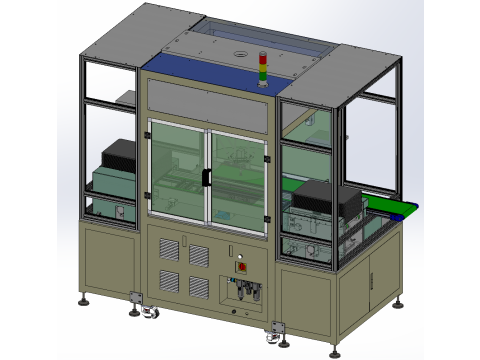

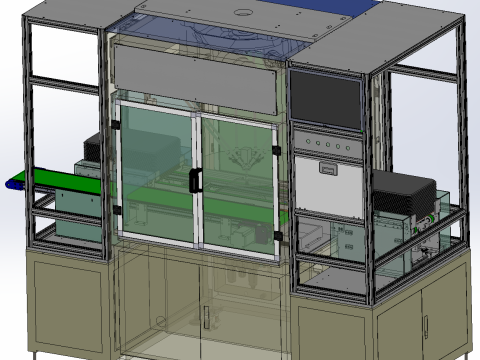

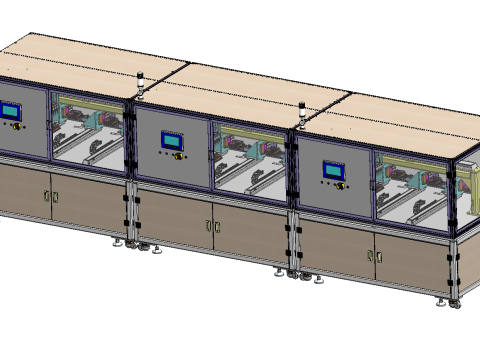

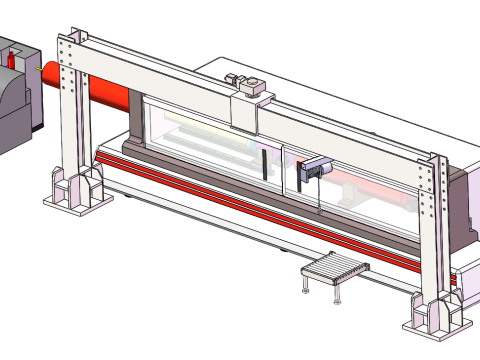

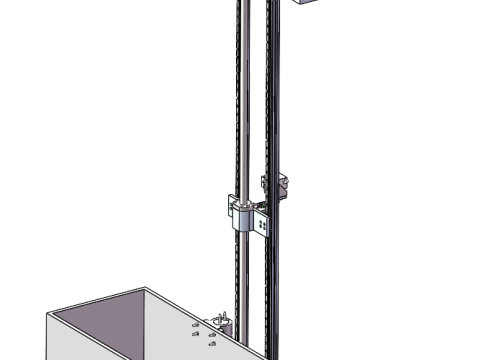

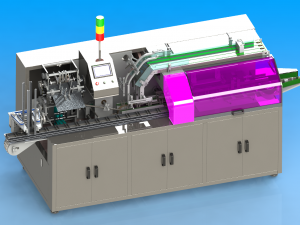

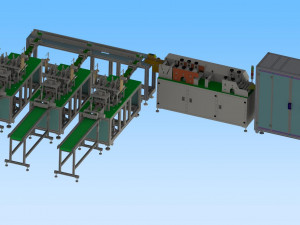

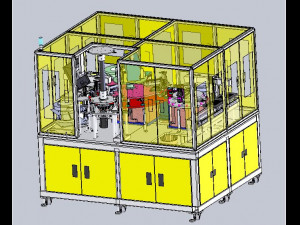

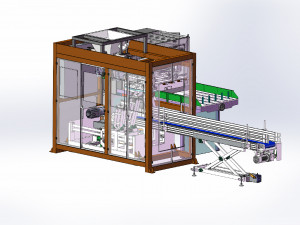

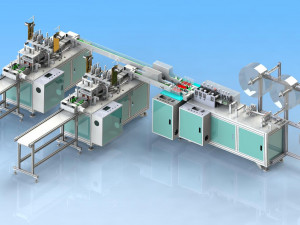

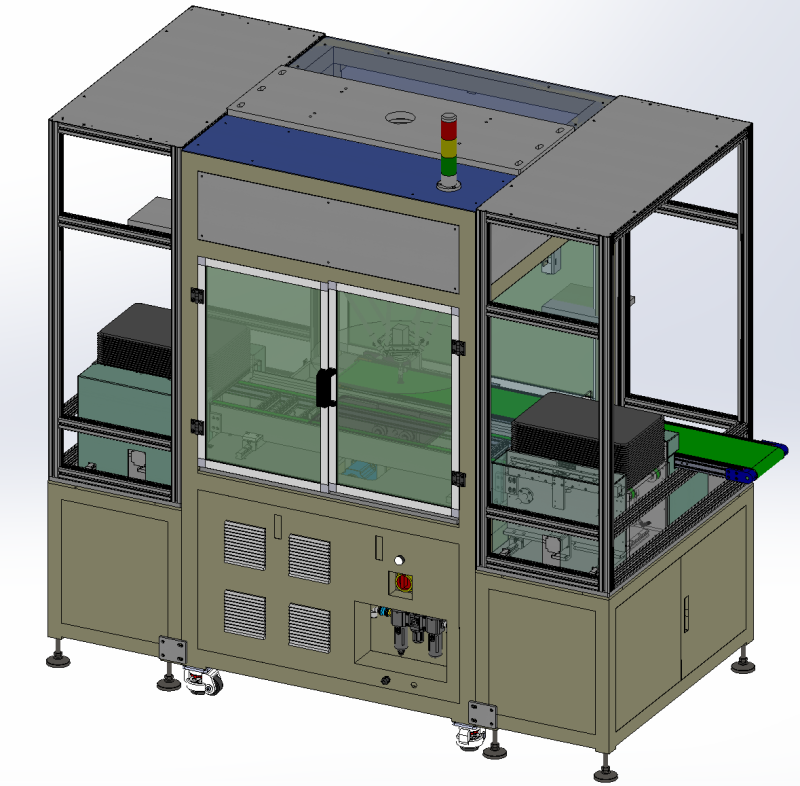

Spider hand disc machine SolidWorks editable 3D Model

- Request product support by the author

- Available formats:

- Item ID:615540

- Date: 2025-12-04

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Polygonal

- Unwrapped UVs:Unknown

- Views:241

Description

Spider hand disc machine SolidWorks editable

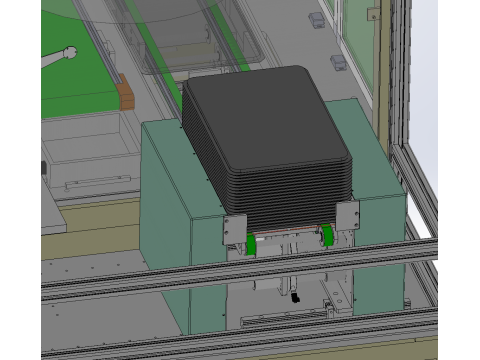

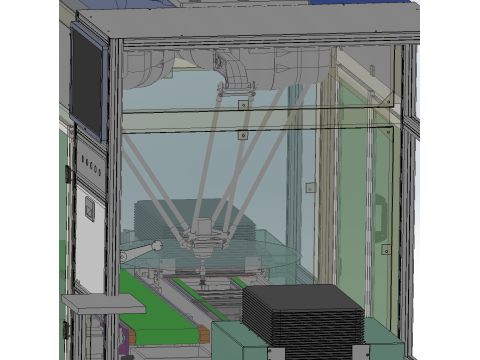

Spider hand disc machine is an automated equipment that uses three-axis or four axis parallel robots, mainly used for automatic disc loading and swinging work. It is equipped with visual inspection (on demand) and quickly draws materials into steel trays through suction tools. The spider hand disc machine has the characteristics of high speed and excellent stability, and is an essential key equipment for bagged materials (with sterilization process requirements) to enter and exit the sterilization kettle. The main components of a spider hand disc machine include a material conveying device, a spider hand parallel robot, and a disc conveying device. The material conveying device is responsible for transporting the materials to be loaded onto the tray to the designated location; The spider hand parallel robot is responsible for grabbing materials and moving them along a predetermined trajectory to achieve automatic loading and swinging of the tray; The plate conveying device transports the plates loaded with plates to the next stage. By introducing a spider hand parallel robot, the spider hand disc placement machine has achieved automatic disc loading and placement. In addition, the spider hand disc machine also has the following advantages: the robot's operating speed is much higher than manual labor, and it can process a large amount of materials in a short period of time. Improve accuracy: The operational accuracy of robots is higher than that of manual labor, ensuring that each material is placed on the plate according to a uniform standard. Reduce labor costs: Robots can work continuously without taking breaks, thereby reducing labor costs. Improving product quality: Due to the high operational accuracy of robots, the quality of products can be guaranteed. Looking ahead, with technological advancements, the application areas of spider hand parallel robots will continue to expand. In addition to the field of food processing, spider hand plate placement machines can also be applied to other fields that require automatic plate loading and placement, such as medicine, logistics, etc.

Print Ready: NoNeed more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Free Format ConversionWe do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

Usage Information

Spider hand disc machine SolidWorks editable - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский 中國

中國 हिंदी

हिंदी