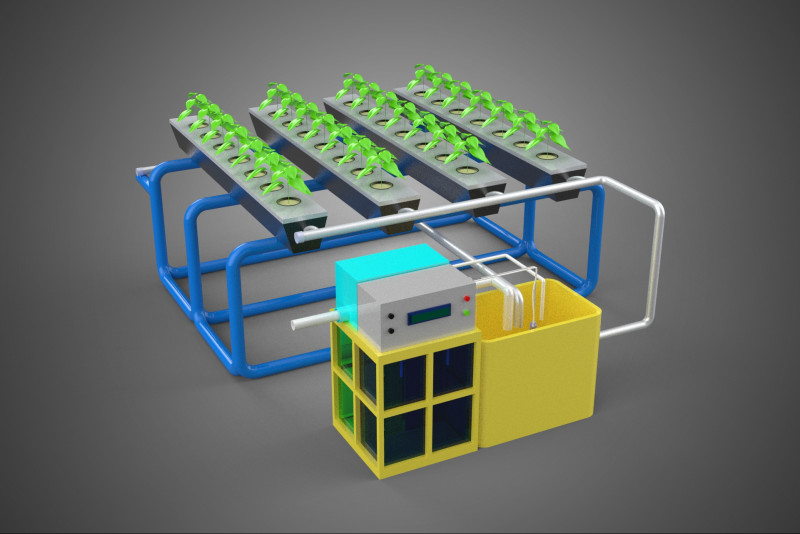

AUTO CONTROL MONITORING NUTRIENT PH NUTRITION HYDROPONIC PLANT 3D Model

- Available formats: Autodesk AutoCAD (.dwg) 3.97 MBIGES (.iges) 3.22 MBSTEP (.step) 2.71 MBGLB (.glb / .gltf) 5.55 MBACIS(.sat) 7.01 MBStereolithography (.stl) 10.19 MBWavefront OBJ (.obj) 9.89 MBBlender3D (.blend) 11.60 MBAutodesk FBX (.fbx) 19.12 MBAutodesk 3DS MAX (.max) 17.81 MB3D Studio (.3ds) 3.92 MBRhinoceros (.3dm) 19.25 MBSketchUp (.skp) 5.76 MBCollada (.dae) 10.00 MB

- Polygons:836264

- Vertices:594638

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Poly NURBS

- Unwrapped UVs:Unknown

- Views:75

- Date: 2025-09-17

- Item ID:599339

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

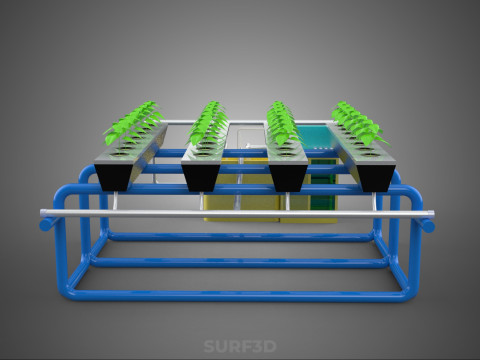

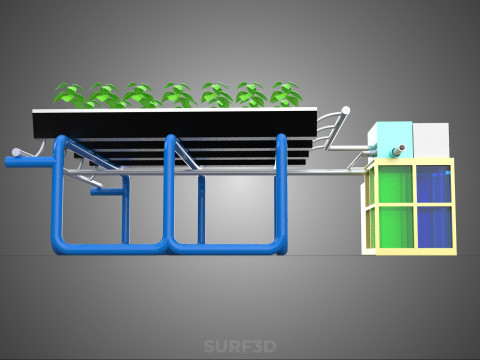

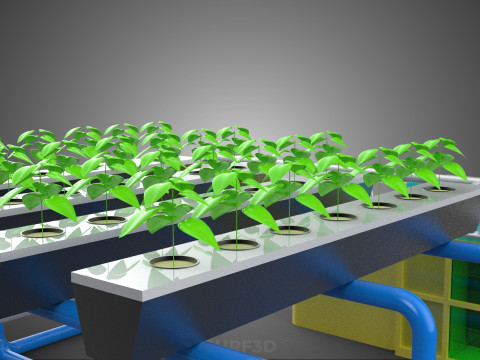

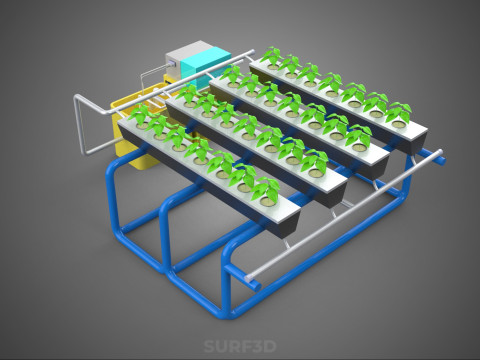

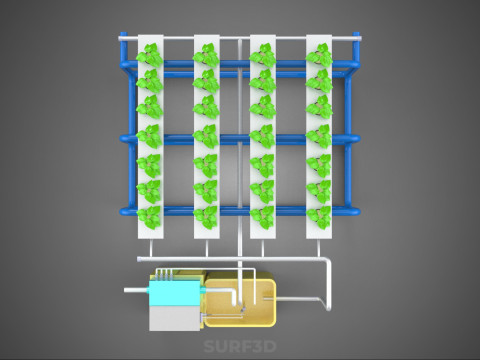

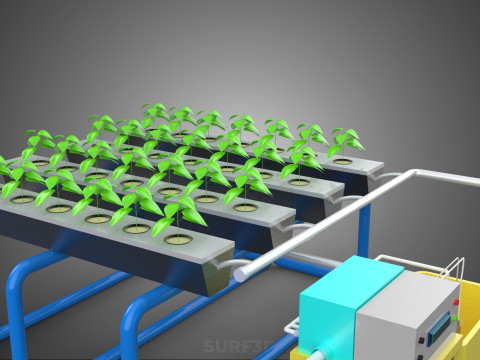

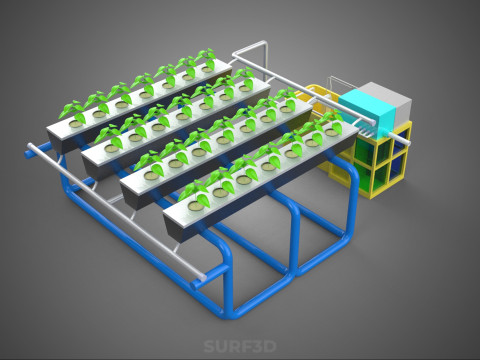

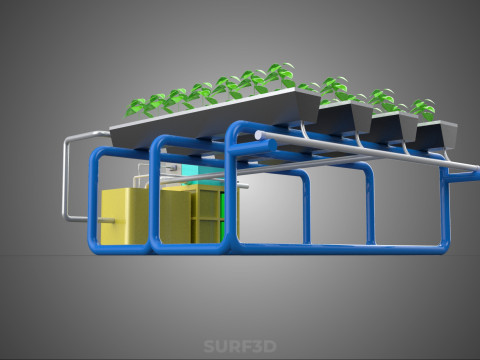

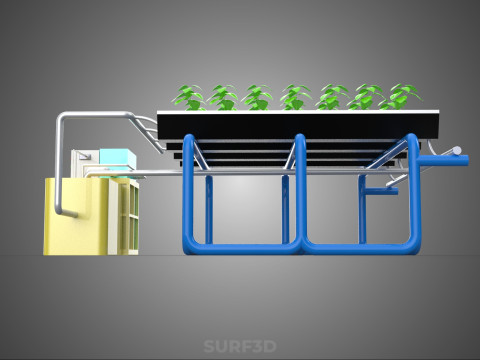

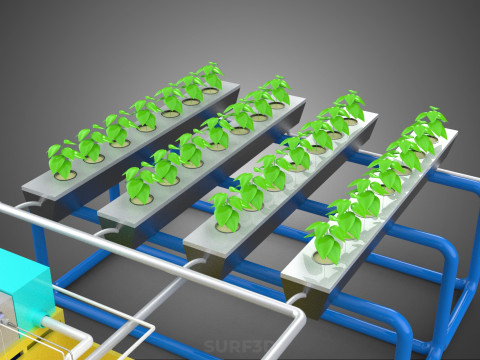

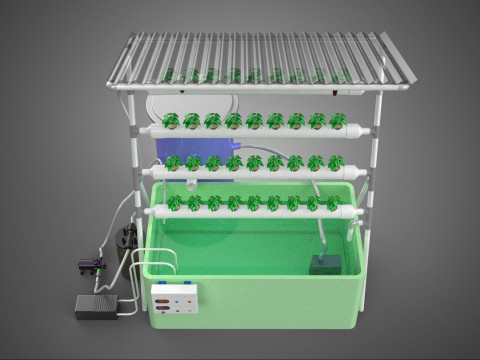

An "Auto Control Monitoring Nutrient pH Nutrition Hydroponic Plant" system refers to a sophisticated technological integration designed to autonomously regulate and maintain optimal pH levels within the nutrient solution supplied to hydroponically cultivated plants. This class of system is fundamental to advanced hydroponic agriculture, where precise environmental control is paramount for maximizing plant growth, yield, and overall health. Its primary objective is to ensure that essential plant nutrients remain bioavailable by keeping the nutrient solution's pH within a specific, plant-species-dependent range.

In hydroponics, plants absorb mineral nutrients directly from a water-based solution rather than soil. The pH (potential of hydrogen) of this nutrient solution is a critical parameter that dictates the solubility and uptake efficiency of these essential ions. Each nutrient has an optimal pH range for absorption; deviations from this range can lead to nutrient lockout, where nutrients are present in the solution but are chemically unavailable to the plant roots. This can result in nutrient deficiencies, stunted growth, and reduced yields, despite adequate nutrient concentrations. Most horticultural crops thrive in a slightly acidic pH range, typically between 5.5 and 6.5, though specific requirements vary.

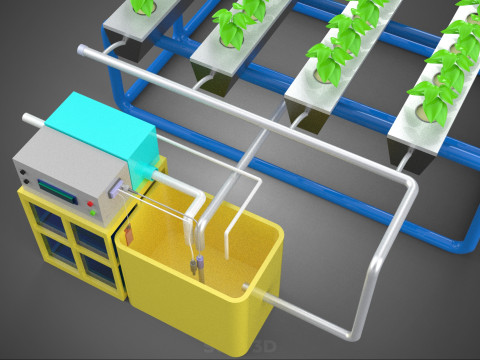

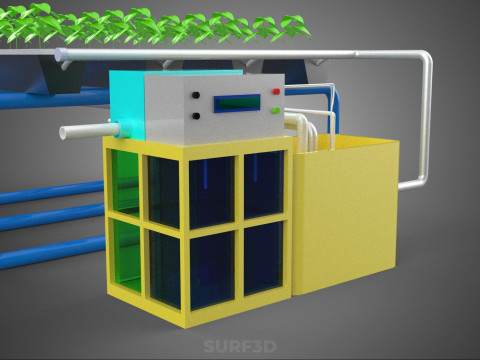

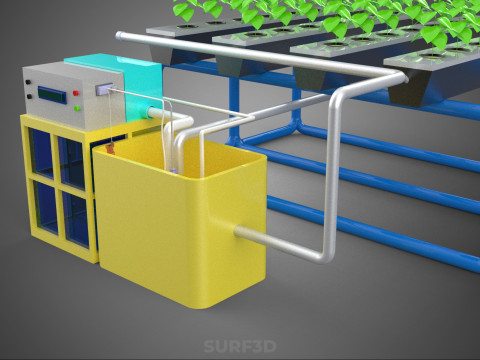

The monitoring aspect of such a system relies on robust and accurate pH sensors, often glass electrodes, immersed directly into the nutrient reservoir or a continuously flowing bypass line. These sensors generate an electrical signal proportional to the hydrogen ion concentration, which is then transmitted to a digital controller. The controller continuously reads and processes this data, providing real-time pH measurements. Modern systems may integrate data logging capabilities, allowing growers to track pH trends over time and analyze the stability and dynamics of their nutrient solution.

The 'auto control' mechanism leverages the real-time pH data to automatically adjust the solution's acidity or alkalinity. When the monitored pH deviates from the user-defined setpoint (the target pH range), the controller activates precision dosing pumps. These pumps dispense minute quantities of pH-adjusting solutions—typically an acid (e.g., phosphoric acid, nitric acid) to lower pH or a base (e.g., potassium hydroxide) to raise pH—into the nutrient reservoir. The system then waits for the solution to homogenize and re-measures the pH, repeating the dosing process until the target range is re-established. Advanced controllers may employ proportional-integral-derivative (PID) algorithms for more precise and stable control, minimizing overshooting and oscillation around the setpoint.

While primarily focused on pH, these auto-control systems are often integrated into broader nutrient management platforms. This frequently includes monitoring and controlling Electrical Conductivity (EC), which measures the total concentration of dissolved salts (nutrients) in the solution. An integrated system can automatically adjust both pH and EC, ensuring a comprehensive and dynamic approach to nutrient delivery. Some systems also manage water levels, temperature, and even dissolved oxygen, creating a fully optimized hydroponic environment.

The implementation of auto-controlled pH monitoring offers numerous benefits:

1. **Optimized Nutrient Uptake:** Ensures maximum availability and absorption of essential minerals, preventing deficiencies and toxicities.

2. **Consistent Growth Rates:** Maintains a stable root zone environment, leading to more predictable and vigorous plant development.

3. **Reduced Labor:** Eliminates the need for manual, frequent pH testing and adjustment, freeing up grower time for other tasks.

4. **Increased Yield and Quality:** By preventing stress and optimizing nutrition, plants can achieve their full genetic potential.

5. **Resource Efficiency:** Prevents nutrient lockout, potentially reducing nutrient solution waste and improving fertilizer efficiency.

6. **Data-Driven Insights:** Data logging provides valuable information for system calibration, troubleshooting, and long-term optimization strategies.

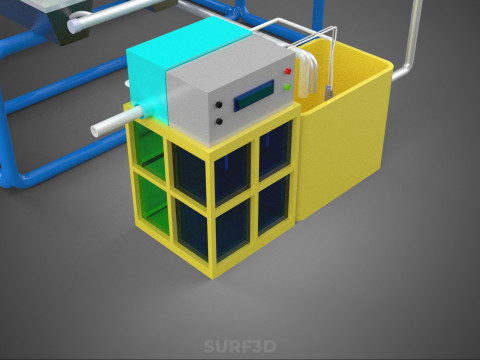

A typical auto control monitoring pH system comprises:

* **pH Sensor (Electrode):** For real-time measurement.

* **Controller/Dosing Computer:** Interprets sensor data, processes algorithms, and actuates dosing pumps.

* **Dosing Pumps:** Peristaltic or diaphragm pumps for precise delivery of pH adjusters.

* **pH Adjuster Solutions:** Acidic (pH Down) and/or basic (pH Up) solutions.

* **Nutrient Reservoir:** The container holding the nutrient solution.

* **Mixing Device:** An air stone or pump to ensure uniform distribution of adjusters.

* **Calibration Solutions:** For periodic sensor calibration.

Despite their advantages, these systems require careful consideration. Sensors need periodic calibration and replacement due to drift and degradation. Dosing pumps and lines can become clogged. The quality and purity of pH adjusters are important, as contaminants can harm plants. Initial setup and programming of setpoints and dosing parameters require horticultural knowledge. Furthermore, robust power supply and fail-safe mechanisms are crucial to prevent catastrophic pH swings in case of system malfunction.

In conclusion, auto control monitoring nutrient pH systems represent a cornerstone of modern, efficient, and sustainable hydroponic cultivation. By automating the most critical aspect of nutrient solution management, they empower growers to achieve superior plant performance, reduce operational costs, and elevate the precision of controlled environment agriculture, moving towards truly autonomous and optimized plant factories.

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी