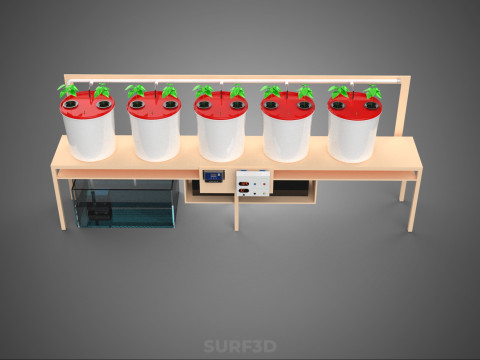

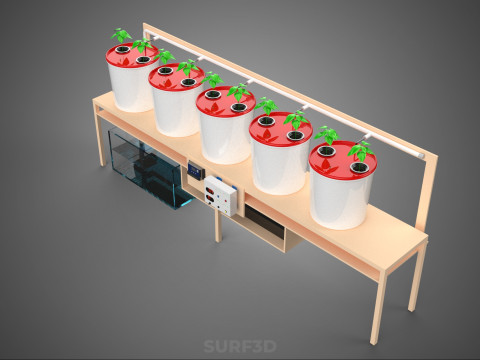

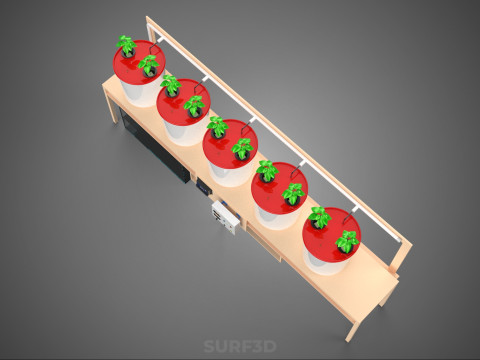

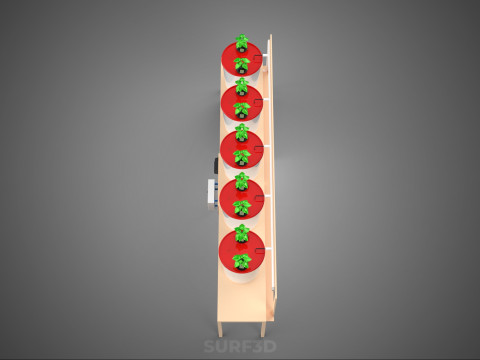

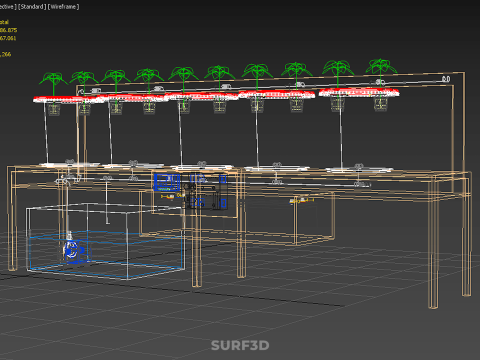

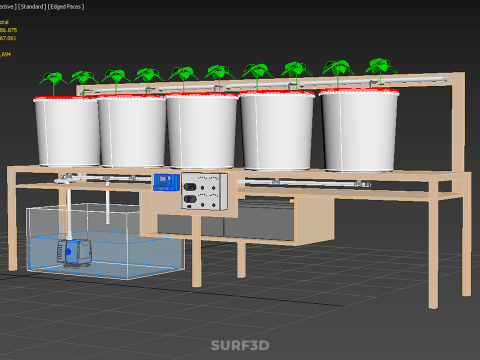

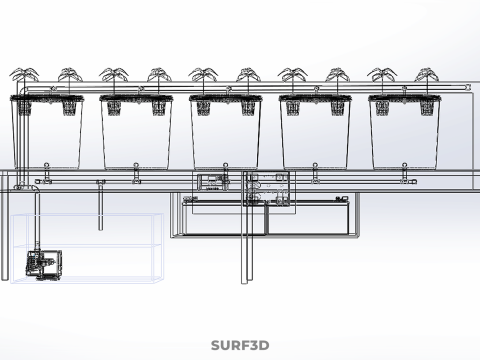

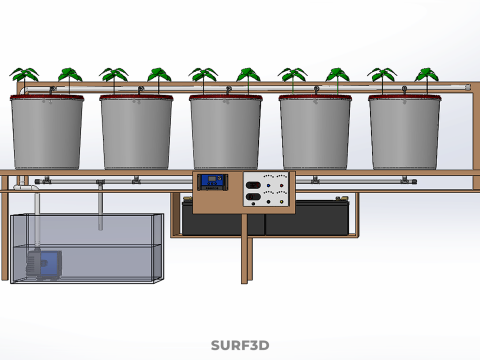

IOT PLANT POT RECIRCULATING HYDROPONIC DUTCH BUCKET SYSTEM SETUP 3D Model

- Request product support by the author

- Available formats:

- Item ID:617255

- Date: 2025-12-11

- Polygons:586875

- Vertices:467061

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Poly NURBS

- Unwrapped UVs:Unknown

- Views:56

Description

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

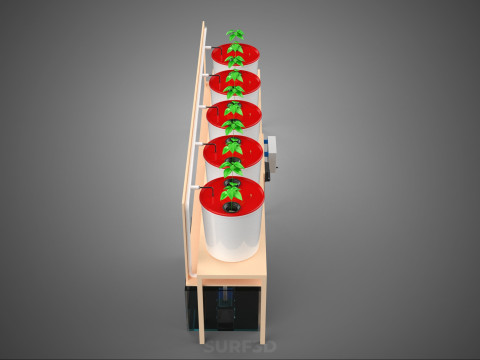

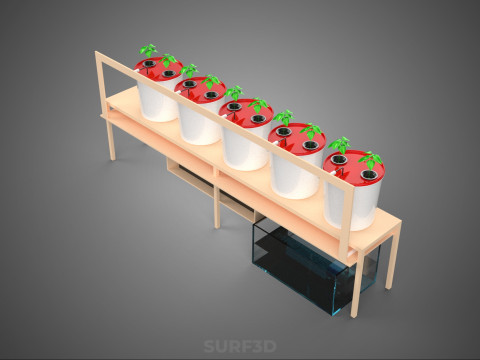

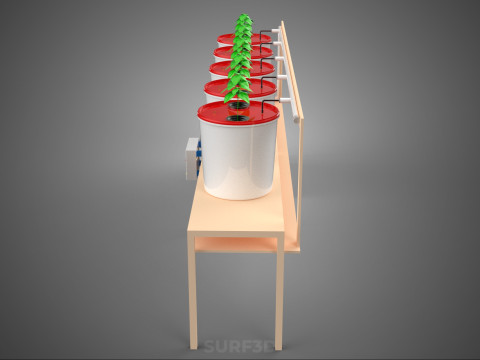

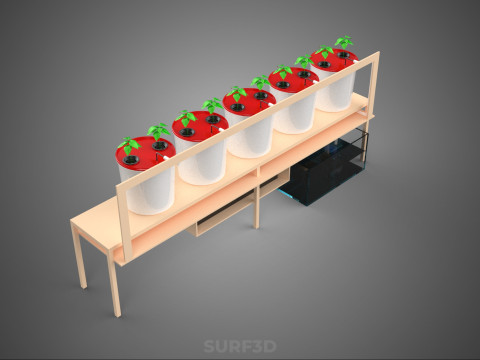

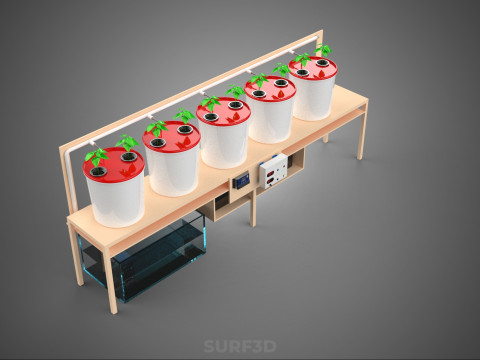

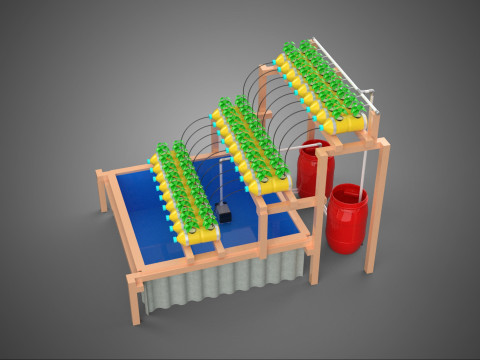

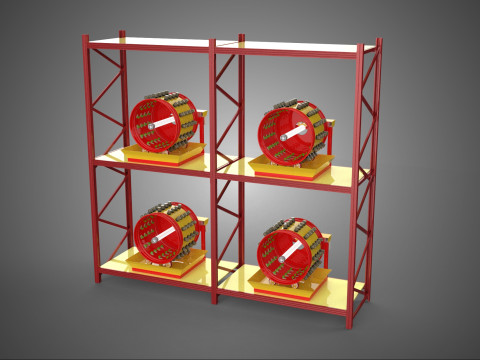

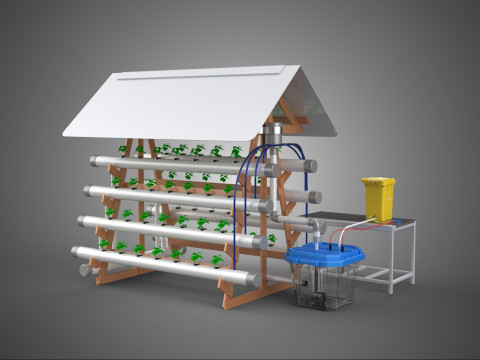

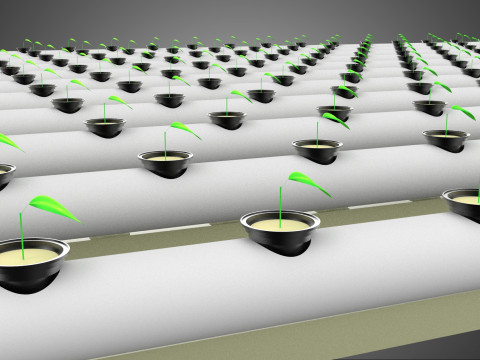

## IOT PLANT POT RECIRCULATING HYDROPONIC DUTCH BUCKET SYSTEM SETUP

An IOT Plant Pot Recirculating Hydroponic Dutch Bucket System Setup represents a specialized, controlled-environment agriculture (CEA) methodology that integrates modular hydroponics, specifically the Bato Bucket technique, with Internet of Things (IoT) technology for enhanced automation and precision control. This hybrid system aims to optimize resource utilization, increase yield predictability, and facilitate remote management of horticultural operations.

### System Architecture (Bato Bucket Hydroponics)

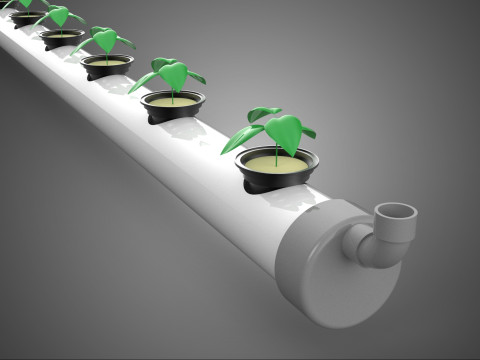

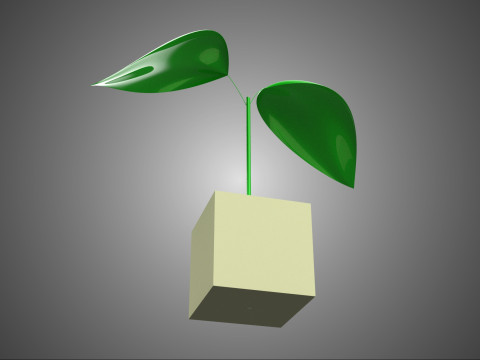

The Dutch Bucket system, often referred to as the Bato Bucket system, is a type of drip hydroponics designed for growing larger, fruiting crops such as tomatoes, peppers, and cucumbers, or large modular plant installations. The physical setup is characterized by individual, interconnected containers (buckets) that function as plant pots, typically utilizing an inert, non-soil medium such as perlite, coco coir, or rockwool.

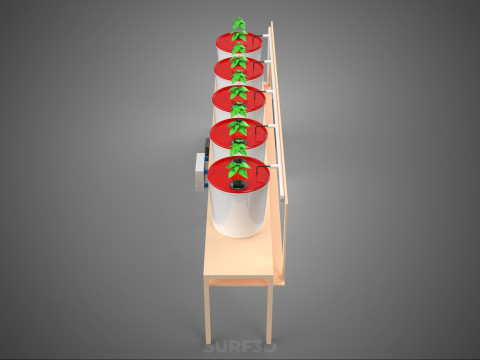

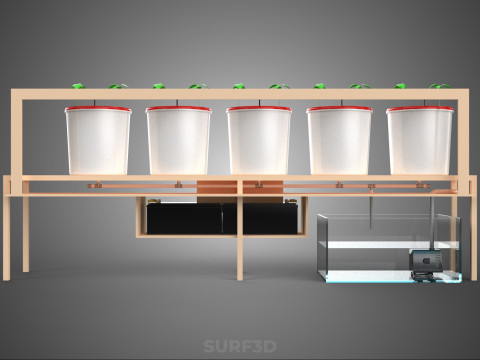

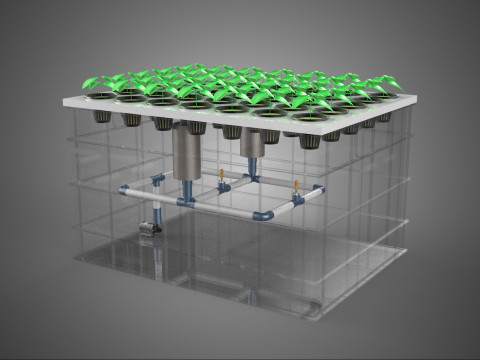

1. **Reservoir:** A large centralized tank holds the nutrient solution (a precise mixture of mineral salts dissolved in water).

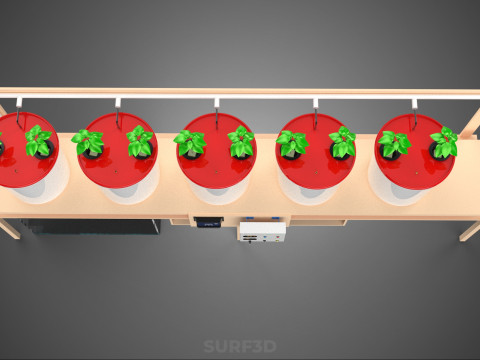

2. **Delivery System:** A submersible pump draws the solution from the reservoir and pushes it through a main supply line. Secondary drip emitters deliver the solution directly to the base of each individual bucket.

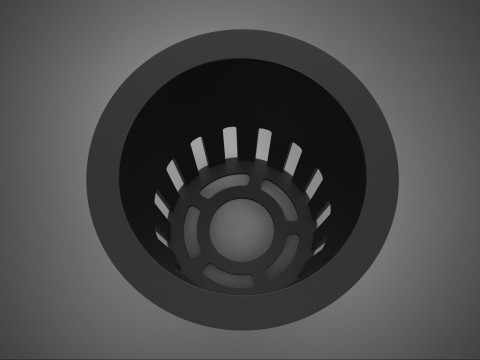

3. **Buckets (Plant Pots):** Each bucket holds the plant and substrate. Crucially, the buckets are designed with a specific drainage mechanism. The nutrient solution is delivered via drip, saturates the root zone, and excess runoff drains from a designated exit port at the bottom of the bucket. This drainage design ensures that a small reserve of solution remains within the bucket, preventing complete drying while promoting aeration (non-deep water culture).

4. **Recirculation Manifold:** The drainage from all individual buckets is collected via a common return line, which uses gravity to channel the unused nutrient solution back into the central reservoir for reuse. This recirculation minimizes water and nutrient waste.

### IOT Integration and Automation

The integration of IoT elevates the Dutch Bucket setup from a passive hydroponic system to an active, closed-loop control environment. The primary objective is to maintain the nutrient solution parameters within the ideal range required for optimal plant growth without manual intervention.

#### 1. Sensing and Data Acquisition

Microcontrollers (e.g., Arduino, ESP32) serve as the processing unit, interfacing with specialized sensors to monitor critical environmental and nutrient parameters:

* **Electrical Conductivity (EC):** Measures the concentration of dissolved mineral salts (nutrients) in the solution. This determines the overall feeding strength.

* **pH:** Monitors the acidity or alkalinity of the solution, which directly affects the plant's ability to absorb essential elements. The optimal range is typically maintained between 5.5 and 6.5, depending on the crop.

* **Water Temperature:** Affects dissolved oxygen levels and root metabolism.

* **Liquid Level Sensors:** Monitor the volume of solution in the main reservoir, triggering alerts or refill actions.

* **Environmental Sensors (Optional):** Integration may include air temperature, humidity, and Photosynthetic Photon Flux Density (PPFD) sensors within the growing environment.

#### 2. Actuation and Control Loops

The microcontroller processes the sensor data and executes automated responses using actuators:

* **Nutrient Dosing:** Peristaltic pumps or solenoid valves inject concentrated stock nutrient solutions (A and B) into the reservoir when the EC reading falls below the programmed setpoint.

* **pH Chemigation:** Separate dosing pumps inject pH Up (base) or pH Down (acid) solutions to automatically correct drift in the pH level, maintaining homeostasis.

* **Pump Control:** The system manages the timing and duration of the main submersible pump operation (the feeding schedule).

* **Remote Connectivity:** Data is transmitted wirelessly (Wi-Fi, MQTT protocol) to a local server or cloud platform (e.g., AWS IoT, Google Cloud). This allows for real-time visualization, historical logging, and remote adjustment of setpoints by the operator via a web dashboard or mobile application.

### Operational Advantages

The IOT Dutch Bucket setup offers substantial efficiency benefits compared to conventional horticulture or non-automated hydroponic systems:

1. **Precision Nutrient Management:** Continuous, automated adjustment of EC and pH ensures plants receive optimal feeding, eliminating nutrient lockout or toxicity issues caused by fluctuation.

2. **Water Conservation:** The recirculating nature minimizes water loss, primarily limiting consumption to plant transpiration and minor evaporation.

3. **Scalability and Modularity:** The Dutch Bucket structure allows easy expansion by adding more pots without redesigning the core fluid dynamics.

4. **Predictive Maintenance:** Data logging enables the identification of systemic issues (e.g., pump failure, sensor drift) before they critically impact crop health.

KEYWORDS: Hydroponics, IOT, Dutch Bucket, Recirculating, Bato Bucket, CEA, Automation, Peristaltic Pump, EC Sensor, pH Sensor, Nutrient Management, Chemigation, Drip System, Plant Pot, Microcontroller, Actuator, Solenoid Valve, Reservoir, Substrate, Perlite, Coco Coir, Remote Monitoring, Precision Agriculture, Data Logging, Horticulture, Modular System, Root Zone, Fertigation, Closed-Loop Control, Wi-Fi.

Need more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Free Format ConversionWe do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

Usage Information

IOT PLANT POT RECIRCULATING HYDROPONIC DUTCH BUCKET SYSTEM SETUP - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी