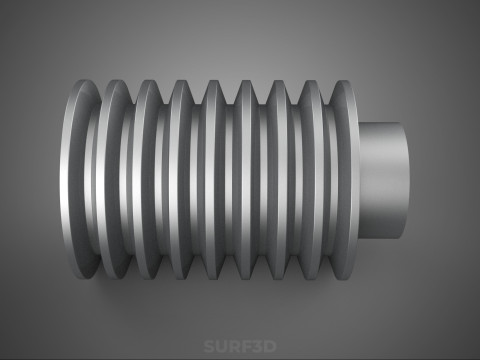

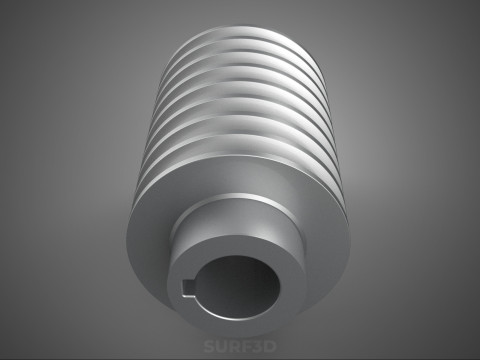

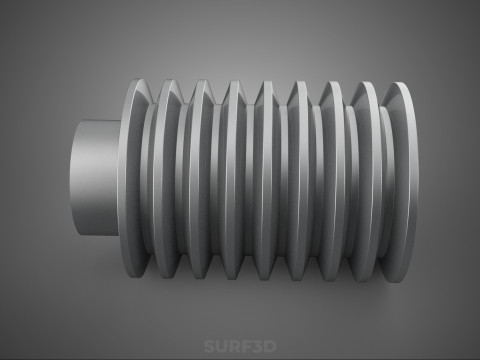

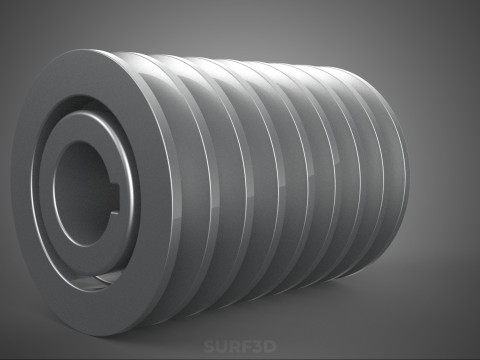

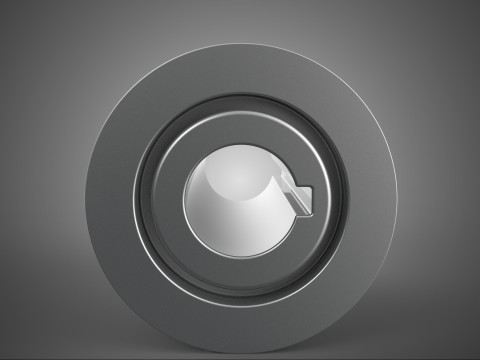

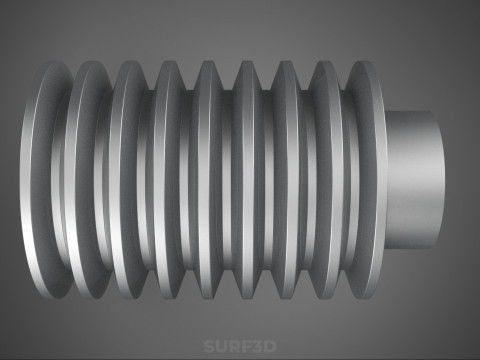

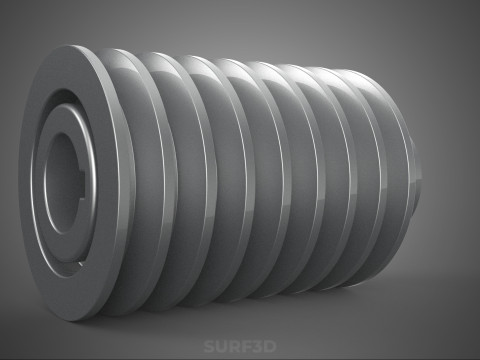

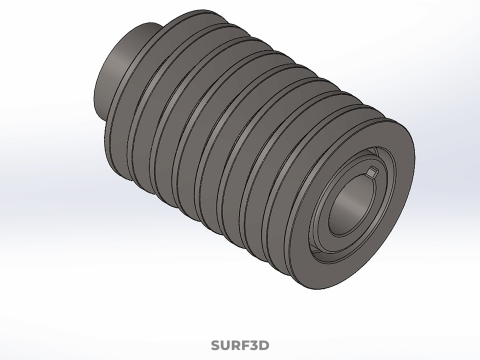

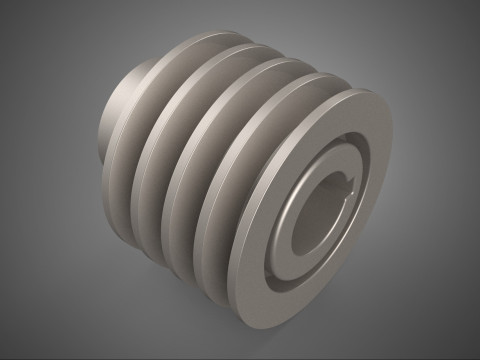

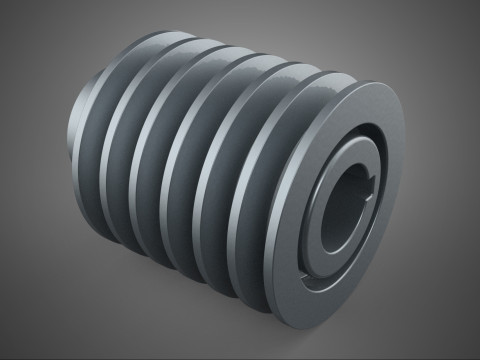

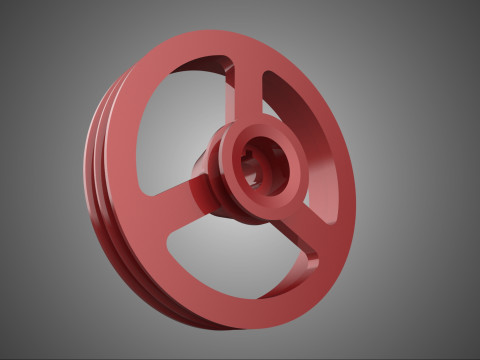

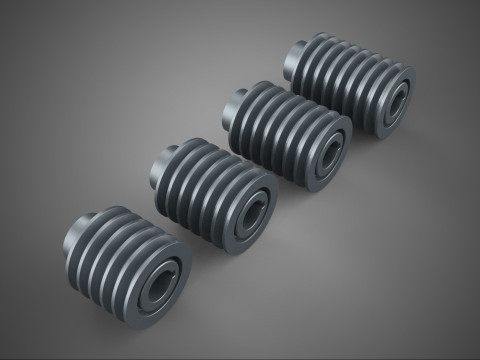

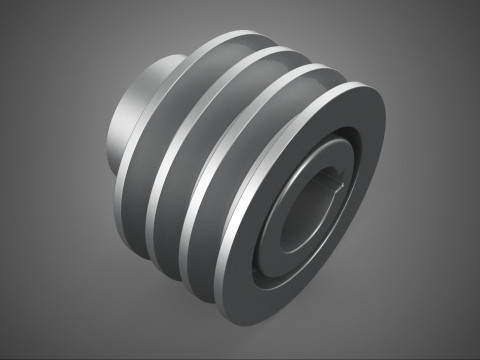

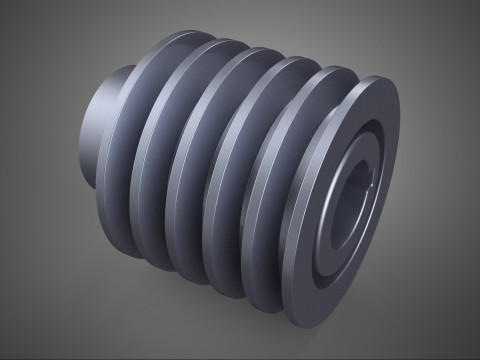

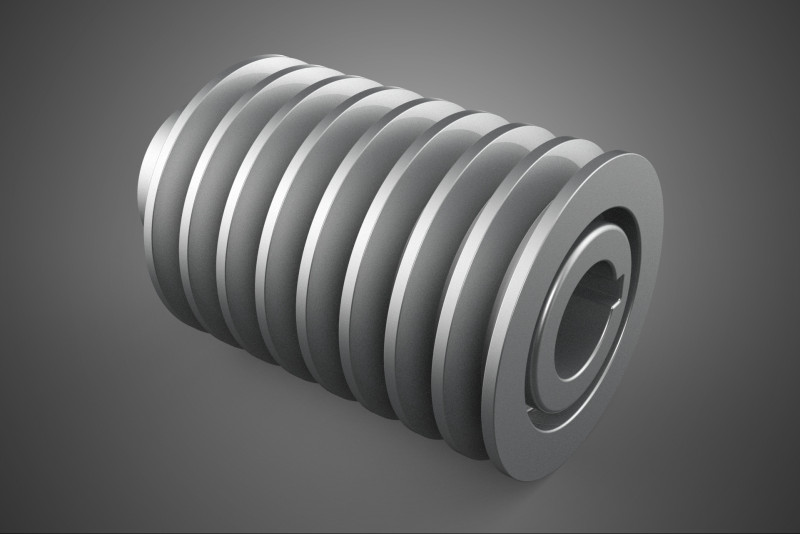

STANDARD 8 EIGHT OCTUPLE GROOVE TRACK PULLEY SHEAVE WHEEL V BELT 3D Model

- Request product support by the author

- Available formats:

- Item ID:622220

- Date: 2026-01-09

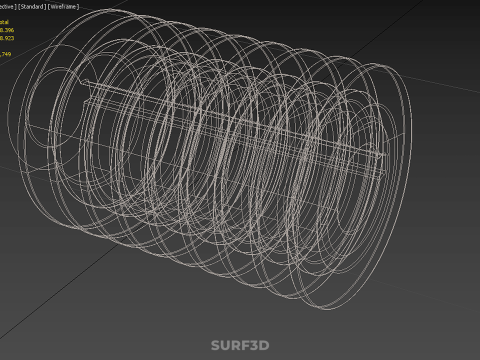

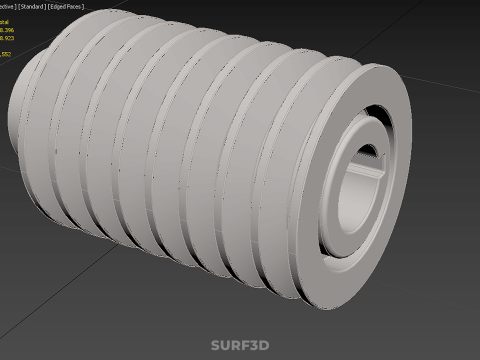

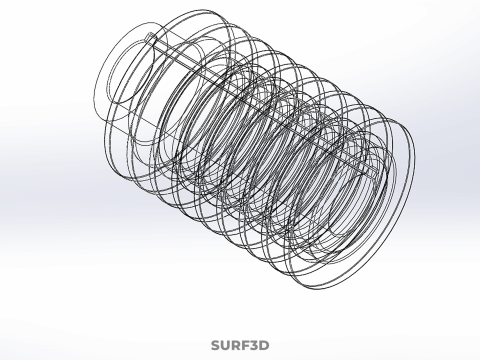

- Polygons:28396

- Vertices:18923

- Animated:No

- Textured:No

- Rigged:No

- Materials:

- Low-poly:No

- Collection:No

- UVW mapping:No

- Plugins Used:No

- Print Ready:No

- 3D Scan:No

- Adult content:No

- PBR:No

- AI Training:No

- Geometry:Poly NURBS

- Unwrapped UVs:Unknown

- Views:216

Description

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

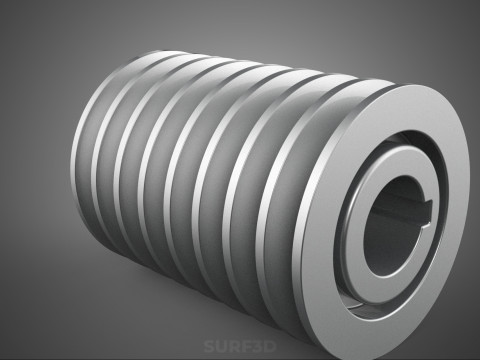

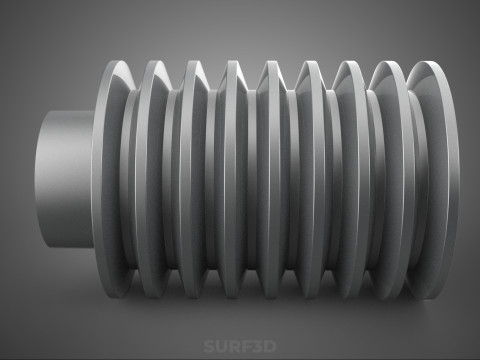

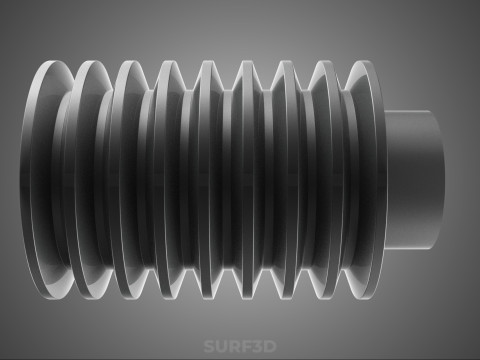

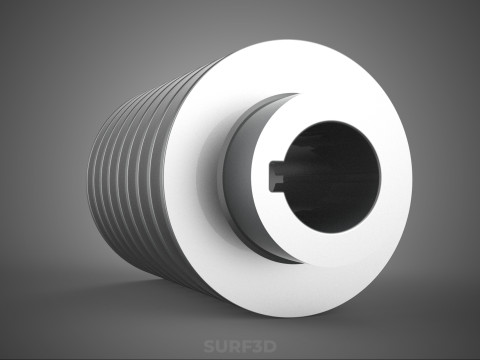

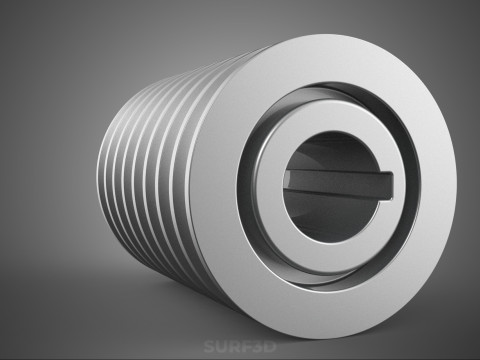

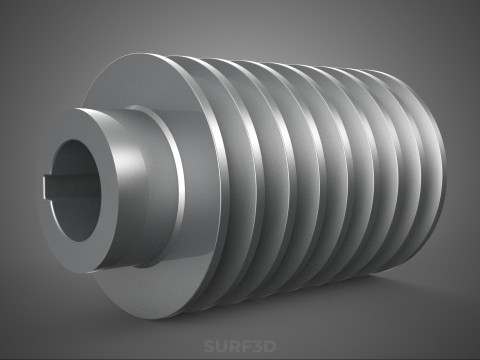

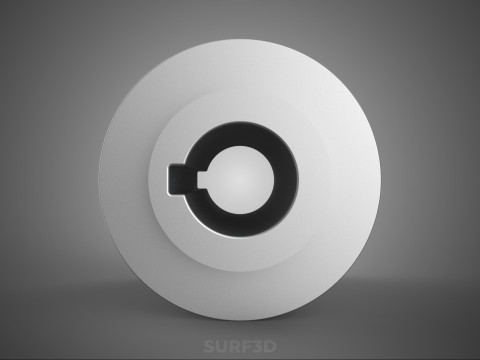

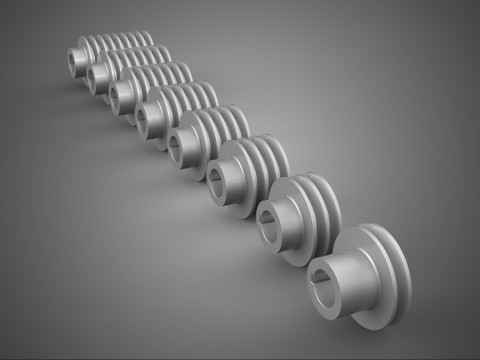

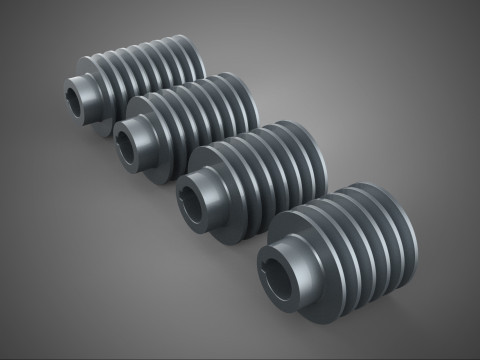

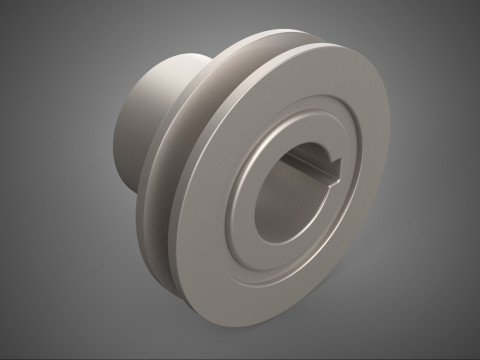

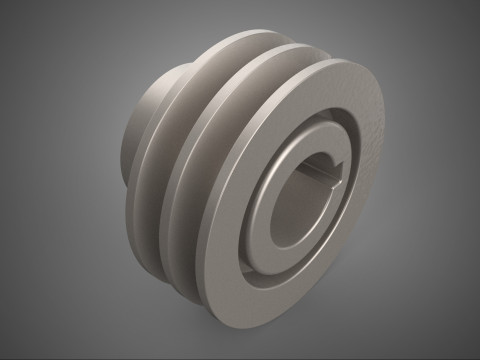

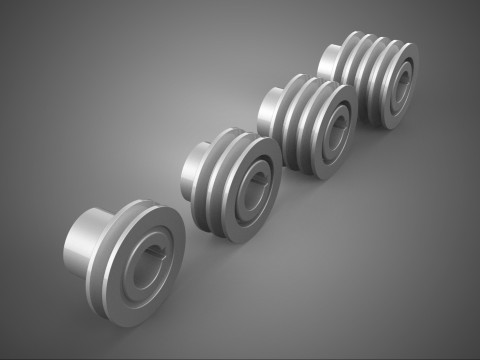

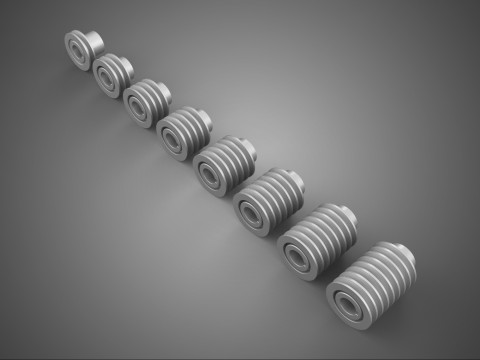

A Standard Eight (8), Octuple-Groove Track Pulley Sheave Wheel designed for V-Belts is a critical mechanical component utilized in high-capacity power transmission systems. This specialized sheave is defined by the presence of eight parallel, circumferentially machined grooves, enabling the simultaneous engagement of eight individual V-belts or a single, specialized eight-ribbed banded belt. The standardized geometry ensures interchangeability and adherence to stringent industrial specifications regarding dimensions, materials, and operational tolerance.

### Nomenclature and Standardization

The component is frequently referenced using several synonymous terms—pulley, sheave, track wheel, and belt wheel—all referring to the disc mounted on a rotating shaft designed to transfer torque. The term "STANDARD" dictates that the sheave adheres to established specifications, such as those promulgated by the International Organization for Standardization (ISO), the American National Standards Institute (ANSI), or specific regional bodies (e.g., DIN standards in Germany). These standards govern critical dimensions including the pitch diameter, the groove angle (typically 34° to 38° depending on the specific V-belt profile, such as 3V, 5V, 8V, A, B, or C), the groove spacing (pitch), and the maximum allowable runout. Adherence to these standards ensures mechanical compatibility and predictable performance when integrating the sheave into standardized V-belt drives.

### Design and Octuple Geometry

The octuple-groove configuration is specifically engineered to maximize the operational capacity (horsepower and torque) of the belt drive system. By distributing the load across eight distinct contact surfaces, the design achieves superior mechanical advantages over single or dual-groove systems. Key design features include:

1. **Load Distribution:** The multiple-track design ensures even distribution of tensile forces and frictional load, minimizing localized stress concentration on individual belts or tracks. This substantially increases the service life and reliability of the entire system.

2. **Increased Contact Area:** The cumulative surface area provided by the eight grooves maximizes the frictional grip between the sheave and the belts, thereby reducing the risk of slip, especially under peak or shock loads.

3. **Dynamic Balancing:** Due to the inherent high-speed operation often associated with octuple-groove systems, the sheave must be dynamically balanced during manufacturing. This ensures minimal vibration, reduced bearing wear, and consistent power delivery throughout the operational speed range.

The hub of the sheave is typically manufactured to accept standard bore configurations, frequently incorporating standardized bushing systems such as Taper-Lock, QD (Quick Detachable), or split-taper bushings, which facilitate secure mounting and ease of removal from the shaft.

### Materials and Fabrication

Standard 8-track sheaves are fabricated from materials selected for high tensile strength, excellent wear resistance, and shock absorption capacity. The most common material is high-grade gray cast iron (e.g., ASTM A48 Class 30 or 35), which provides damping qualities necessary for industrial applications. For extremely high-speed or corrosion-prone environments, ductile iron, forged steel, or sometimes specialized aluminum alloys are employed.

Fabrication involves precision casting followed by stringent CNC machining processes. The groove contours are machined to strict tolerances to ensure the correct seating depth and angle for the corresponding V-belt profile, which is crucial for achieving optimal mechanical efficiency and minimizing belt wear.

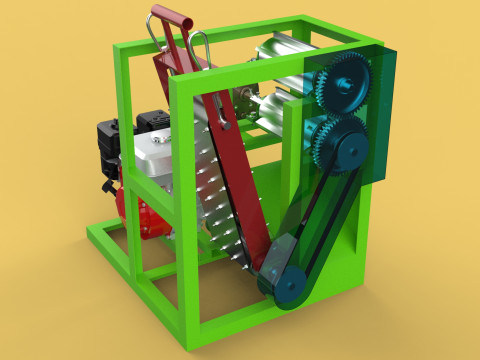

### Industrial Applications

The Standard Octuple-Groove Pulley is essential in heavy-duty industrial contexts where continuous operation, high power throughput, and reliability are non-negotiable requirements. Primary applications include:

* Large industrial compressors and blowers.

* Heavy-duty crushing, grinding, and milling equipment.

* Main drives for pumps in large-scale fluid transfer operations.

* Power generation equipment and large gearbox input drives.

* High-capacity heating, ventilation, and air conditioning (HVAC) systems.

KEYWORDS: Pulley, Sheave, Octuple Groove, 8-Track, V-Belt Drive, Power Transmission, Multi-Groove, Standard Pulley, Drive System, Mechanical Component, Synchronous Drive, High Capacity, Load Distribution, Cast Iron Sheave, Industrial Machinery, ANSI Standard, ISO Standard, Taper-Lock, QD Bushing, Pitch Diameter, Effective Diameter, Belt Slip, Rotational Energy, Compressor Drive, HVAC System, V-Belt Profile, High Torque, Standard Specification, Eight Groove, Mechanical Efficiency.

Need more formats?

If you need a different format, please send us a Conversion Request. We can convert 3D models to: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Free Format ConversionWe do not convert 3d scenes and solid formats such as .step, .iges, .stp, .sldprt etc!

Usage Information

STANDARD 8 EIGHT OCTUPLE GROOVE TRACK PULLEY SHEAVE WHEEL V BELT - You can use this royalty-free 3D model for both personal and commercial purposes in accordance with the Basic or Extended License.The Basic License covers most standard use cases, including digital advertisements, design and visualization projects, business social media accounts, native apps, web apps, video games, and physical or digital end products (both free and sold).

The Extended License includes all rights granted under the Basic License, with no usage limitations, and allows the 3D model to be used in unlimited commercial projects under Royalty-Free terms.

Read more

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский 中國

中國 हिंदी

हिंदी