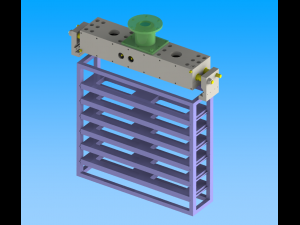

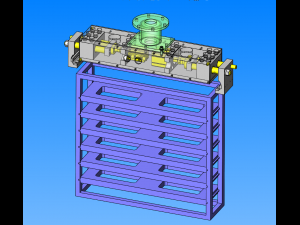

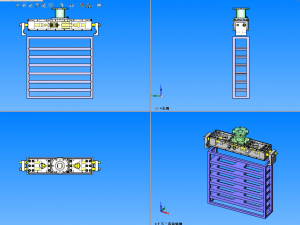

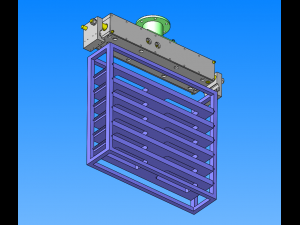

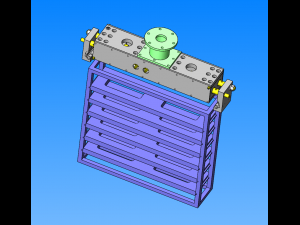

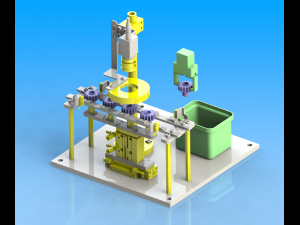

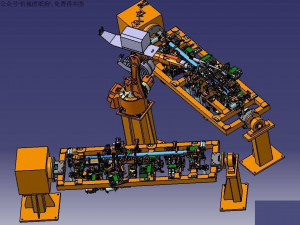

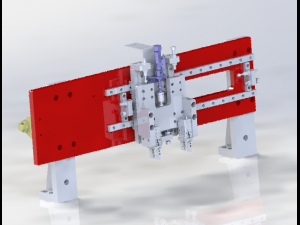

clamping mechanism of heavy workpiece 3D Model

$

6.00 USD

You have $0.00 Credits. Buy Credits

- Available formats: SolidWorks (.sldprt) 7.12 MB

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- Geometry:Polygonal

- Unwrapped UVs:Unknown

- Views:2739

- Date: 2020-07-15

- Item ID:301997

clamping mechanism of heavy workpiece 3D Model sldprt, from tzd

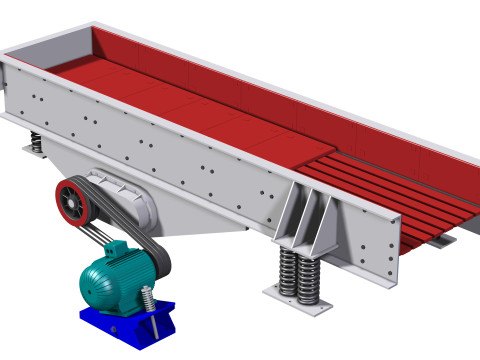

purpose and actionwhen clamping heavy-duty workpieces, the claw clamping mechanism is used instead of the large inner diameter cylinder.

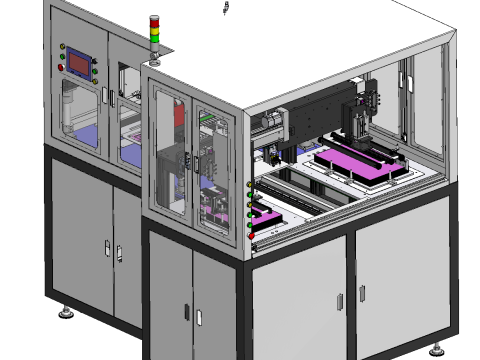

environment and operability

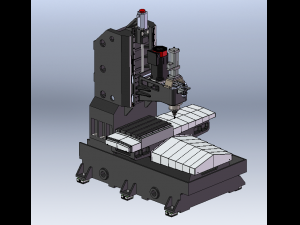

the device acts as a manipulator connected to the front end of the manipulator.

the air supplied by the arm drives the cylinder to open and close the manipulator.

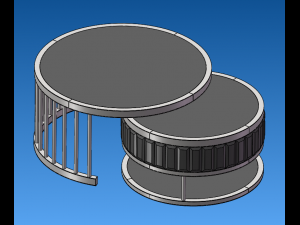

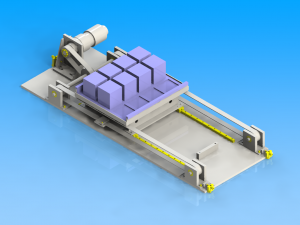

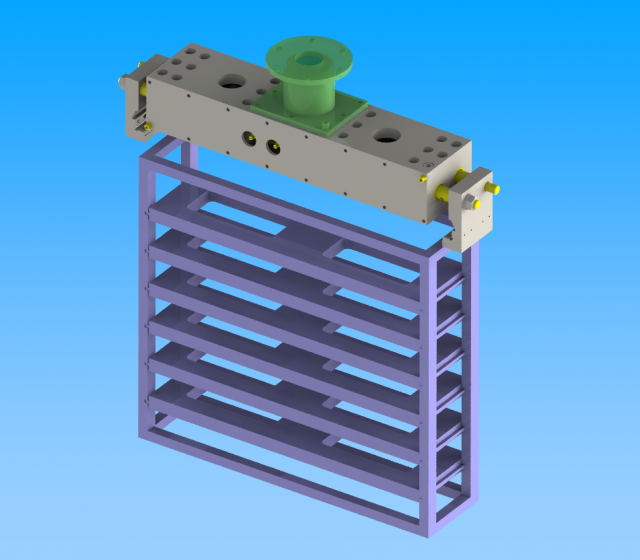

object artifact

workpiece

dimensions: w573 x d150 x h15mm

weight: 5.4kg

workpiece rack

dimensions: w153 x d600 x h102mm

weight: 15.3kg

characteristic

specification and size

unit as a whole

maximum dimension: w695 (with manipulator open) x d137 x h149mm

profile size: w560 x d137 x h102mm

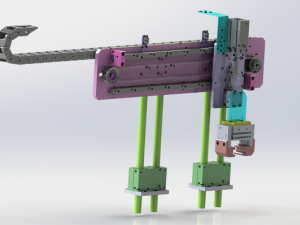

cylinder

reference side: cylinder diameter φ 50mm, stroke 30mm

attached side: cylinder diameter φ 40mm, stroke 30mm

workpiece action

horizontal jump acceleration fixed: 0.2g

instantaneous maximum horizontal jump acceleration: 1g

accuracy and load

the inertia force at the maximum acceleration of horizontal runout is less than the retraction side thrust of cylinder.

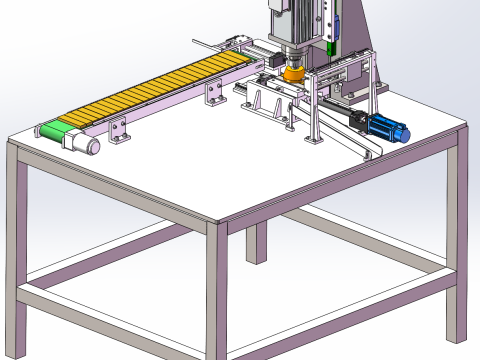

selection basis of main parts

safe cylinder capacity for handling.

key points of design

calculation process of main parts

φ 40mm cylinder output (when horizontal runout is 1g)

inertia force of cylinder: f = ma = (m1 + m2) a

total weight of workpiece: m1 = 6 × 5.4 + 15.3 = 47.7kg

overall weight of manipulator: m2 = 2.11kg

→ f=(47.7+2.11)×9.8=4**n

retraction thrust: f2 = η xa2xp

load rate: η = 1 (according to product catalogue)

retracted pressure area: a2 = 1056 mm 2 (according to product catalogue)

service pressure: p = 0.5mpa

f2=1 x 1056 x 0.5 = 528n

safety factor: f2 / f = 528 / 4** = 1.08 times

key points of structure making and design

using two guide shafts on one side, the reaction force borne by the manipulator is offset by the shear force between the guide shaft and the fixed seat, and the torque will not be transmitted to the cylinder structure.

there is a through-hole on the sliding surface of the guide shaft, so oil-free bushing is used. Print Ready: No

Need more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. We do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!Usage Information

clamping mechanism of heavy workpiece - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

Do you provide Money Back Guarantee?

Yes, we do. If you purchased a product and found some error in the renders or description, we'll try to fix the problem as soon as possible. If we cannot correct the error, we will cancel your order and you will get your money back within 24 hours from downloading the item. Read more conditions hereKeywords

There are no comments for this item.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी