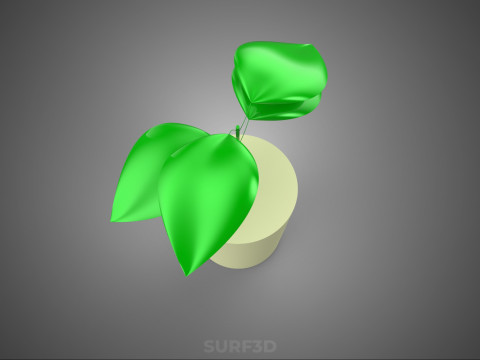

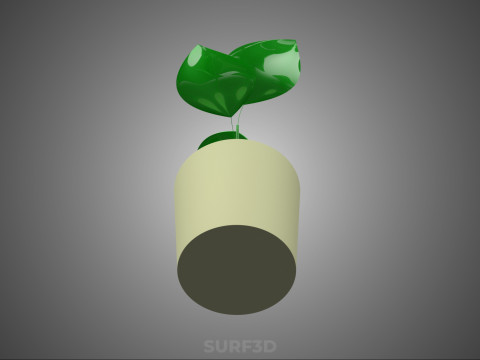

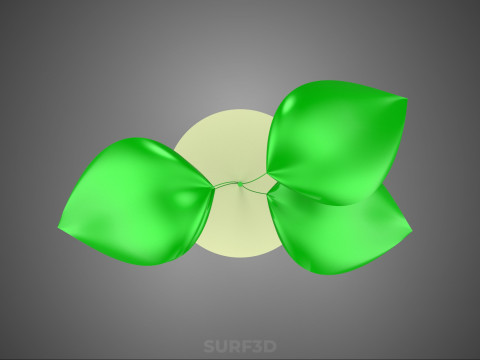

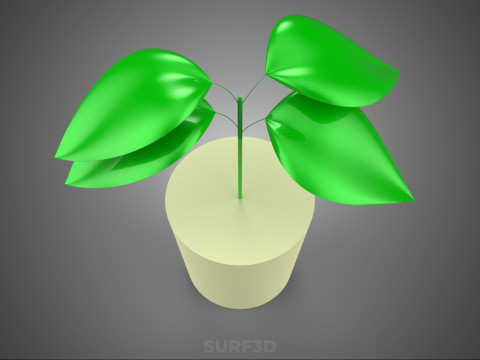

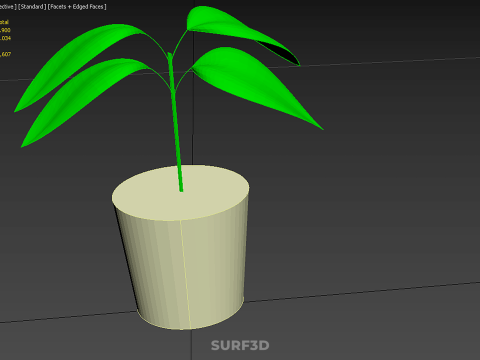

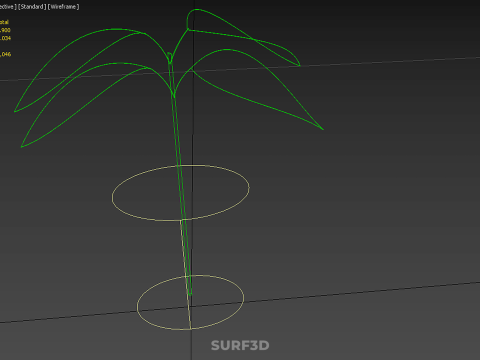

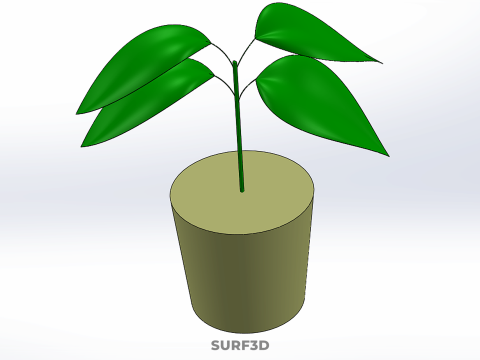

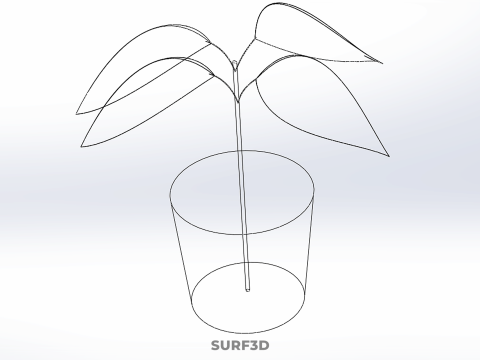

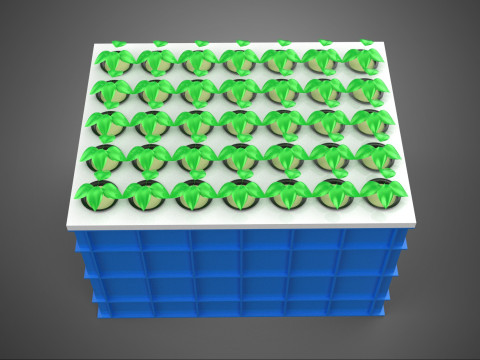

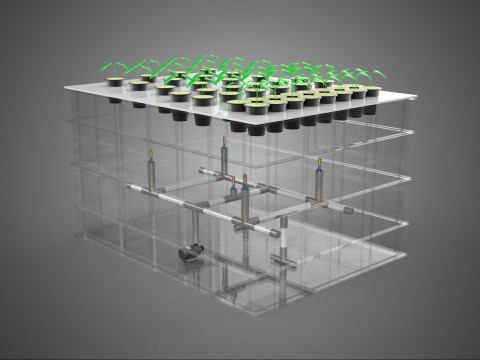

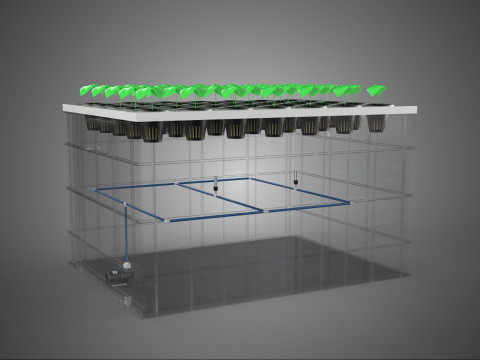

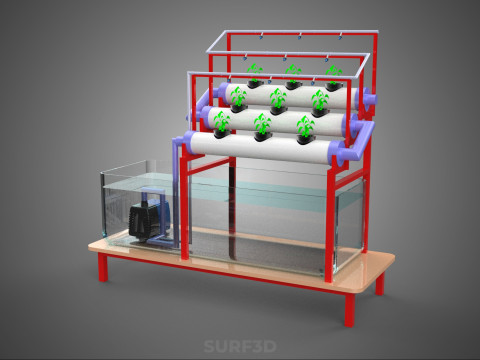

POLYURETHANE FOAM SPONGE ROCKWOOL HORTICULTURAL PU PLANT MEDIA 3D Model

- Request product support by the author

- Available formats:

- Item ID:615984

- Date: 2025-12-05

- Polygons:7900

- Vertices:5034

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Poly NURBS

- Unwrapped UVs:Unknown

- Views:44

Description

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

**POLYURETHANE FOAM SPONGE ROCKWOOL HORTICULTURAL PU PLANT MEDIA**

This classification denotes a specialized category of synthetic, inert substrates utilized extensively in controlled environment agriculture (CEA), particularly within hydroponic, aeroponic, and highly precise nursery operations. These materials are engineered composites that integrate the structural integrity and moisture regulation capabilities of polymeric matrices (Polyurethane Foam) with the exceptional capillary function and chemical stability of mineral wool fibers (Rockwool), optimized for root zone development and efficient nutrient delivery.

### I. Composition and Materials Science

The resulting medium is characterized by its high porosity and consistency, designed to provide an optimal balance between water retention and air-filled porosity (AFP), critical for aerobic respiration of plant roots.

#### A. Polyurethane (PU) Foam Matrix

Polyurethane, typically formulated from the reaction of polyols and isocyanates, forms the primary scaffold of the substrate. For horticultural applications, the resultant foam is overwhelmingly open-cell in structure, creating a sponge-like network of interconnected pores. This structure facilitates the rapid dispersal and retention of aqueous nutrient solutions (fertigation). Customized manufacturing processes often modify the PU to enhance hydrophilicity, ensuring immediate and thorough saturation upon initial wetting and promoting strong adhesion to plant roots. The mechanical robustness of the PU matrix prevents structural degradation or compaction, ensuring stable volume and consistent aeration throughout the crop cycle.

#### B. Rockwool (Mineral Wool) Component

Rockwool, or stone wool, is manufactured by melting basalt, diabase, or other igneous rocks and spinning the molten material into fine, fibrous strands. This material is inherently chemically inert, offering negligible Cation Exchange Capacity (CEC) and maintaining a neutral pH, which is highly advantageous for precise control over the nutrient solution chemistry. When integrated into the PU matrix, the Rockwool fibers increase the density of the medium and significantly enhance capillary action, facilitating the vertical and horizontal movement of water and nutrients, particularly crucial in larger substrate slabs.

#### C. Composite Structure (Sponge)

The term "sponge" refers to the highly porous nature—often exceeding 90% total porosity—which ensures that even when saturated, adequate levels of oxygen remain within the root zone. This open, resilient structure distinguishes these media from dense organic substrates prone to waterlogging and subsequent root hypoxia. The integrated media are typically molded or cut into standardized plugs, cubes, or slabs suitable for automated handling and transplantation.

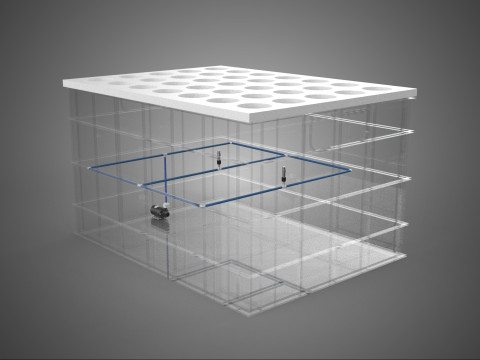

### II. Horticultural Performance and Advantages

Polyurethane foam/rockwool composites offer distinct advantages over traditional organic substrates (e.g., peat moss, coco coir) and monolithic rockwool blocks in demanding commercial settings:

1. **Chemical Inertness and Sterility:** The synthetic nature ensures the absence of inherent pathogens, weed seeds, or nutrient salts, providing growers complete, immediate control over the starting environment.

2. **Optimized Water Dynamics:** The combination of PU and Rockwool allows for high Water Holding Capacity (WHC) while simultaneously maintaining a high AFP, crucial for robust seedling establishment and cloning. The media drain rapidly yet resist desiccation.

3. **Consistency and Uniformity:** Unlike natural media, manufactured composites offer highly reproducible physical properties, leading to uniform crop development across large cultivation areas.

4. **pH and EC Stability:** The substrate itself is chemically stable, minimizing fluctuations in pH or Electrical Conductivity (EC) that could hinder nutrient uptake.

5. **Ease of Use:** Standardized geometric shapes facilitate transplanting and integration into automated seeding lines, minimizing manual labor and improving propagation efficiency.

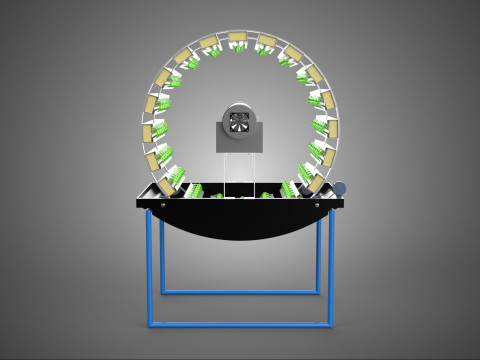

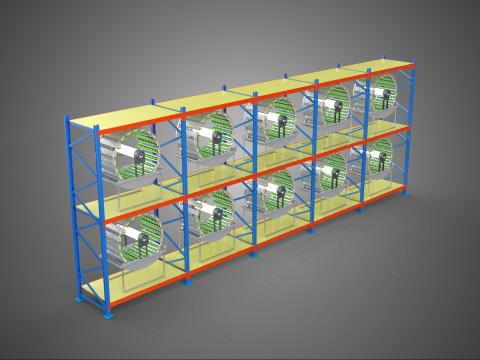

### III. Applications

These composite substrates are primarily deployed during the propagation phase of high-value crops, including:

* **Seedling Starting:** For vegetables (e.g., tomatoes, peppers) and leafy greens (e.g., lettuce, herbs) destined for larger hydroponic systems.

* **Cloning:** Providing sterile, stable support for vegetative cuttings.

* **Microgreens and Shoots:** Used in dense, short-cycle cultivation systems where stability and precise moisture control are paramount.

* **Ornamentals:** Initial rooting of cuttings prior to potting or field placement.

KEYWORDS: Hydroponics, Soilless Culture, Polyurethane, Rockwool, Mineral Wool, Substrate, Growing Media, Propagation, Seed Starting, Cloning, Open-Cell Foam, Hydrophilic, Inert Media, CEA, Vertical Farming, Greenhouse, Water Holding Capacity, Air Filled Porosity, Root Zone, Fertigation, pH Stability, Polymer Matrix, Basalt Fiber, Seedling Plug, Capillary Action, Nutrient Solution, Aeration, Horticulture, Commercial Agriculture, Controlled Environment, Porosity.

Need more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Free Format ConversionWe do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

Usage Information

POLYURETHANE FOAM SPONGE ROCKWOOL HORTICULTURAL PU PLANT MEDIA - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी