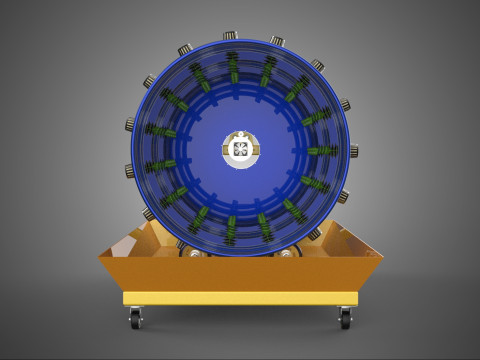

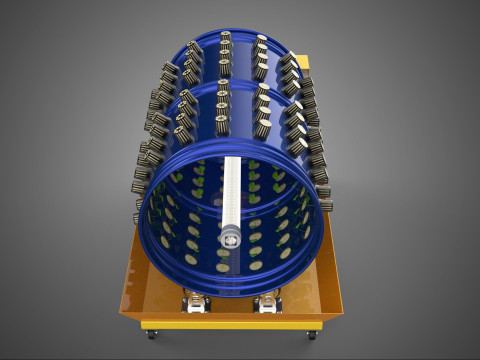

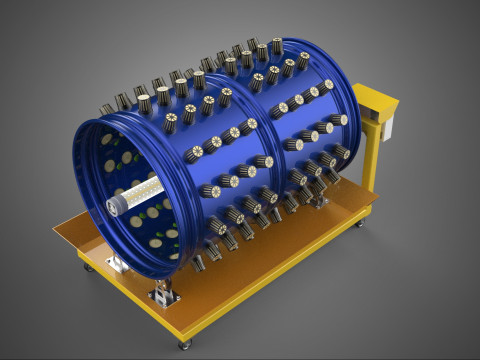

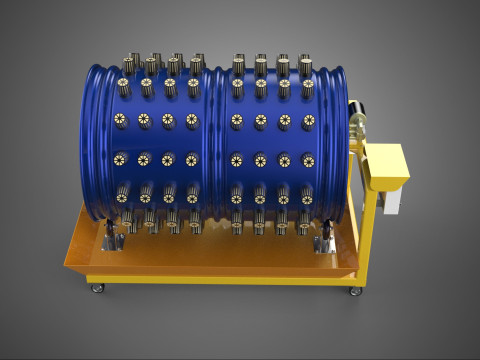

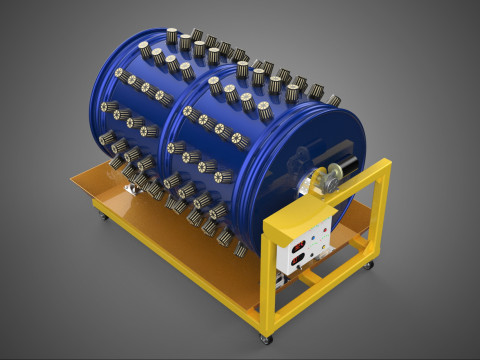

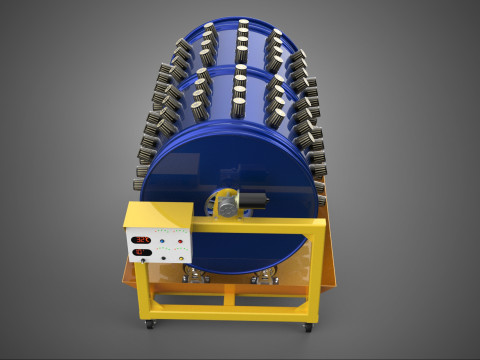

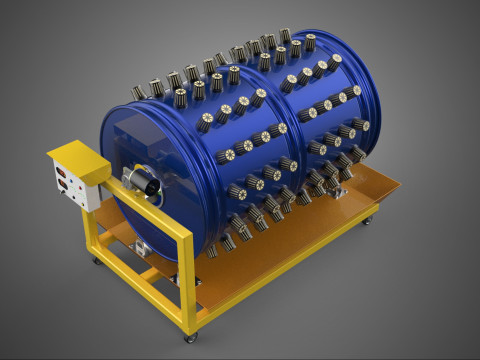

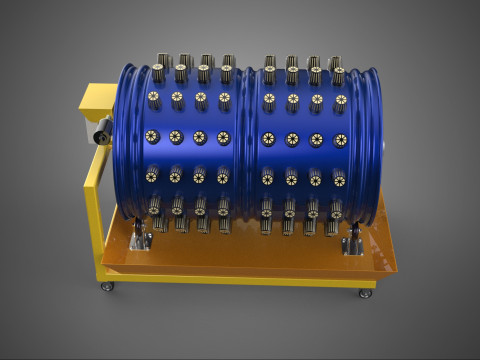

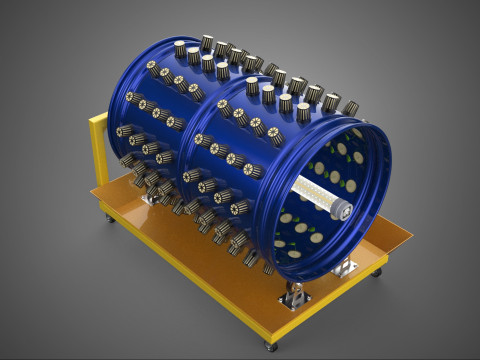

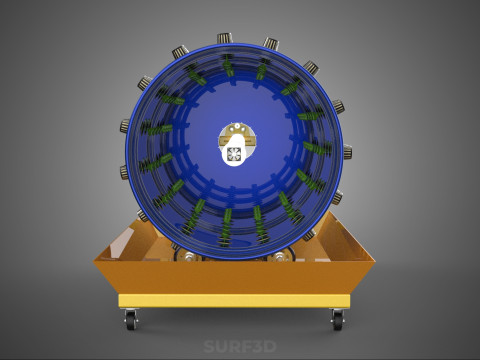

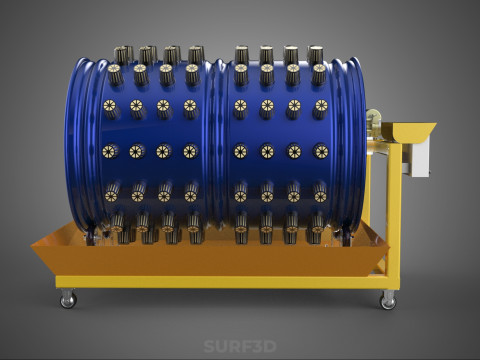

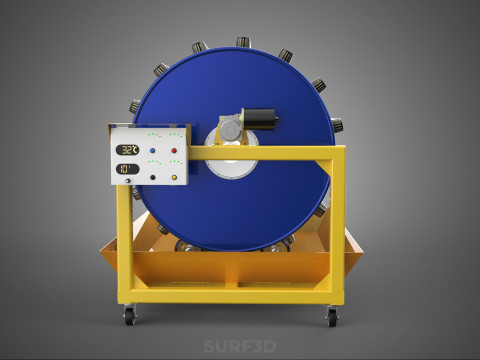

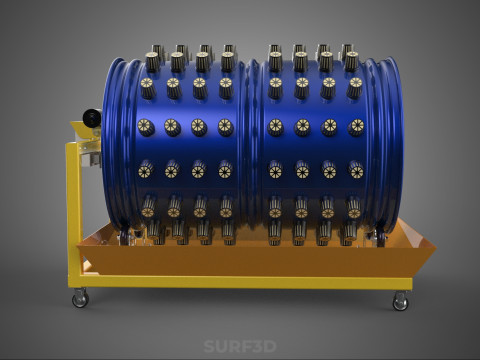

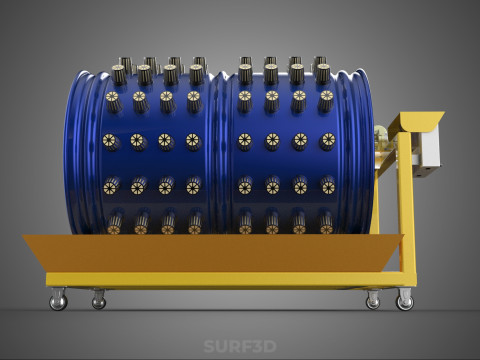

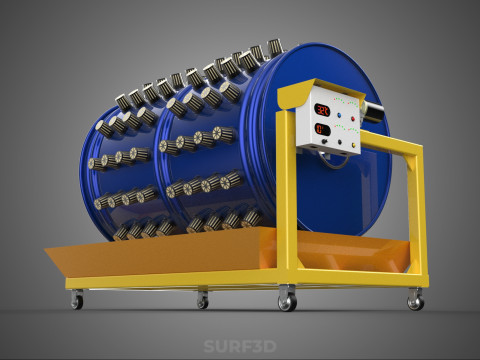

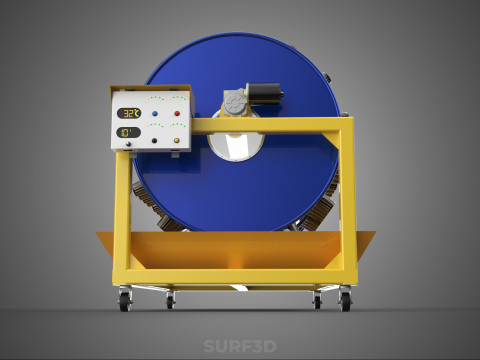

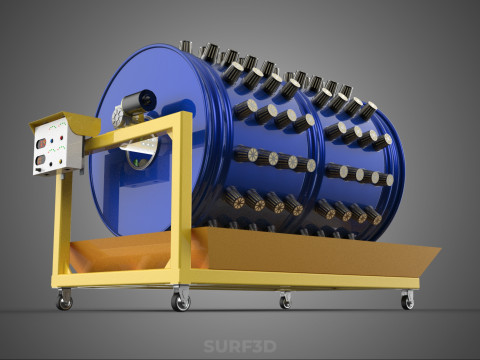

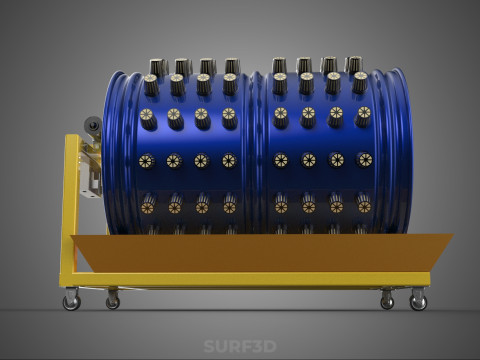

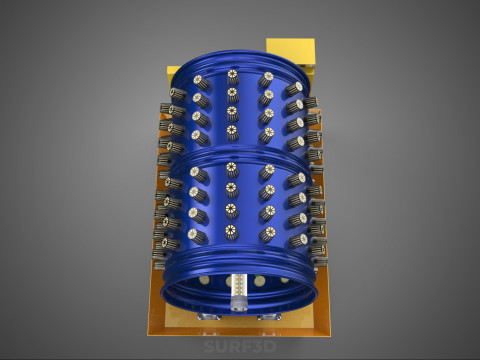

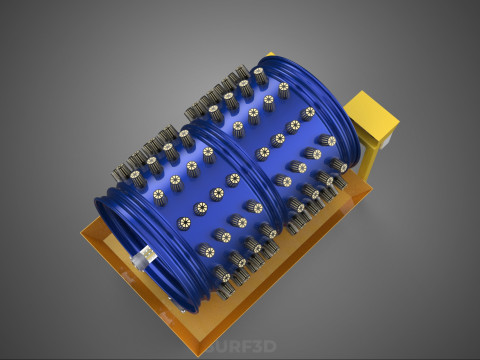

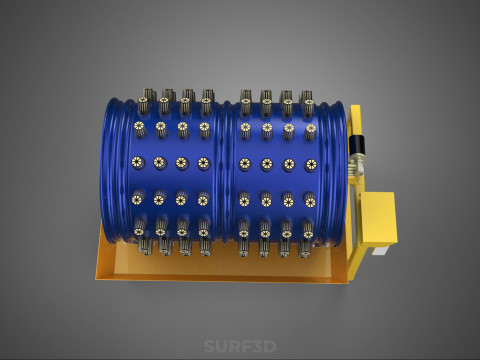

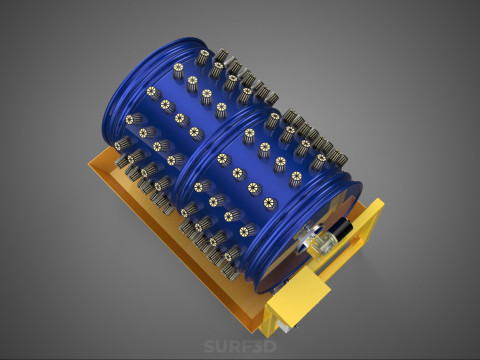

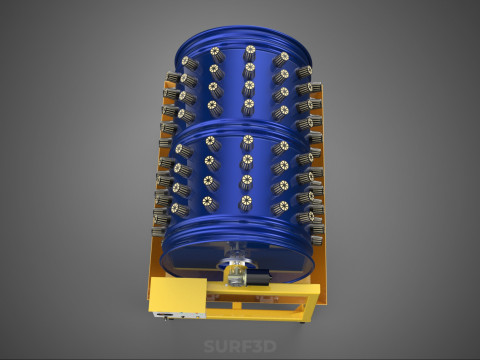

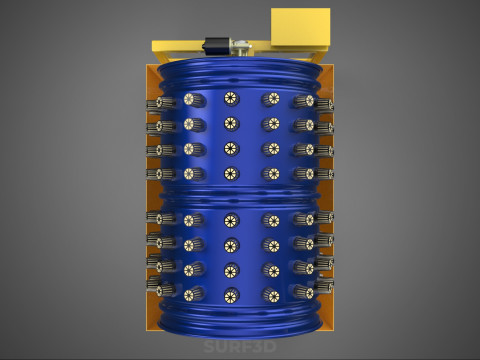

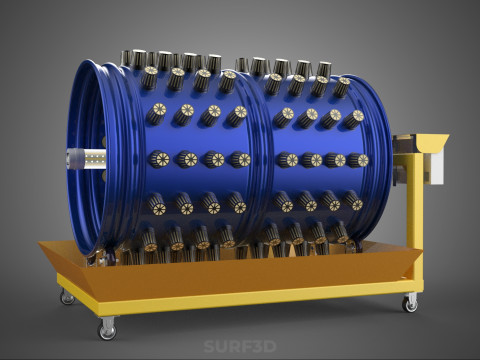

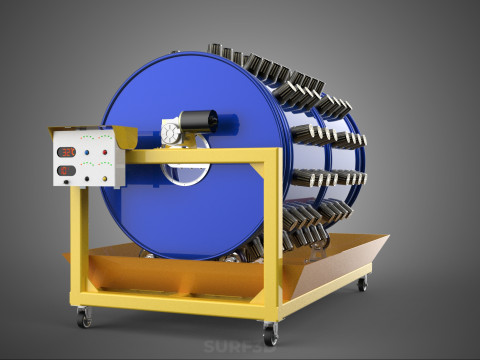

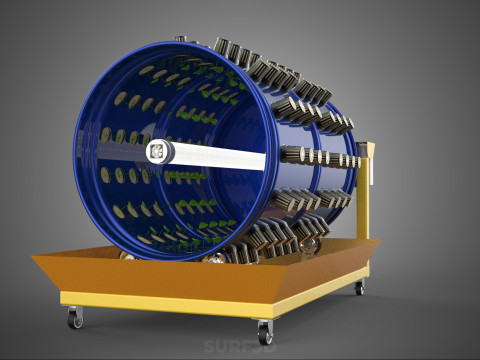

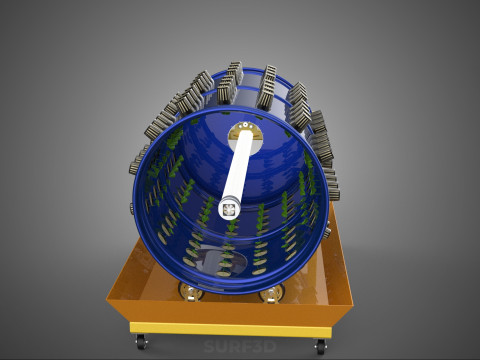

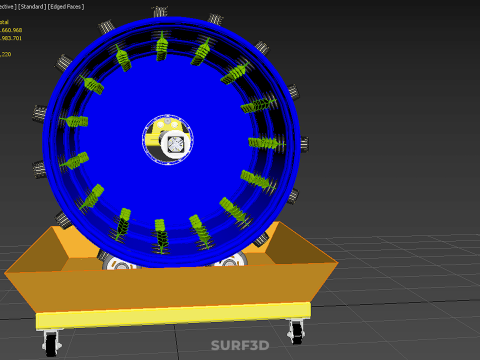

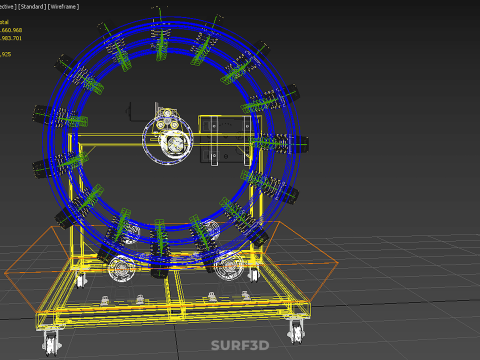

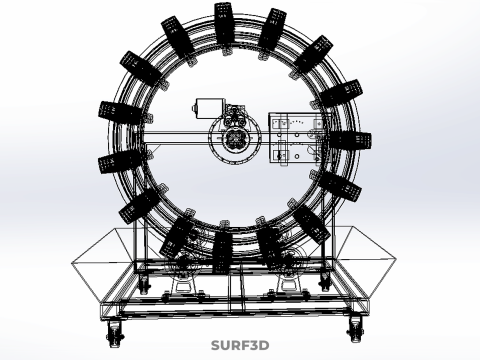

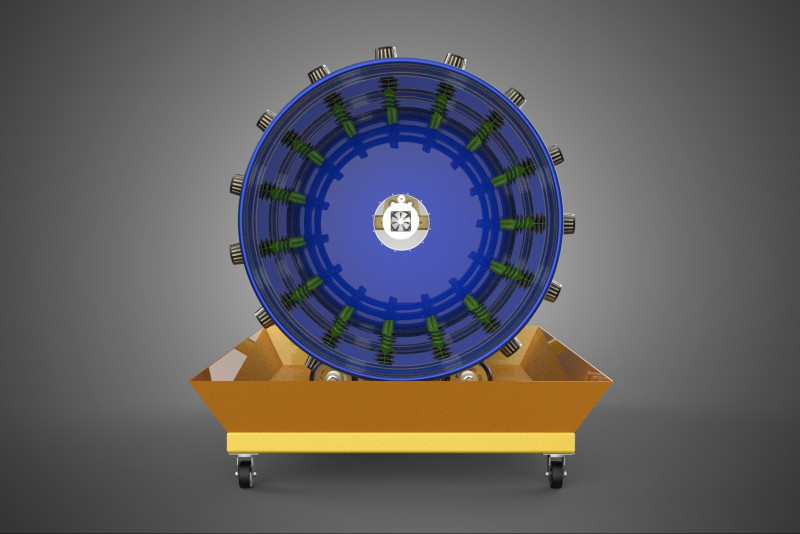

ROTARY HYDROPONICS RADIAL SPIN GARDENING PLANT FARM SYSTEM WHEEL 3D Model

- Request product support by the author

- Available formats:

- Item ID:603552

- Date: 2025-10-05

- Polygons:3660968

- Vertices:2983701

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Poly NURBS

- Unwrapped UVs:Unknown

- Views:192

Description

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely *******ed formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software *******

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

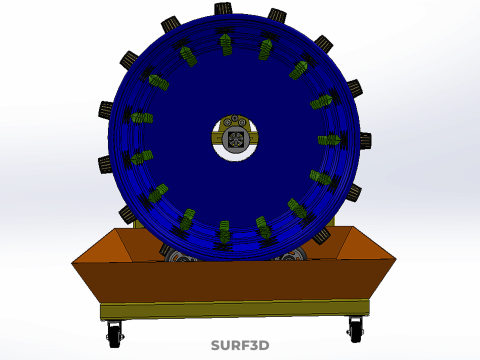

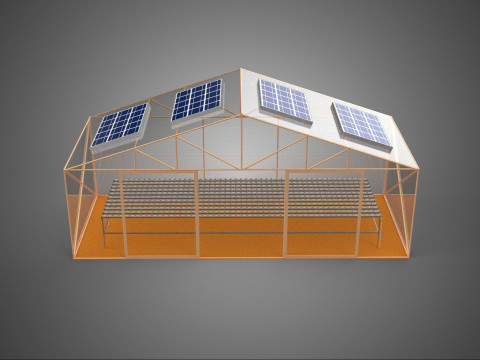

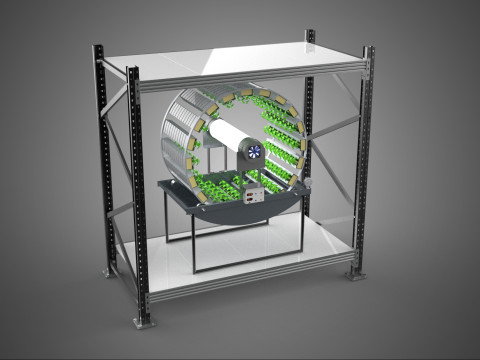

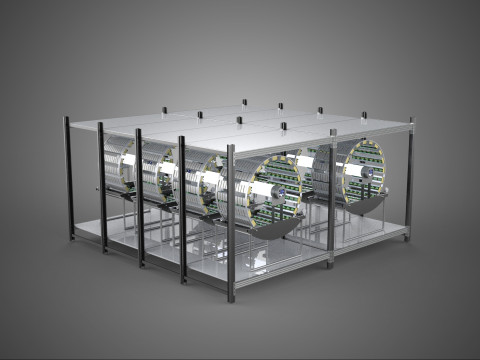

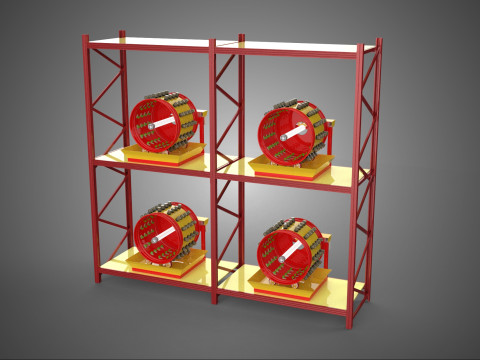

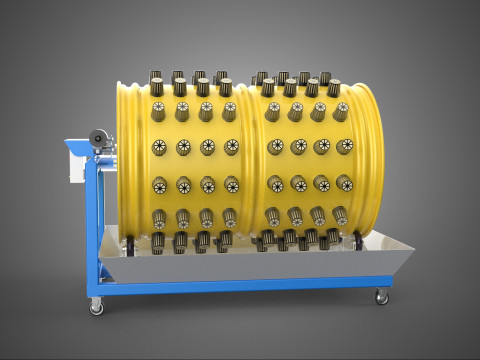

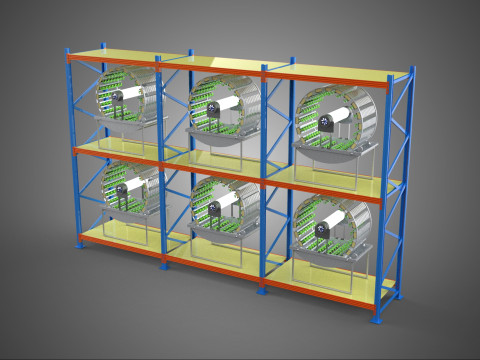

**Rotary Hydroponics Radial Spin Gardening Plant Farm System Wheel**

A Rotary Hydroponics Radial Spin Gardening Plant Farm System Wheel, frequently identified as a rotary hydroponic garden, vertical rotary garden, or circular hydroponic system, represents an advanced form of Controlled Environment Agriculture (CEA). This innovative system integrates hydroponic plant cultivation with a mechanized, rotating, wheel-like structure designed to optimize plant density and resource efficiency within a constrained physical footprint. Plants are arranged radially around a central axis and subjected to continuous or intermittent rotation.

**Principle of Operation:**

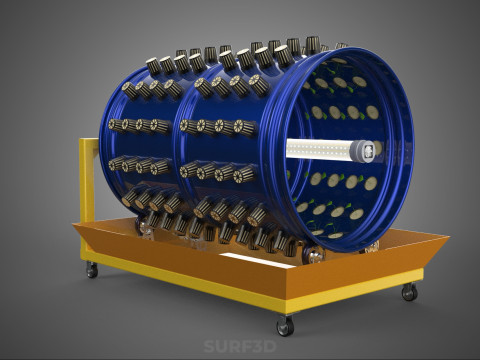

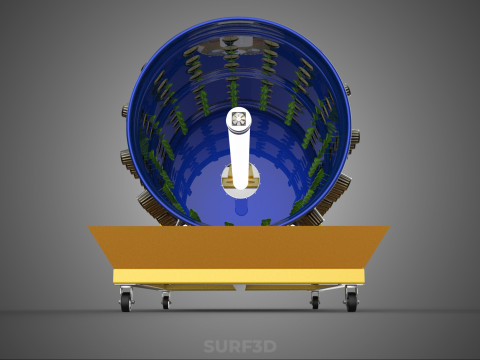

The core operational principle involves the soilless cultivation of plants (hydroponics) within a rotating cylindrical or discoid framework. Plants are typically housed in individual growing receptacles, such as net pots or rockwool cubes, which are securely positioned within openings along the periphery or face of the rotating wheel. A precisely formulated, nutrient-rich water solution is delivered to the plant roots, often via a recirculating pump system. Common hydroponic methods employed include Nutrient Film Technique (NFT), Deep Water Culture (DWC), or aeroponics, where roots are periodically misted with the nutrient solution.

The distinguishing feature of this system is the controlled rotational movement of the entire plant array. This rotation serves several critical functions:

1. **Uniform Light Distribution:** By continuously rotating the plants, all sections of each plant receive equitable exposure to a stationary central light source (e.g., high-intensity discharge lamps or LEDs) or strategically positioned external peripheral lighting. This mitigates issues of etiolation and ensures consistent, balanced growth across the entire system.

2. **Space Optimization:** The vertical and radial arrangement allows for a significantly higher plant count per unit of floor area compared to traditional horizontal farming methods. This high-density cultivation makes such systems exceptionally well-suited for urban and indoor agricultural settings where space is at a premium.

3. **Enhanced Aeration (Aeroponic Variants):** In systems employing aeroponics, the rotational movement can contribute to improved air circulation around the root zone, potentially enhancing oxygen uptake and nutrient absorption. While some theories suggest direct centrifugal growth enhancement, the primary and well-established benefits are generally attributed to optimized light and nutrient delivery.

**Key Components:**

A typical Rotary Hydroponics Radial Spin Gardening Plant Farm System Wheel comprises several integrated components:

* **Structural Wheel/Frame:** The primary ******* structure, often constructed from durable, corrosion-resistant materials (e.g., PVC, food-grade plastics, aluminum), engineered to securely hold plant containers and withstand continuous rotational stress.

* **Growing Chambers/Ports:** Individual openings, pockets, or net pot baskets integrated within the wheel where plants are rooted and *******ed.

* **Central Motor and Drive System:** An electric motor coupled with a gearing mechanism, responsible for providing the controlled, often slow (e.g., one revolution per hour or per day), rotation of the entire wheel.

* **Lighting System:** High-efficiency grow lights, predominantly Light Emitting Diodes (LEDs), strategically positioned centrally within the wheel's core or around its exterior to provide optimal Photosynthetic Active Radiation (PAR) for plant growth.

* **Nutrient Reservoir and Pump:** A storage tank containing the pre-mixed nutrient solution, connected to a pump that precisely delivers the solution to the plant roots.

* **Irrigation System:** Tubing, misters, or trays designed to distribute the nutrient solution effectively to each plant within the rotating array.

* **Controller/Timer:** An automated system used to manage critical parameters such as light cycles, pump schedules, rotation speed, and often monitors and adjusts nutrient pH and electrical conductivity (EC).

**Advantages:**

* **High-Density Cultivation:** Maximizes yield per unit of floor area, which is crucial for environments with limited space.

* **Resource Efficiency:** Significantly reduces water consumption (up to 90% less than traditional soil-based farming) through nutrient solution recirculation. Nutrient use is also highly optimized.

* **Accelerated Growth Rates:** Consistent light exposure, uniform nutrient delivery, and environmental control often lead to faster plant growth and shorter crop cycles, enhancing productivity.

* **Controlled Environment:** Facilitates precise control over environmental factors such as temperature, humidity, and CO2 levels. This also creates a barrier against pests and diseases, minimizing the need for pesticides.

* **Ergonomics:** Depending on the design, these systems can offer improved ergonomic access to plants for monitoring, maintenance, and harvesting compared to some other vertical farming methods.

**Limitations and Considerations:**

* **Initial Investment:** The complexity of the mechanical and automated components typically results in higher upfront capital costs compared to simpler hydroponic setups.

* **Energy Consumption:** Requires continuous power for lighting, the motor, and pumps, which can represent a substantial operational cost depending on the system's scale and light intensity.

* **Technical Complexity:** Demands a certain level of technical understanding for proper setup, nutrient management, and troubleshooting of mechanical and electrical components.

* **Plant Suitability:** Best suited for relatively compact, fast-growing crops such as leafy greens (e.g., lettuce, spinach, kale), culinary herbs, and small fruiting plants (e.g., strawberries), rather than large or tall crops.

**Applications:**

These systems are increasingly adopted in various sectors, including urban agriculture, indoor commercial farms, educational institutions for demonstrating advanced horticultural practices, and agricultural research facilities.

Need more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Free Format ConversionWe do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

Usage Information

ROTARY HYDROPONICS RADIAL SPIN GARDENING PLANT FARM SYSTEM WHEEL - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी